Ask The Moldflow Experts

Cooling Analysis - What's Best For You?

Ask The Moldflow Experts Webinar Topic:

Cooling Analysis - What's Best For You?

- How cooling analysis works

- What are the different types of cooling analysis that are available?

ATME - Take Away

Key Cooling Message

- The fundamentals don’t change

- How do we take advantage of them?

- There are different types of Moldflow cooling analysis

- Cooling designs shouldn’t be an afterthought

- Cooling uniformity and efficiency can be improved PROACTIVELY

Cooling Uniformity

Pitch Controls Surface Uniformity

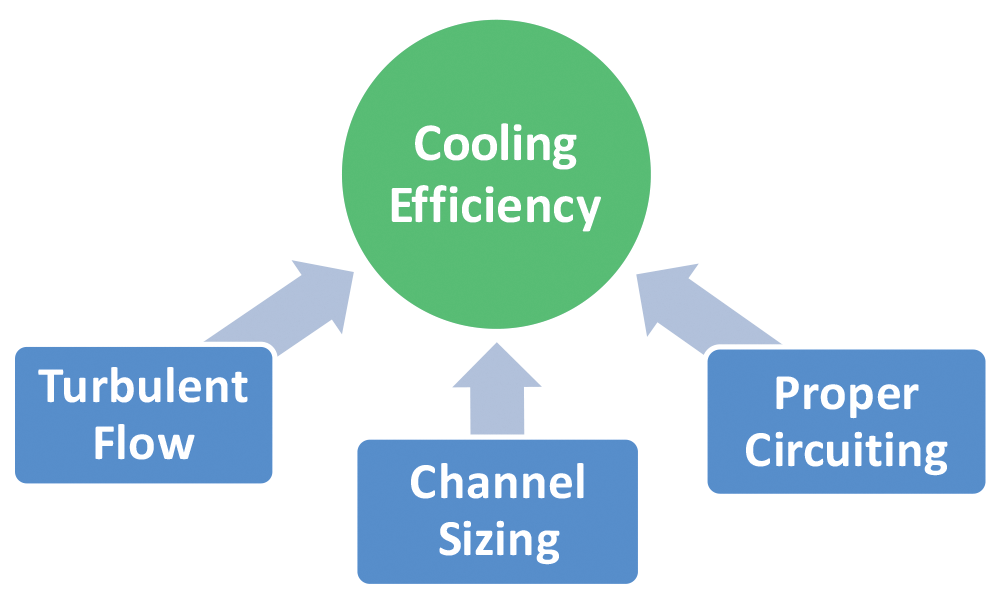

Improving Cooling Uniformity

-

Solution 1 – Add/move water

-

Solution 2 – Higher Conductivity Inserts

-

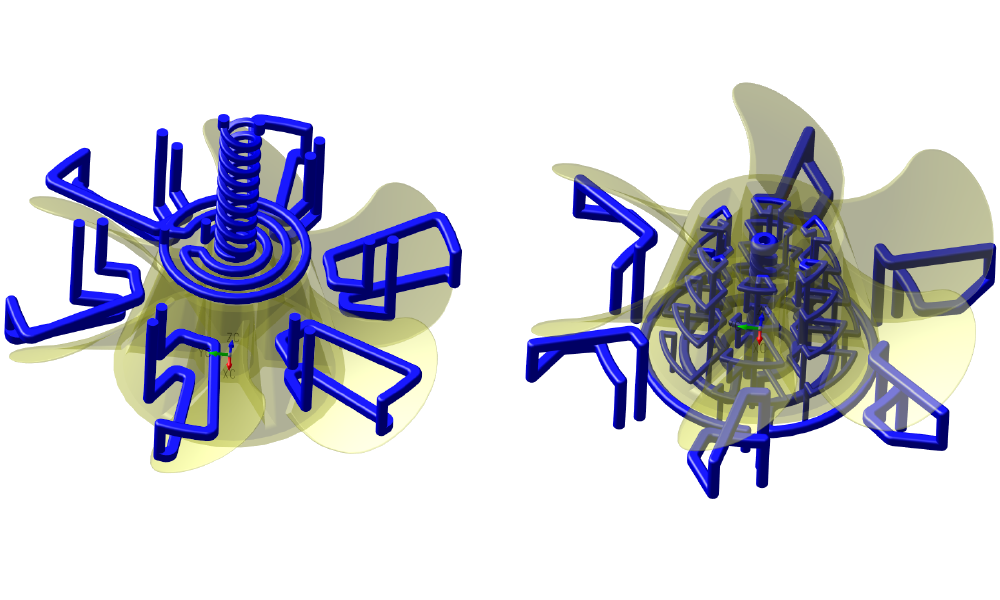

Solution 3 – Conformal Cooling

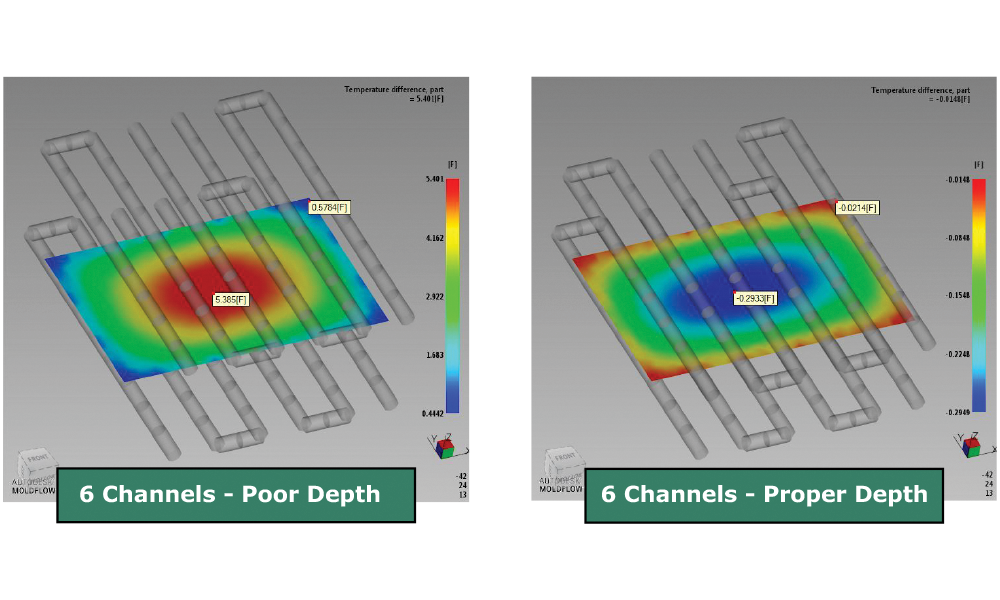

Depth Controls Core/Cavity Differential

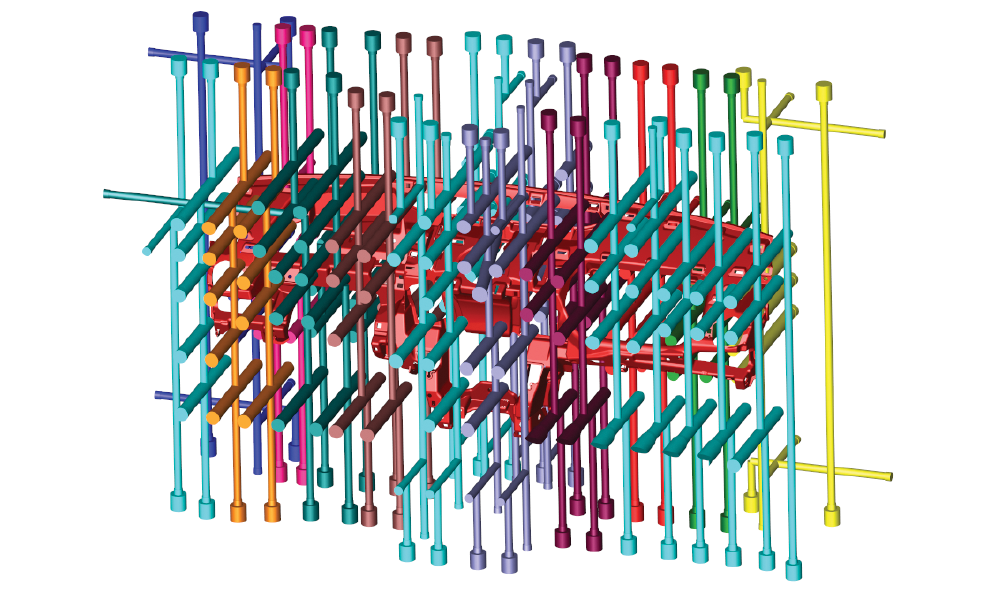

