Consulting Levels

Bronze LCC

Not concerned with cycle times or part warpage?

Bronze Plus

Are excessive mold samplings eroding your profits?

Silver

Optimize your part design

Gold

Require warpage optimization?

Platinum Level

Your part design is frozen

Titanium Level

Specialty services

Consulting | Software | Training:

Improved Part Quality

Faster Cycle Times

Larger Processing Window

Less "Fire Fighting"

More Profit

Bronze LCC

Not concerned with cycle times or part warpage?Affordable low-cost Moldflow simulation. Perfect for prototype tooling sources and product designers who require gate sizing, weld line locations, and clamp tonnage results within days, not weeks! Simply send part data, material info and let our LCC group do the rest! Save time & money with our affordable low-cost simulation approach to Moldflow analysis.

Bronze Plus

Are excessive mold samplings eroding your profits?Truth be told not all part designs have stringent warpage tolerance objectives or require warpage optimization, a “Just to be Sure” analysis of the part & mold design is often sufficient. So if your part design is “Frozen” and an “Expert Certified” analyst is required to confirm gate size, drop locations, bore diameter sizing, SVG, clamp tonnage, as well as evaluating Cooling & Warpage results to minimize risk then consider our Bronze Plus Level.

Silver

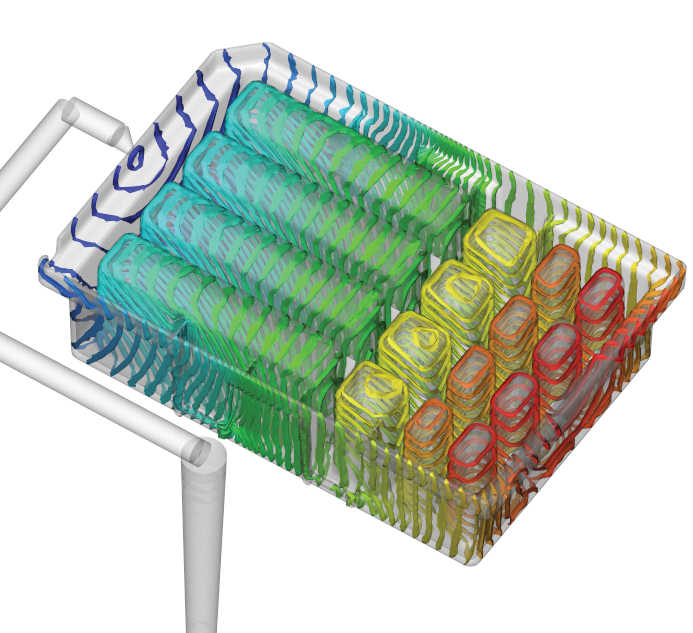

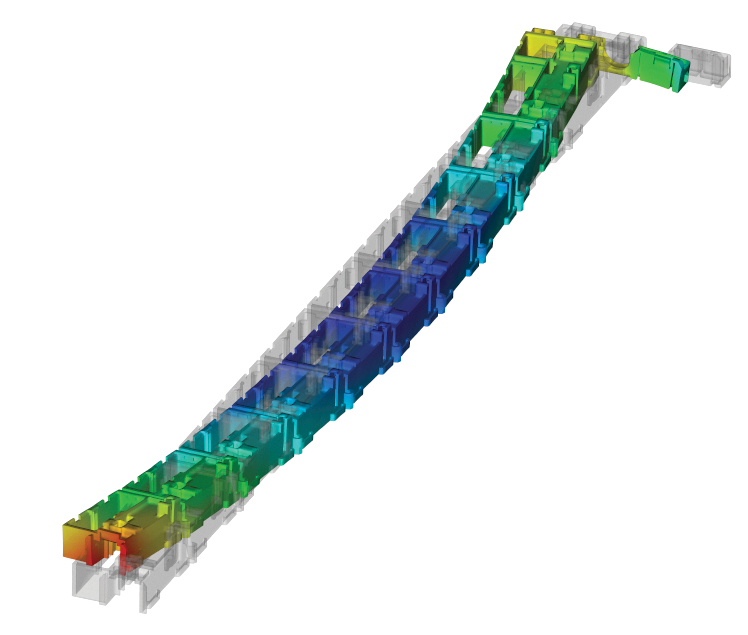

Optimize your part designSave time & money by evaluating your part design prior to sourcing to your mold builder. Our staff will recommend part design changes to optimize your processing window in order to eliminate surprises during mold sampling. Silver level results include; gate sizing, drop locations, bore diameter sizing, SVG timing sequencing, identifying weld line locations, calculate shear rate, volumetric shrinkage, clamp tonnage, and Isothermal warpage trends. Unlimited gating iterations are provided @ no additional cost. Cooling and warpage analysis is available at the Gold Level.

