Designing an injection molded part?

Injection molding is a complex process! Vital to the success of any project is the ability to evaluate & identify part design and warpage related issues prior to "cutting steel." What happens if the part fails in application, warps, or if the quoted cycle time is not achievable? Who pays the price?

Since 1988, CAE Services has been providing Moldflow services for OEMs, product designers, mold builders, and injection molders. Today, we offer a turnkey solution approach; Part feasibility, FEA, Moldflow analysis, sampling support, and analysis implementation.

If you're looking to improve product to market cycles and need to "Get it Right the First Time," call us today and join our team of satisfied clients!

Moldflow Analysis Services

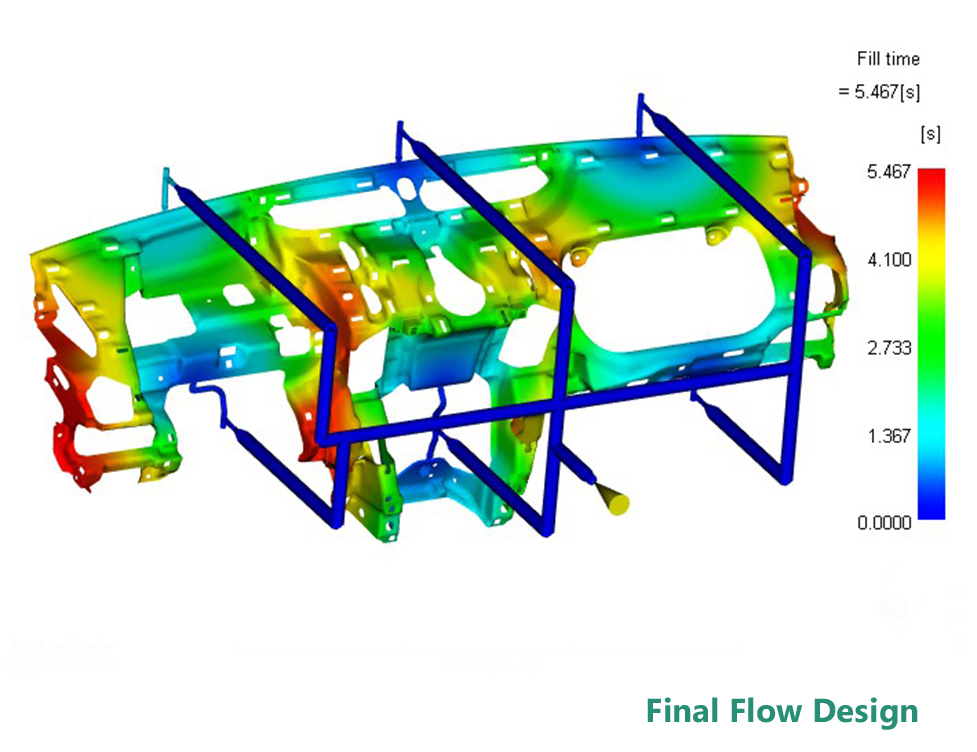

Filling

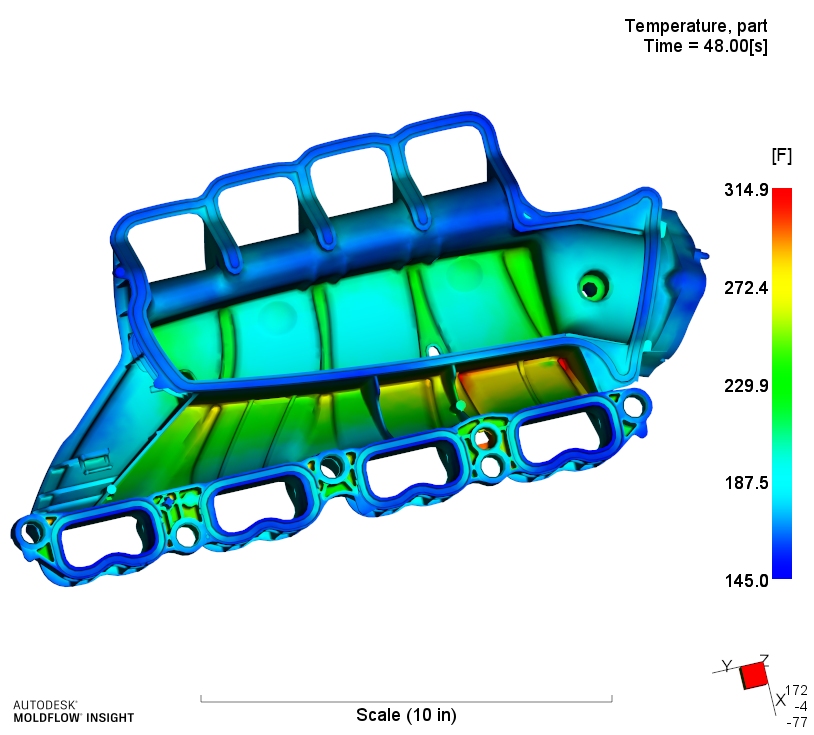

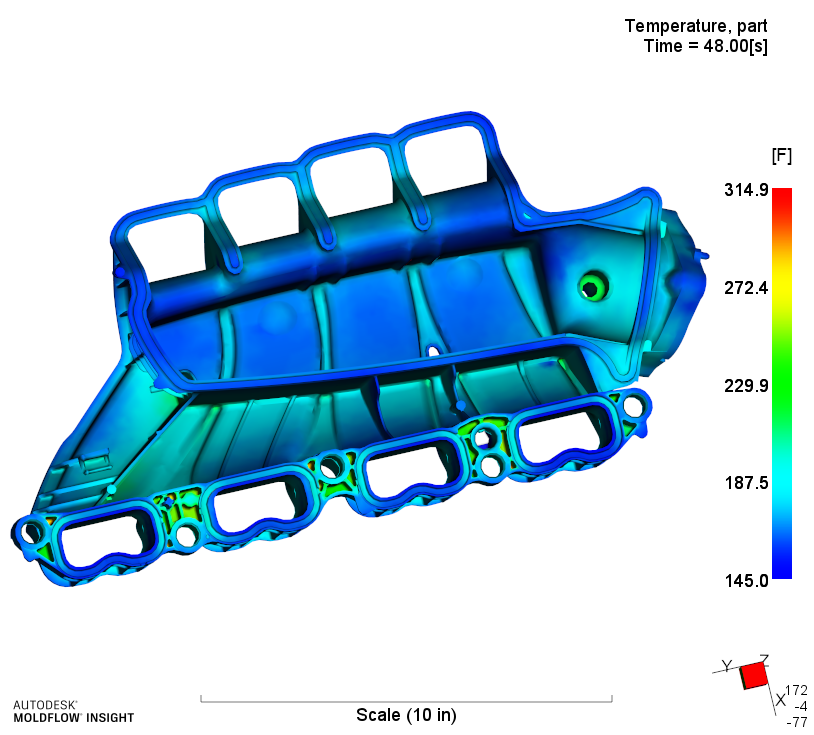

Cooling

Hot Spots - Without Moldmax

Hot Spots Eliminated - With Moldmax

Buckling Problem Identified

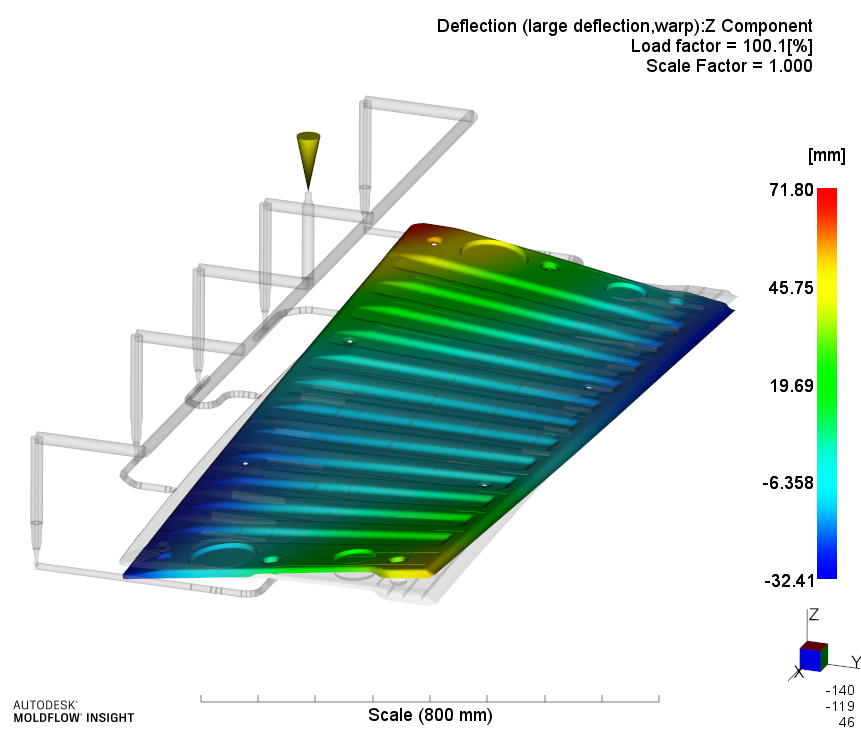

Warpage

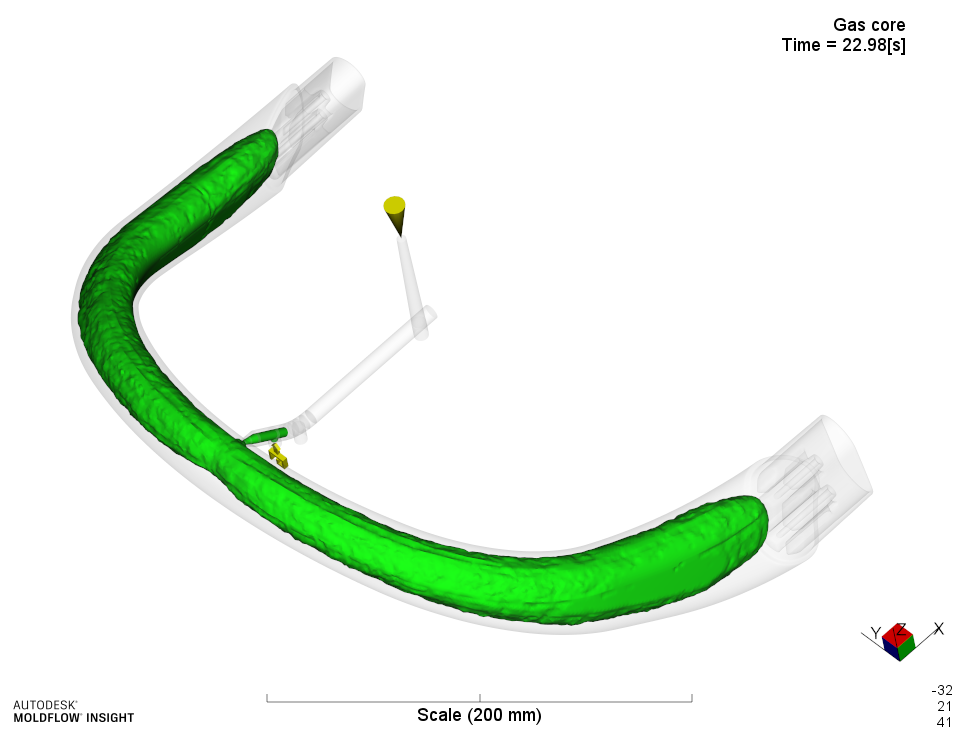

Gas Assist