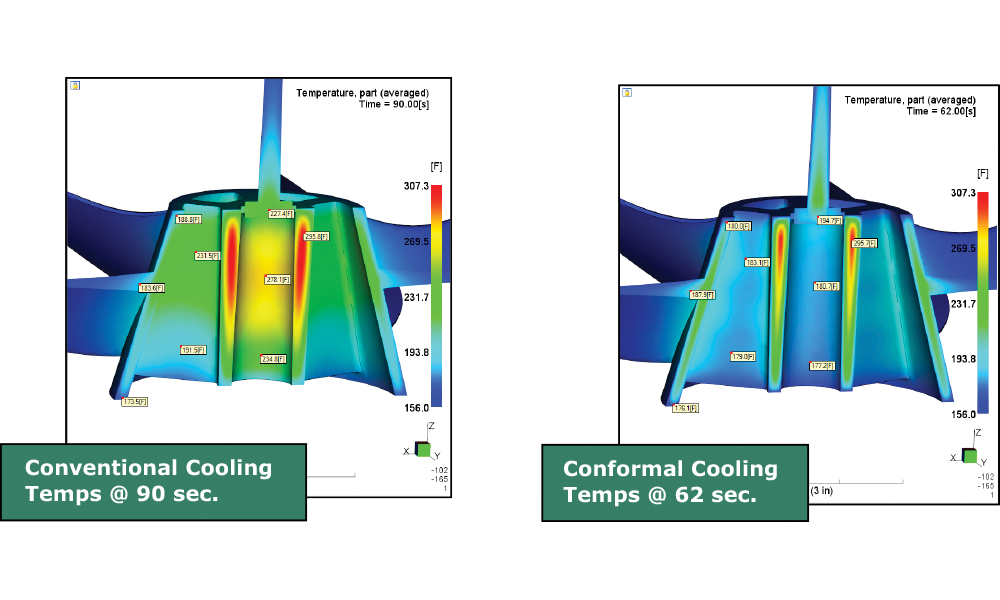

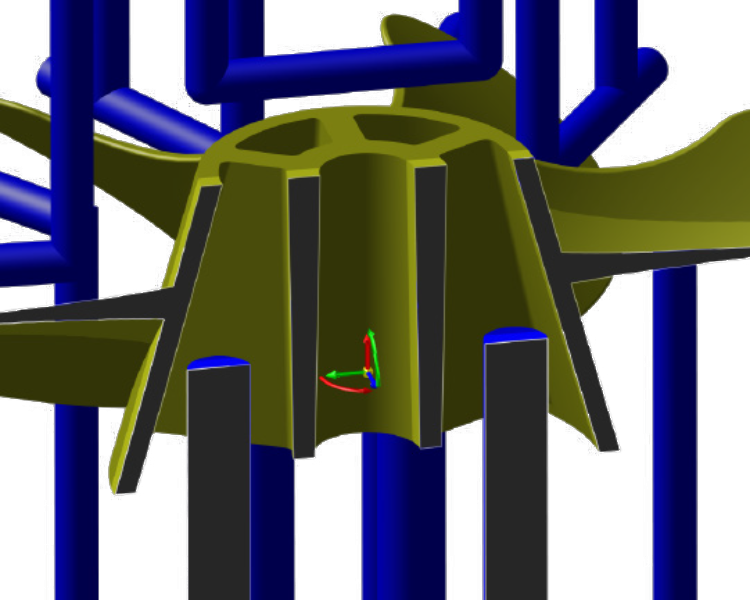

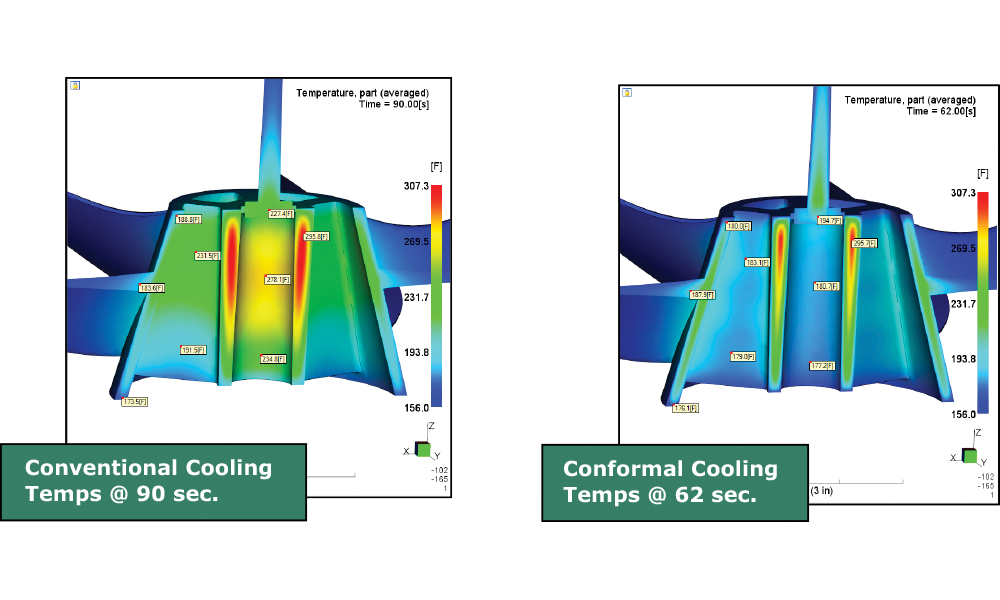

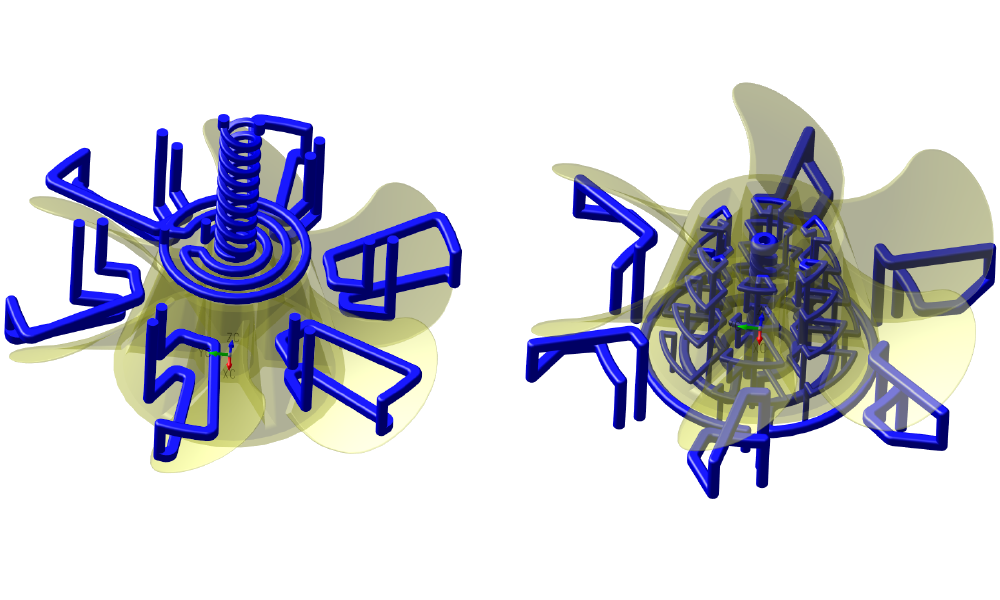

Conventional vs. Conformal

Conventional Cooling Design

-

Can’t get close to surfaces on deep core side pockets

-

Difficult to follow blade contours

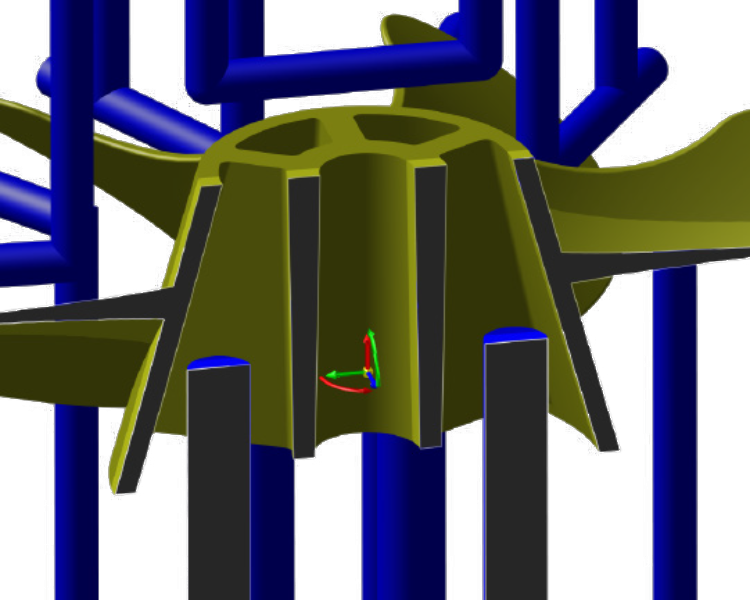

Conformal Cooling Design

Conformal Cooling design courtesy of HTS Intl. Corp.

