Problem Solved!

Visit Us:

Amerimold Booth #535

September 21-23

Rosemont, IL

Tim Lankisch

Director of Engineering

TUESDAY, 11am - September 21, 2021

Topic: Windage Analysis

Simulation Proves Significant in Rapid Response for

Ventilator Production

When the COVID-19 pandemic struck last year, nobody could have predicted what the world was up against. With dire predictions and little time to react, the medical community had to respond quickly. A large part of that community was the plastics industry, who stepped up and got the job done. One major project was taken on by General Motors to leverage their supply chain to mass-produce 30,000 ventilators for Ventec Life Systems.

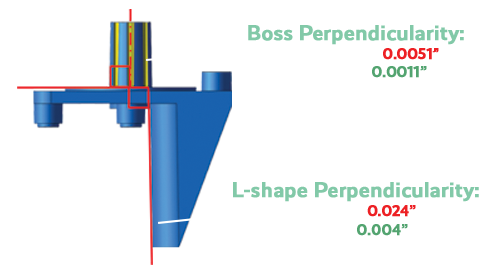

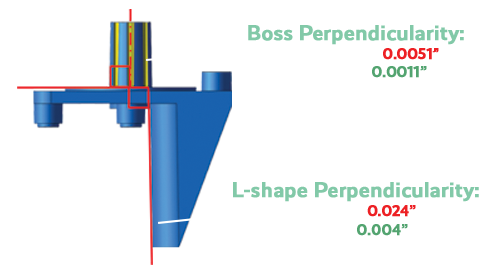

With some 700 parts required to make one ventilator, many of which are injection molded, the task to ramp up tooling and production was monumental, to say the least. CAE Services Corporation was called upon to work on several parts for the ventilator, one of which was a bracket needed for an oxygen-metering valve assembly. Using Moldflow to identify the best way to meet very tight tolerances on a short timeline proved to be just the cure to help flatten the curve.

Visit Us:

Amerimold Booth #535September 21-23Rosemont, IL

REGISTER HERE

Tim LankischDirector of Engineering

TUESDAY, 11am – September 21, 2021

Topic: Windage Analysis

Simulation Proves Significant in Rapid Response for Ventilator Production

When the COVID-19 pandemic struck last year, nobody could have predicted what the world was up against. With dire predictions and little time to react, the medical community had to respond quickly. A large part of that community was the plastics industry, who stepped up and got the job done. One major project was taken on by General Motors to leverage their supply chain to mass-produce 30,000 ventilators for Ventec Life Systems.

With some 700 parts required to make one ventilator, many of which are injection molded, the task to ramp up tooling and production was monumental, to say the least. CAE Services Corporation was called upon to work on several parts for the ventilator, one of which was a bracket needed for an oxygen-metering valve assembly. Using Moldflow to identify the best way to meet very tight tolerances on a short timeline proved to be just the cure to help flatten the curve.