Gold

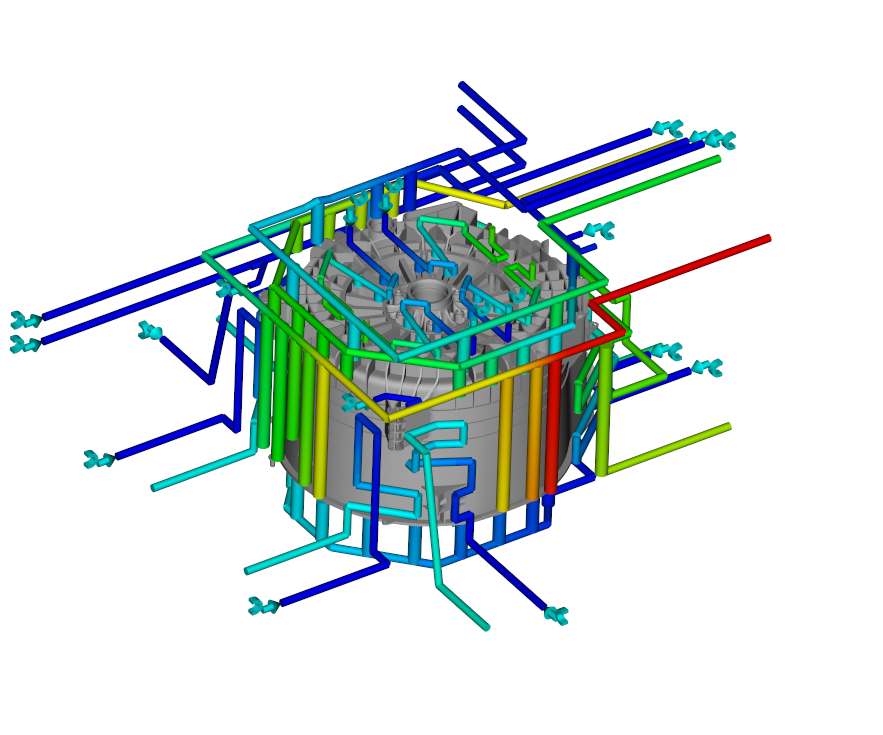

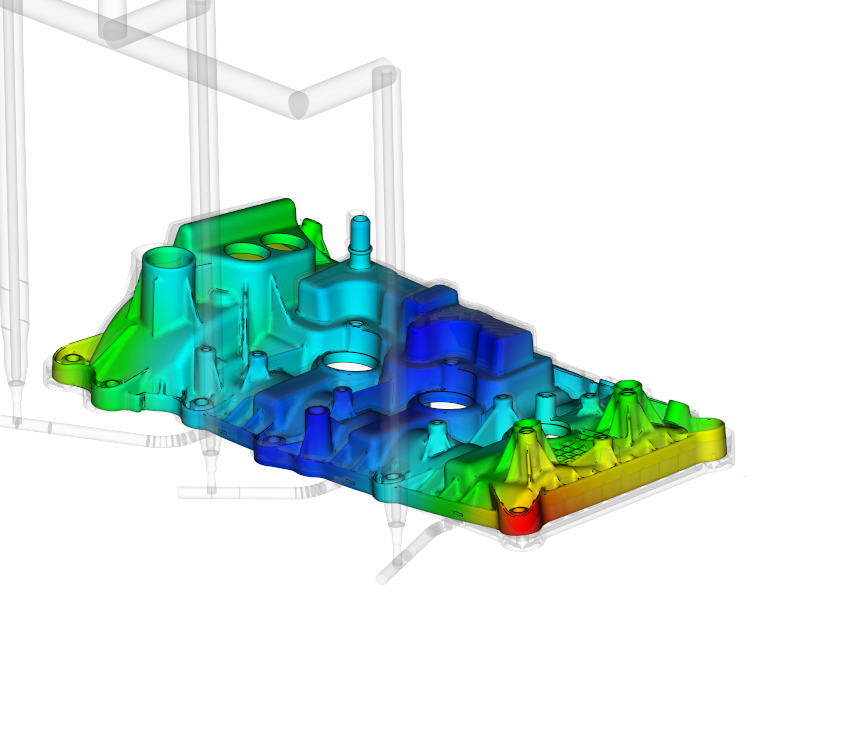

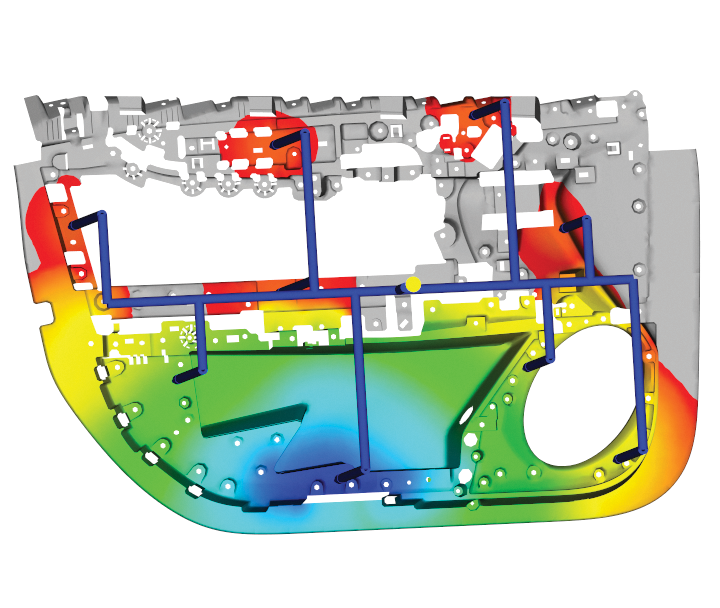

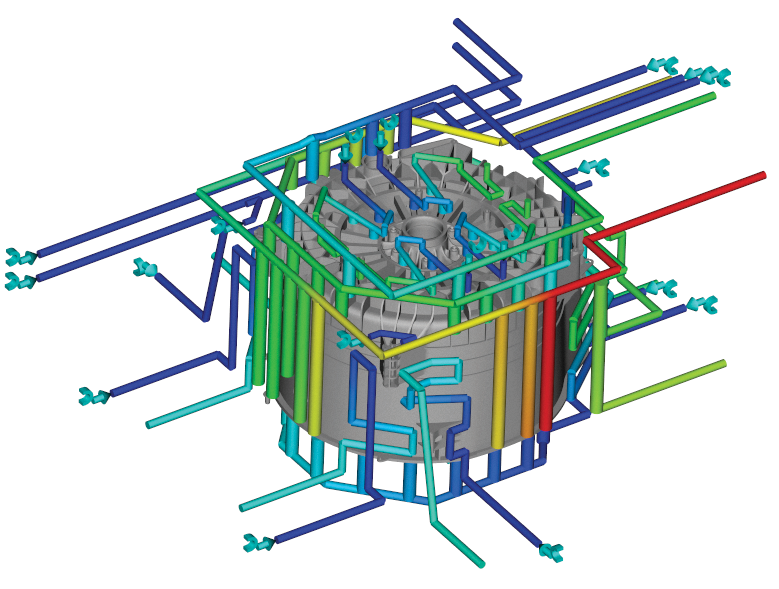

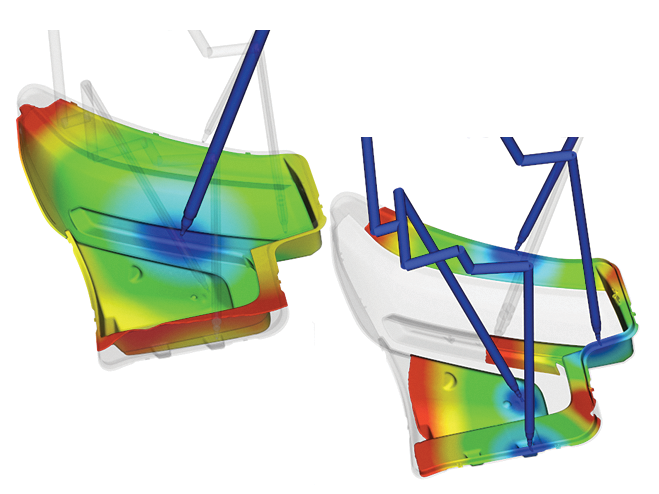

Require warpage optimization?Our solution based Gold level provides a thorough evaluation of the material, part design, gating options, hot or cold runner applications, mold design for cooling uniformity, as well