-

Cooling lines conform to part surface geometry

-

Able to reach deep core areas

-

Added cooling to cold sprue

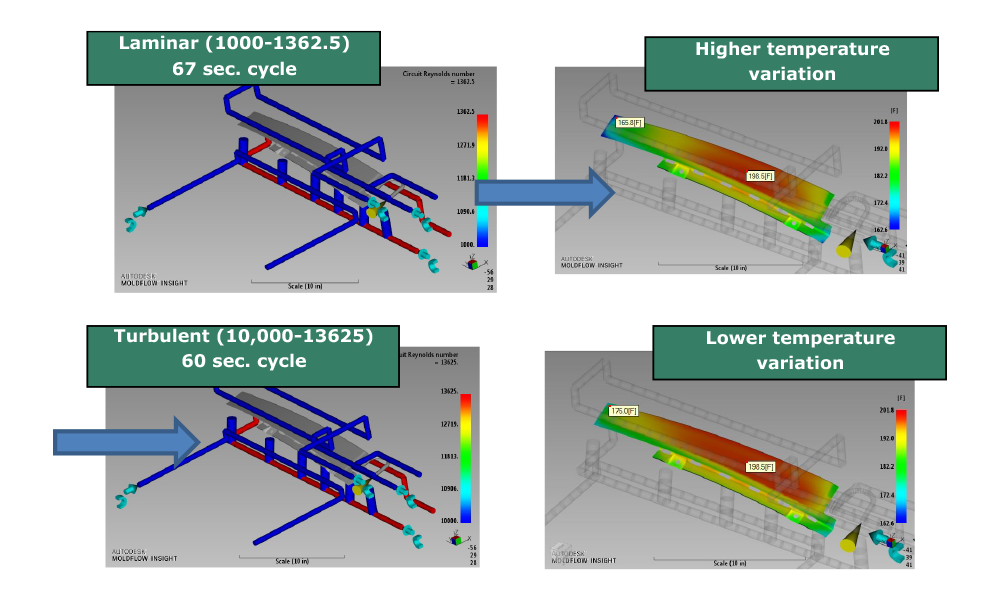

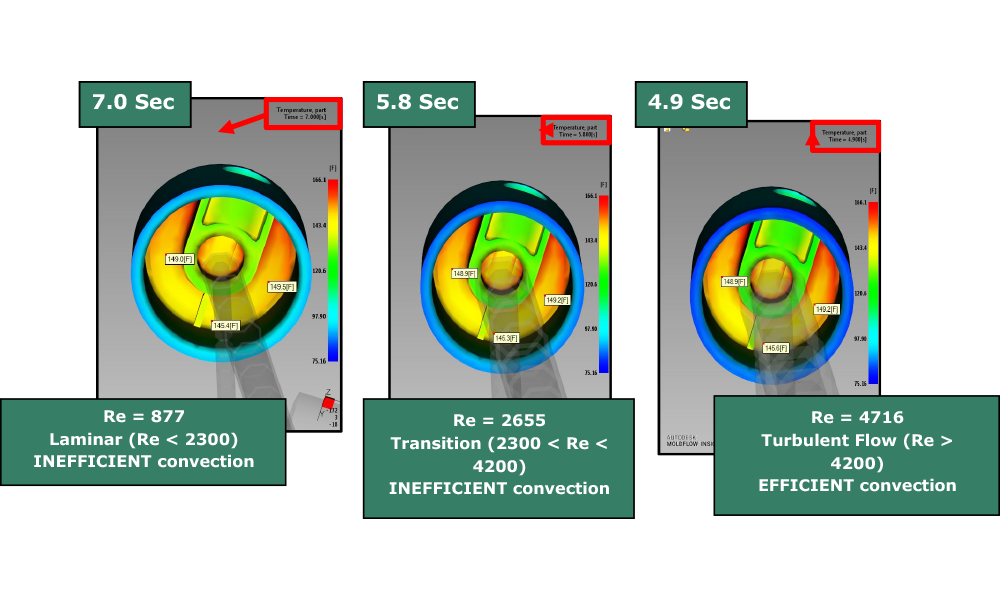

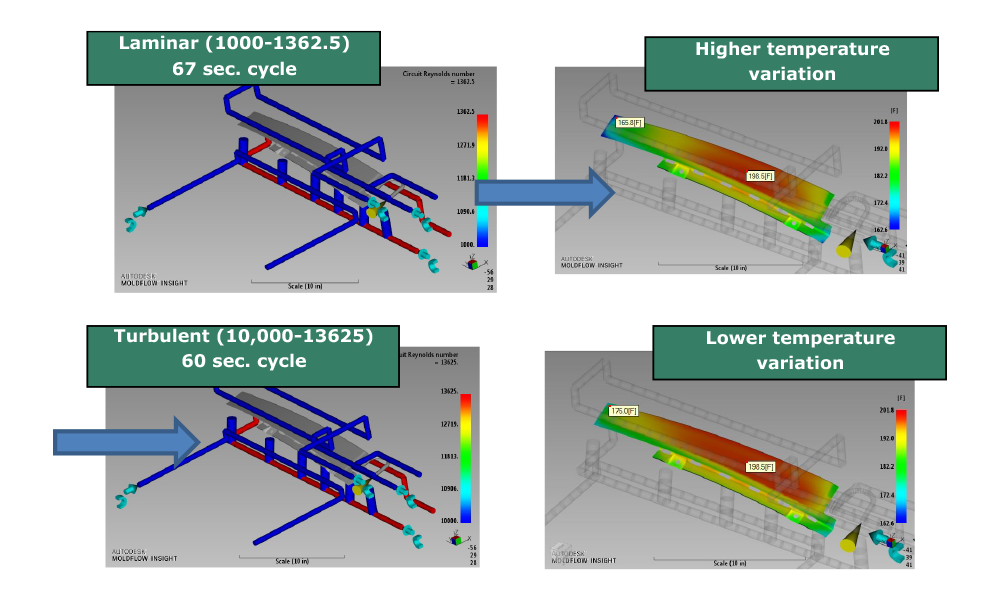

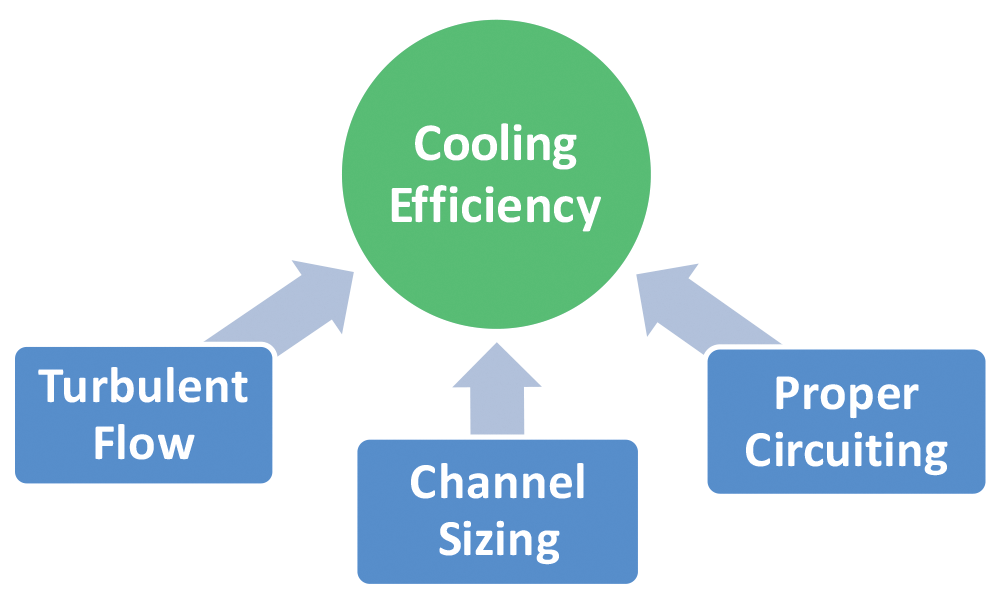

