Console Substrate Reinforcement

Objectives

CAE Services was contracted to determine the excessive inward warpage on the side railing of the console substrate reinforcement part in a baseline correlation study. Additional tasks were to investigate potential process, part design, or mold design improvements to reduce or eliminate the warpage.

Preliminary Results

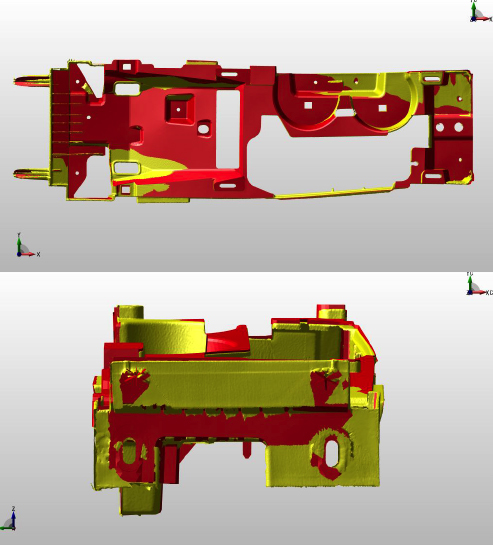

- Results showed good correlation with laser-scanned molded samples;

- Primary cause of warpage was shrinkage variation due to fiber orientation shrinkage in the side railing;

- Shrinkage variation due to packing was also a factor;

CAE Recommendations

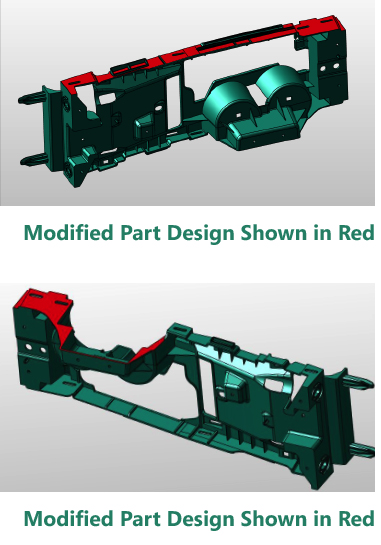

The following recommendations were made by the CAE engineering team to establish a baseline correlation between simulation and the existing molding setup while investigating improvements:

- Increase wall stock in the side railing and cupholder areas to 3.0 mm nominal;

- Increase packing time to reduce shrinkage variations due to packing;

- Shut off one of the hot drops in order to promote more uni-directional flow and fiber orientation

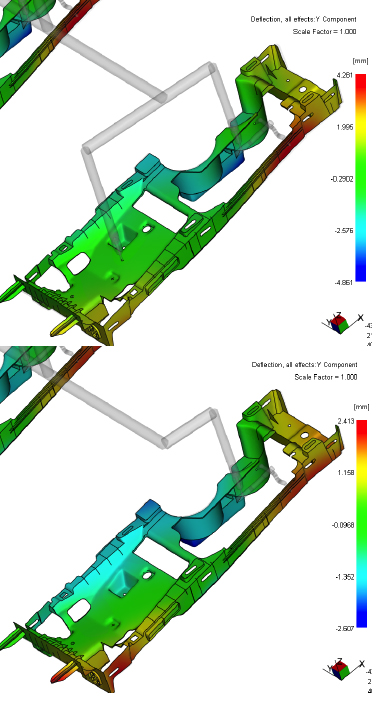

Final Results

Warpage was reduced by 1.8 mm in the side railing and by 2.2 mm in the cupholder area.

Summary

CAE Services’ engineers were able to meet the objectives put forth by the client. The engineering team established a baseline correlation between the simulation and the existing mold. It was recommended that the wall stock be increased in the side railing and the cup holder area to 3.0mm significantly reducing the warpage. Additional changes suggested were to increasing packing time which resulted in lower shrinkage variations. Shutting off one drop and creating a single injection point allowed a more unidirectional flow and aligned fiber orientation. Ultimately, CAE Services was able to provide a solution that benefited this project in several ways.