as determining the primary cause of warpage. Our Expert Certified staff will then recommend part or tool design changes to minimize warpage and improve the processing window. Our Gold level is an absolute “must have” if warpage is a concern.

Platinum Level

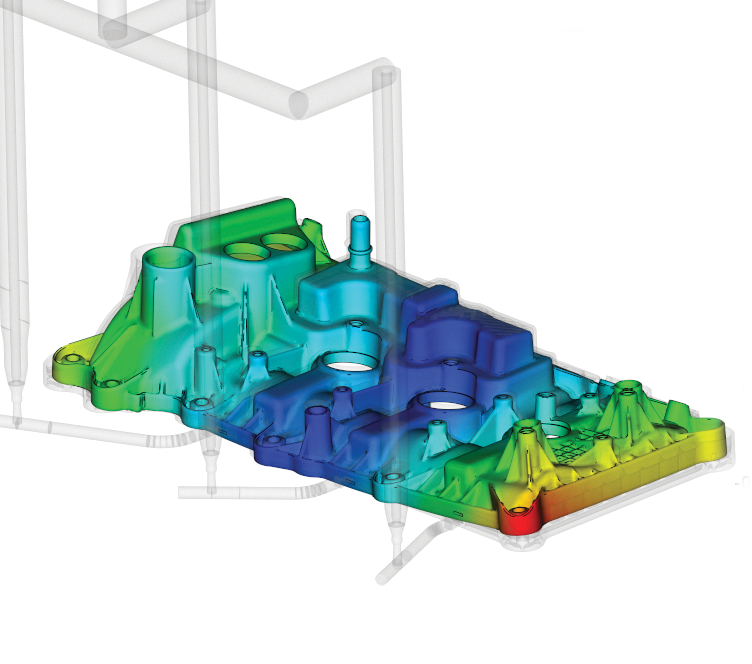

Your part design is frozenCan’t change the material or gate location? Now what? Developed for “Part to Print” or tight tolerance applications, and for processors who want to reduce the costs & timing associated with numerous “tuning loops.” Our Platinum level is a method of biasing the mold cavity in the opposite direction (windage) to the measured warpage in order to have the part warp into its intended shape. If you have experienced “part to print” issues in the past and want to save time and money in the future, then consider our Platinum process.