Turbulent Flow Reduces Cooling Time

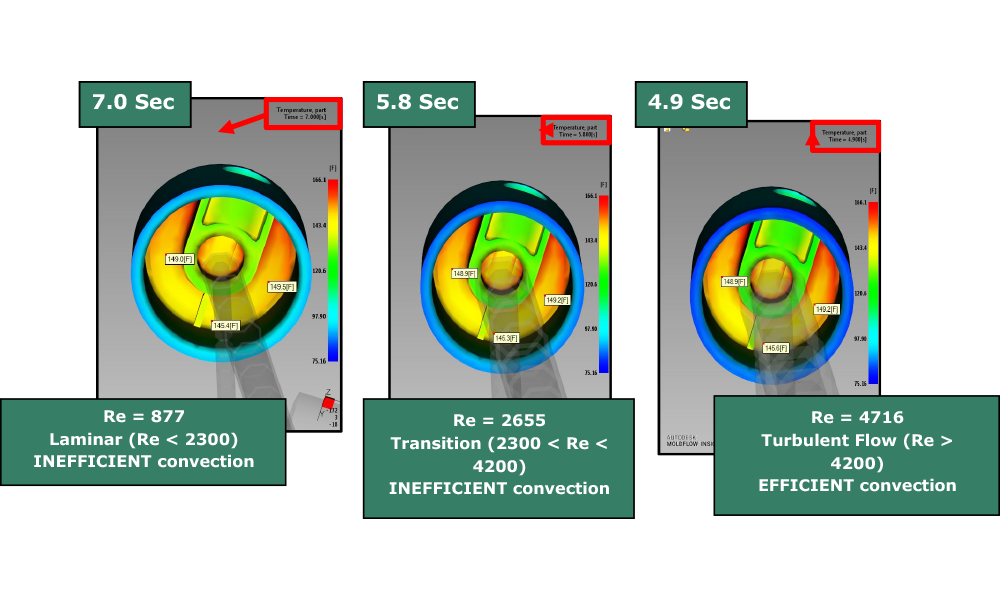

Three Stages of Flow - Reynolds Number

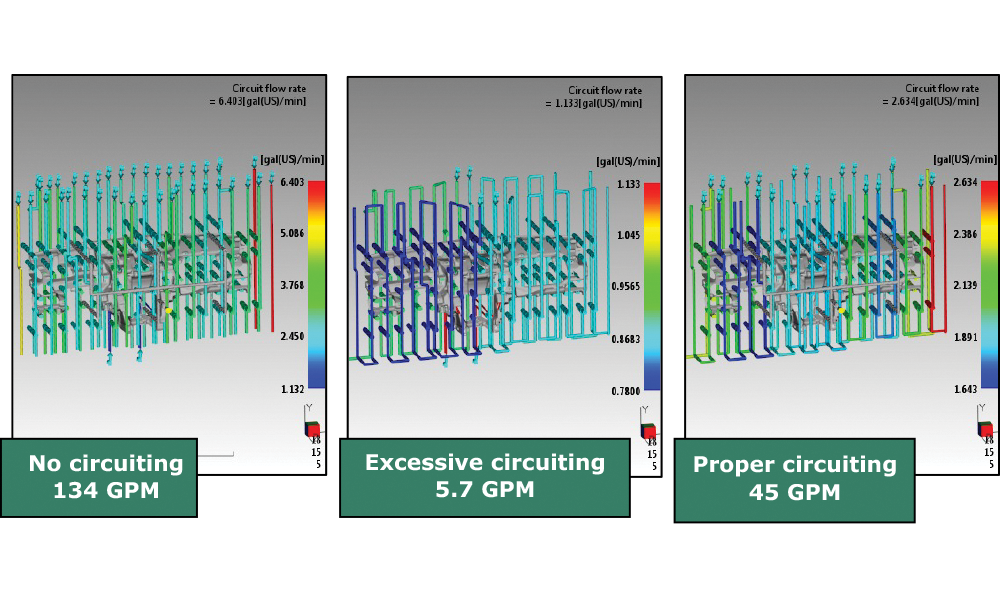

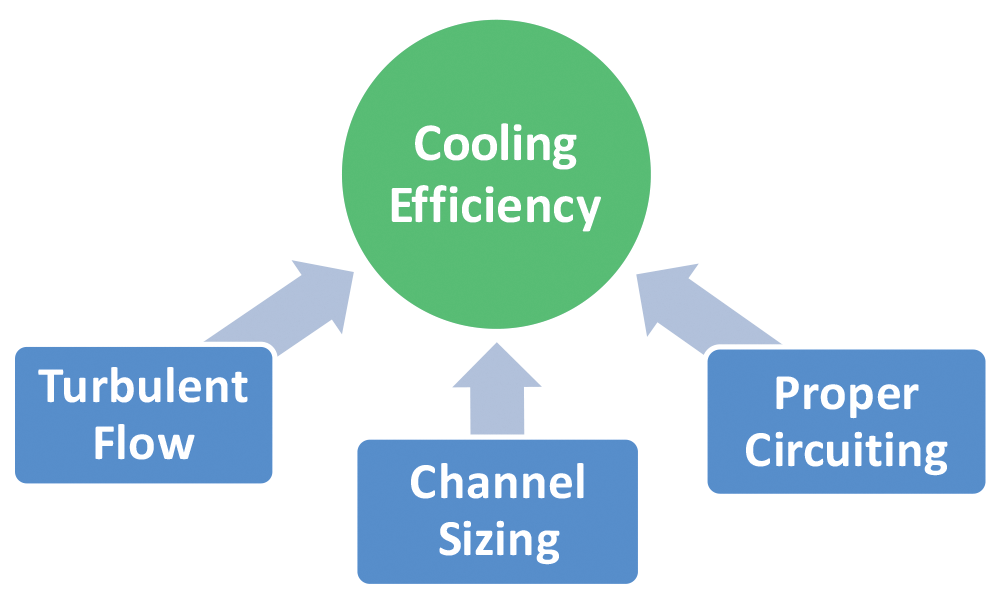

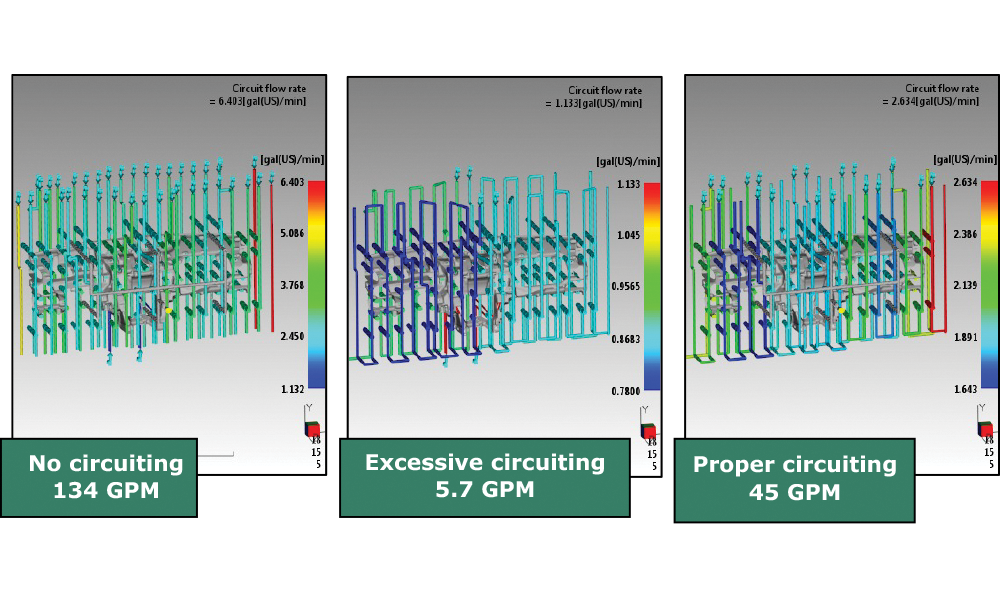

Proper Circuiting = Fewer GPM

So, What's Best for YOU?

- All Cooling Analysis = Opportunity

- Better Parts

-

Increased Profitability

- Better Parts

-

No matter what type of cooling analysis

-

Temperature Uniformity

-

Coolant Flow Efficiency

-

-

Plan ahead to have Moldflow cooling analysis done proactively

-

Have analysis done at the earliest stages of product development

Buy Software, Outsource, or Both?

-

Molders/OEMs

-

Insist on Moldflow analysis – do it yourself or use an outside source

-

Know your GPM (for each line)

-

Do the math – What does X seconds of cycle savings mean?

-

-

Part Designers

-

Avoid difficult-to-cool areas, where possible

-

Use analysis to identify those areas (Moldflow Adviser)

-

-

Moldmakers

-

Be creative and test using analysis

-

Use cooling suggestions from analysis

-

Cooling Analysis – What’s Best For You?

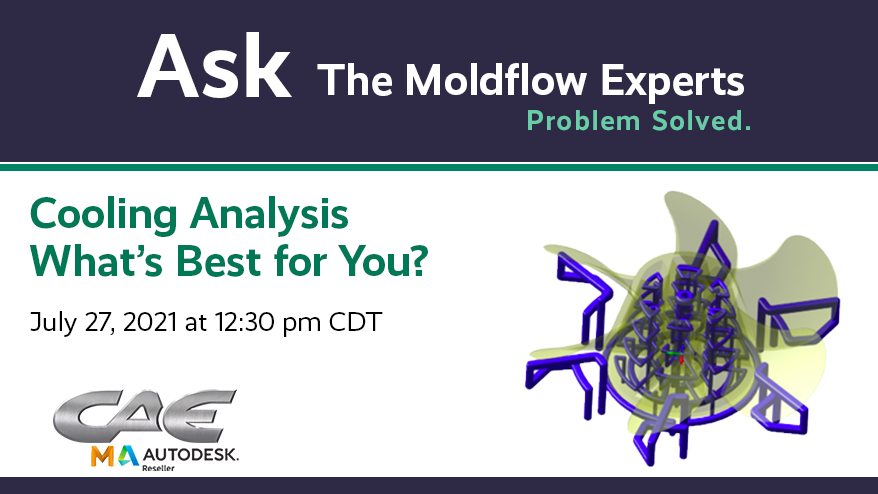

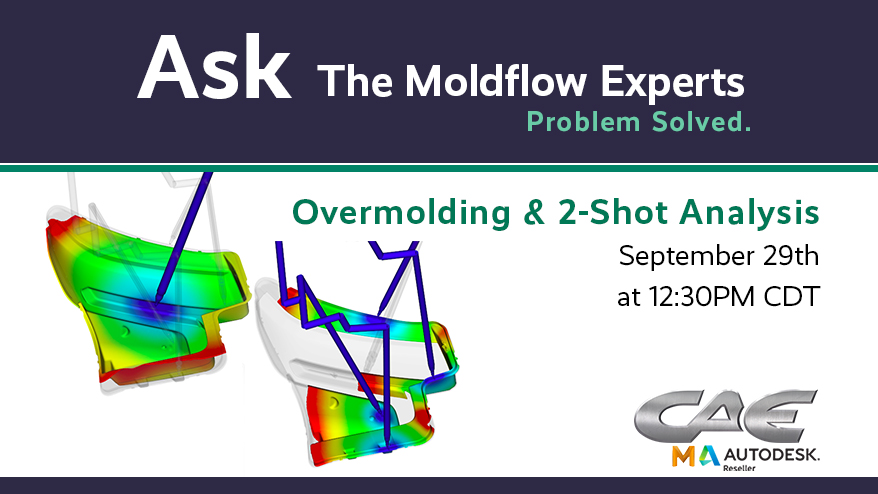

Ask The Moldflow Experts Webinar Topic:

Cooling Analysis – What’s Best For You?

July 27th, 2021 | 12:30 PM CDT

Having a cooling analysis on your mold isn’t hard to justify when you think about how it improves your part quality, molding efficiency and cycle times. But when it comes down to it, how do I know if the type of analysis that’s being run is the right one? Which one is best?

This webinar discussed

How cooling analysis works

What are the different types of cooling analysis that are available?

ATME – Take Away

If you are experiencing cycle time or warpage related problems:

Email Us Today!

Key Cooling Message

The fundamentals don’t change

How do we take advantage of them?