Titanium Level

Specialty servicesi.e. Gas Assist, Injection/Compression, Encapsulation, Co-Injection, 2/3 Shot and MuCell. Have a challenging application or require an experienced team of Expert Certified Moldflow analysts? Call us @ 630.761.9898.

Download Consulting Levels PDF

Click To Download Now

Consulting | Software | Training:

Improved Part QualityFaster Cycle TimesLarger Processing WindowLess “Fire Fighting”More Profit

Company*Name*

First

Last

Email*

Phone*Comments*CAPTCHA

jQuery(document).ready(function($){gformInitSpinner( 2, ‘https://caeservices.com/wp-content/plugins/gravityforms/images/spinner.gif’ );jQuery(‘#gform_ajax_frame_2’).on(‘load’,function(){var contents = jQuery(this).contents().find(‘*’).html();var is_postback = contents.indexOf(‘GF_AJAX_POSTBACK’) >= 0;if(!is_postback){return;}var form_content = jQuery(this).contents().find(‘#gform_wrapper_2’);var is_confirmation = jQuery(this).contents().find(‘#gform_confirmation_wrapper_2’).length > 0;var is_redirect = contents.indexOf(‘gformRedirect(){‘) >= 0;var is_form = form_content.length > 0 && ! is_redirect && ! is_confirmation;var mt = parseInt(jQuery(‘html’).css(‘margin-top’), 10) + parseInt(jQuery(‘body’).css(‘margin-top’), 10) + 100;if(is_form){jQuery(‘#gform_wrapper_2’).html(form_content.html());if(form_content.hasClass(‘gform_validation_error’)){jQuery(‘#gform_wrapper_2’).addClass(‘gform_validation_error’);} else {jQuery(‘#gform_wrapper_2’).removeClass(‘gform_validation_error’);}setTimeout( function() { /* delay the scroll by 50 milliseconds to fix a bug in chrome */ jQuery(document).scrollTop(jQuery(‘#gform_wrapper_2’).offset().top – mt); }, 50 );if(window[‘gformInitDatepicker’]) {gformInitDatepicker();}if(window[‘gformInitPriceFields’]) {gformInitPriceFields();}var current_page = jQuery(‘#gform_source_page_number_2’).val();gformInitSpinner( 2, ‘https://caeservices.com/wp-content/plugins/gravityforms/images/spinner.gif’ );jQuery(document).trigger(‘gform_page_loaded’, [2, current_page]);window[‘gf_submitting_2’] = false;}else if(!is_redirect){var confirmation_content = jQuery(this).contents().find(‘.GF_AJAX_POSTBACK’).html();if(!confirmation_content){confirmation_content = contents;}setTimeout(function(){jQuery(‘#gform_wrapper_2’).replaceWith(confirmation_content);jQuery(document).scrollTop(jQuery(‘#gf_2’).offset().top – mt);jQuery(document).trigger(‘gform_confirmation_loaded’, [2]);window[‘gf_submitting_2’] = false;}, 50);}else{jQuery(‘#gform_2’).append(contents);if(window[‘gformRedirect’]) {gformRedirect();}}jQuery(document).trigger(‘gform_post_render’, [2, current_page]);} );} ); jQuery(document).bind(‘gform_post_render’, function(event, formId, currentPage){if(formId == 2) {if(typeof Placeholders != ‘undefined’){

Placeholders.enable();

}jQuery(‘#input_2_4’).mask(‘(999) 999-9999’).bind(‘keypress’, function(e){if(e.which == 13){jQuery(this).blur();} } );} } );jQuery(document).bind(‘gform_post_conditional_logic’, function(event, formId, fields, isInit){} ); jQuery(document).ready(function(){jQuery(document).trigger(‘gform_post_render’, [2, 1]) } );