There are different types of Moldflow cooling analysis

Cooling designs shouldn’t be an afterthought

Cooling uniformity and efficiency can be improved PROACTIVELY

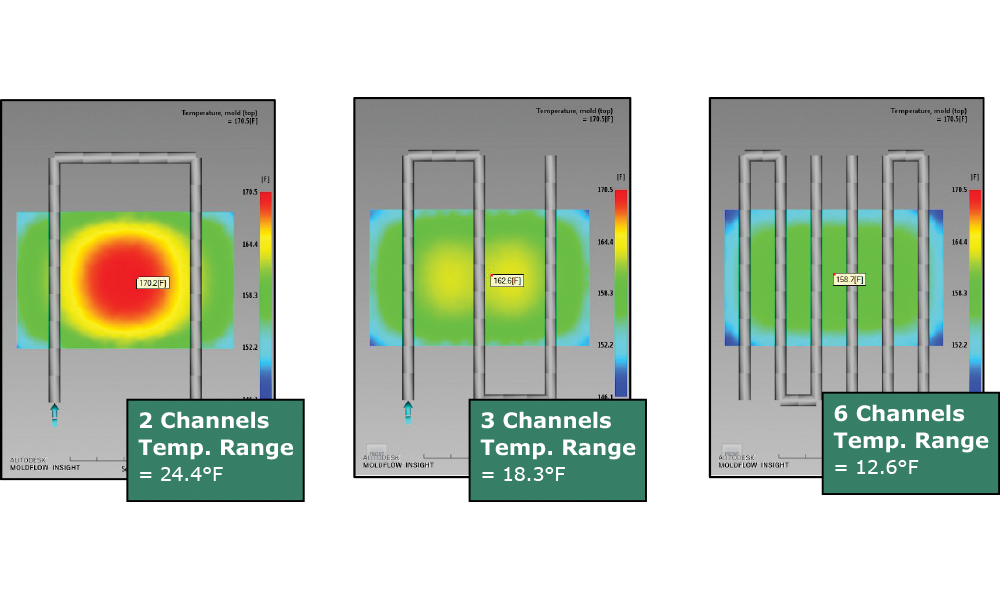

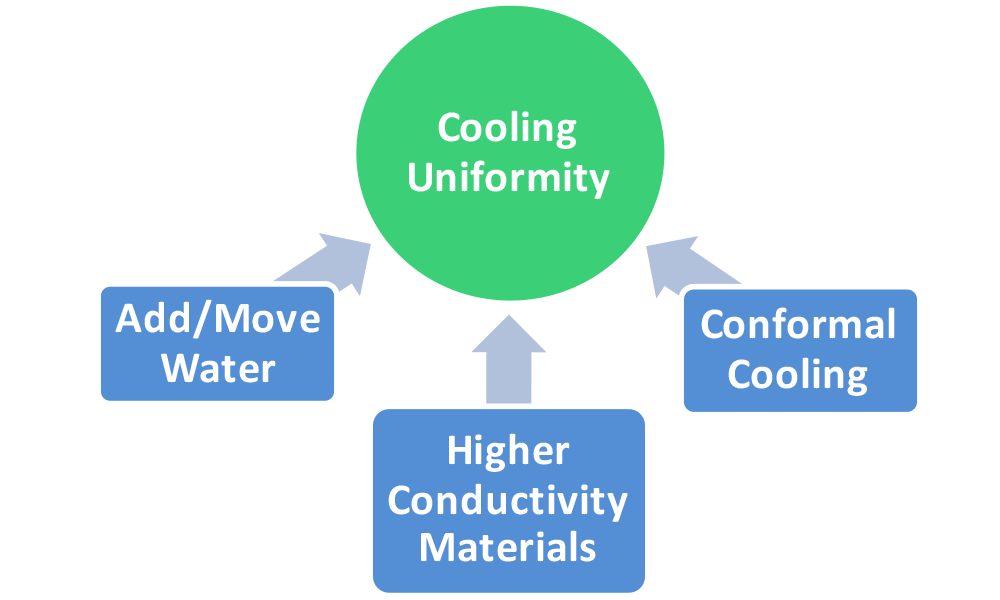

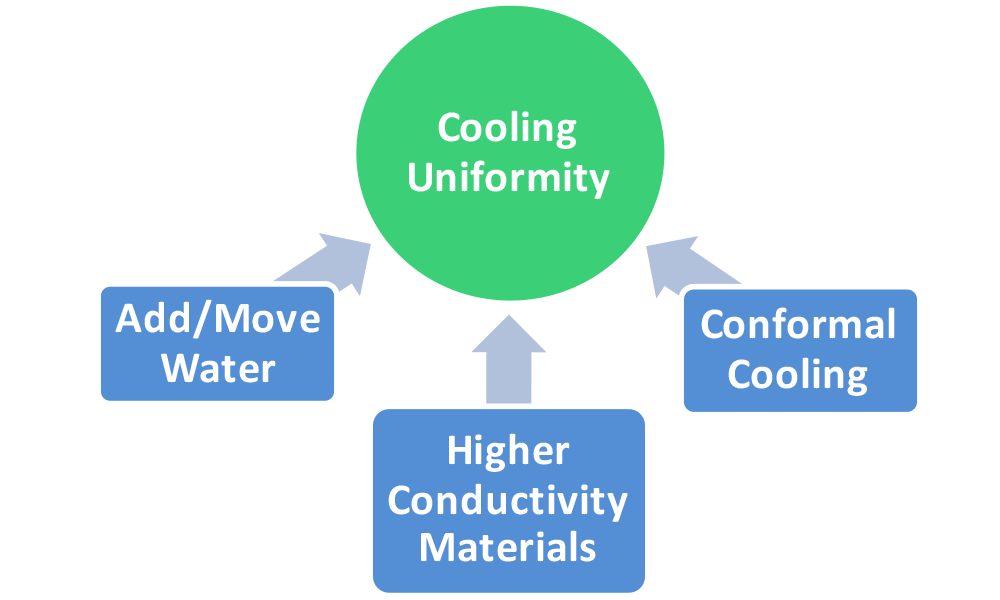

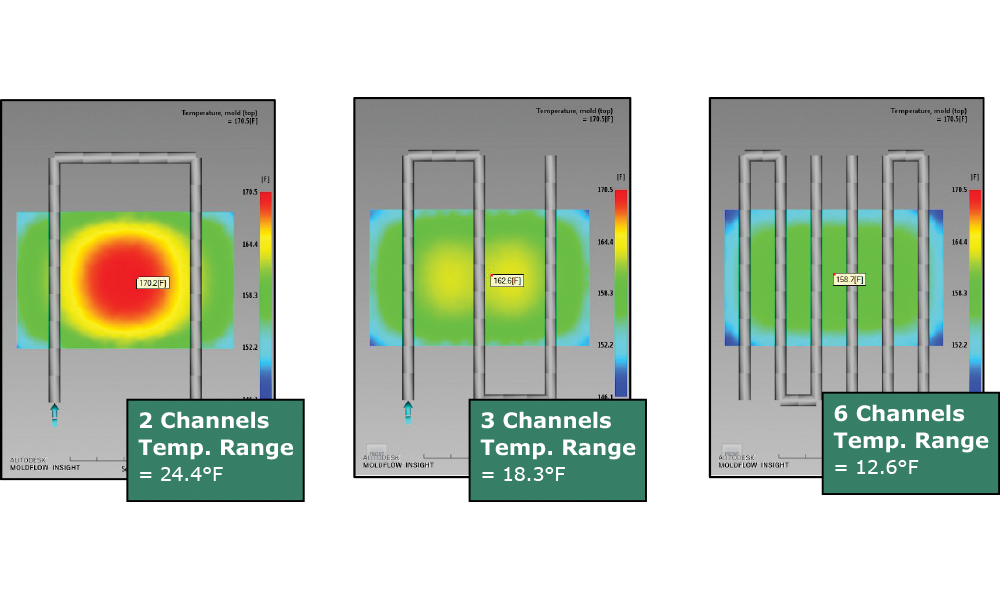

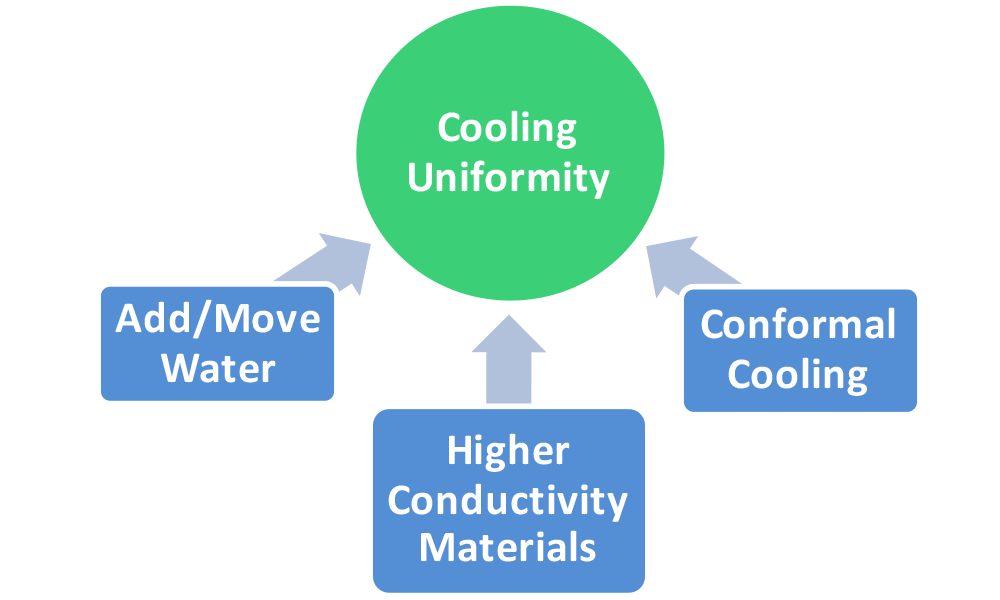

Cooling Uniformity

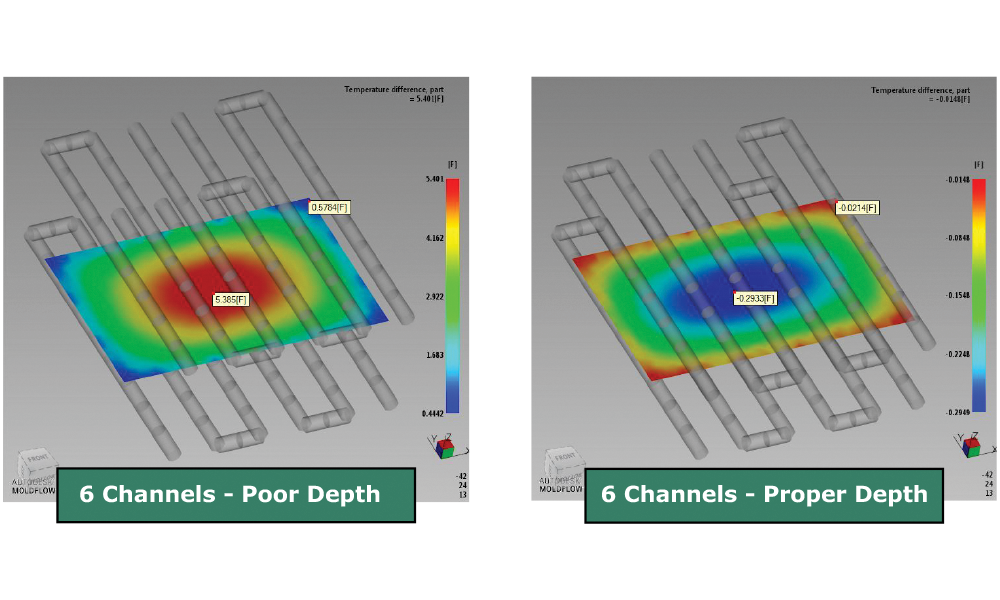

Pitch Controls Surface Uniformity

Improving Cooling Uniformity

Solution 1 – Add/move water

Solution 2 – Higher Conductivity Inserts

Solution 3 – Conformal Cooling

Depth Controls Core/Cavity Differential

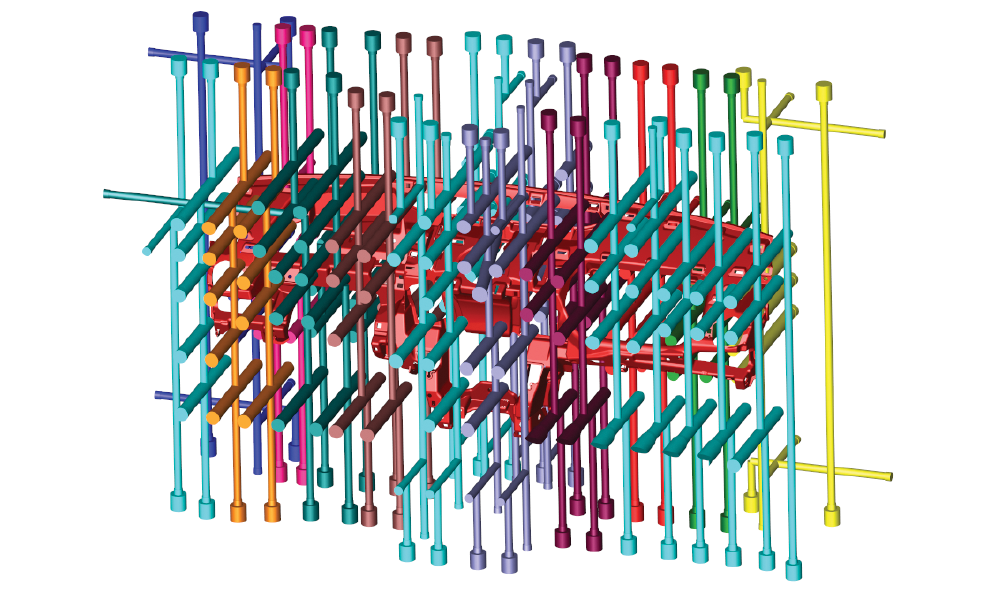

Conventional vs. Conformal

Conventional Cooling Design

Can’t get close to surfaces on deep core side pockets

Difficult to follow blade contours

Conformal Cooling Design

Conformal Cooling design courtesy of HTS Intl. Corp.

Cooling lines conform to part surface geometry

Able to reach deep core areas

Added cooling to cold sprue

Turbulent Flow Reduces Cooling Time

Three Stages of Flow – Reynolds Number

Proper Circuiting = Fewer GPM

So, What’s Best for YOU?

All Cooling Analysis = Opportunity

Better Parts

Increased Profitability

No matter what type of cooling analysis

Temperature Uniformity

Coolant Flow Efficiency

Plan ahead to have Moldflow cooling analysis done proactively

Have analysis done at the earliest stages of product development

Buy Software, Outsource, or Both?

Molders/OEMs

Insist on Moldflow analysis – do it yourself or use an outside source

Know your GPM (for each line)

Do the math – What does X seconds of cycle savings mean?

Part Designers

Avoid difficult-to-cool areas, where possible

Use analysis to identify those areas (Moldflow Adviser)

Moldmakers

Be creative and test using analysis

Use cooling suggestions from analysis