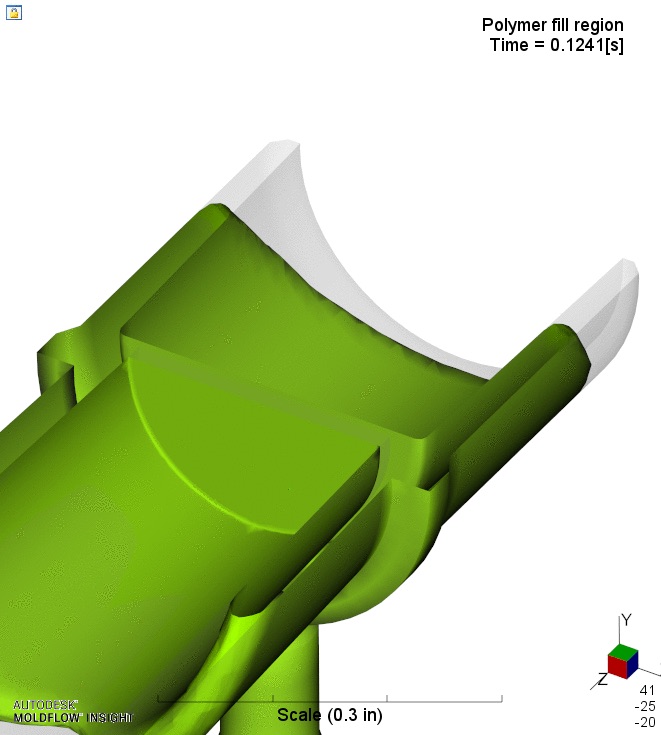

Co-Injection

Injection Compression

Compression Used To Create Thin Membrane

2-Shot

2-shot analysis requires balanced gate locations that avoid prominent knit lines. Air traps for the 2nd shot should be pushed to the parting line instead of up against the 1st shot material.

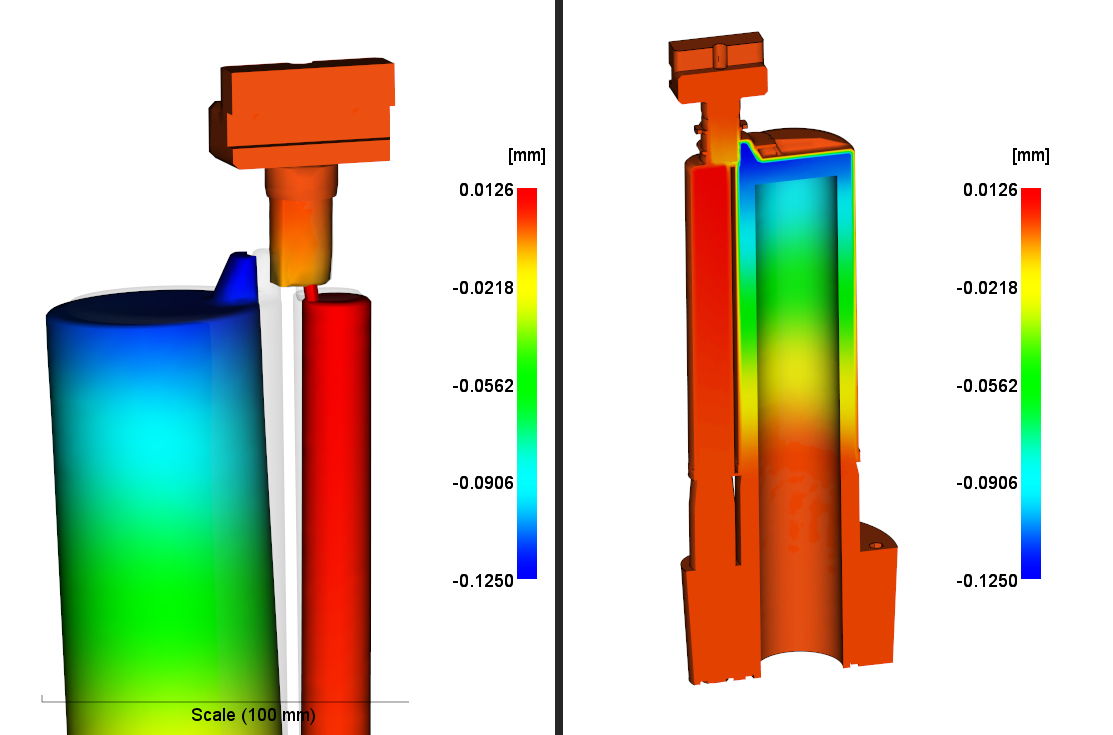

Core Shift

Core Shift Displacement

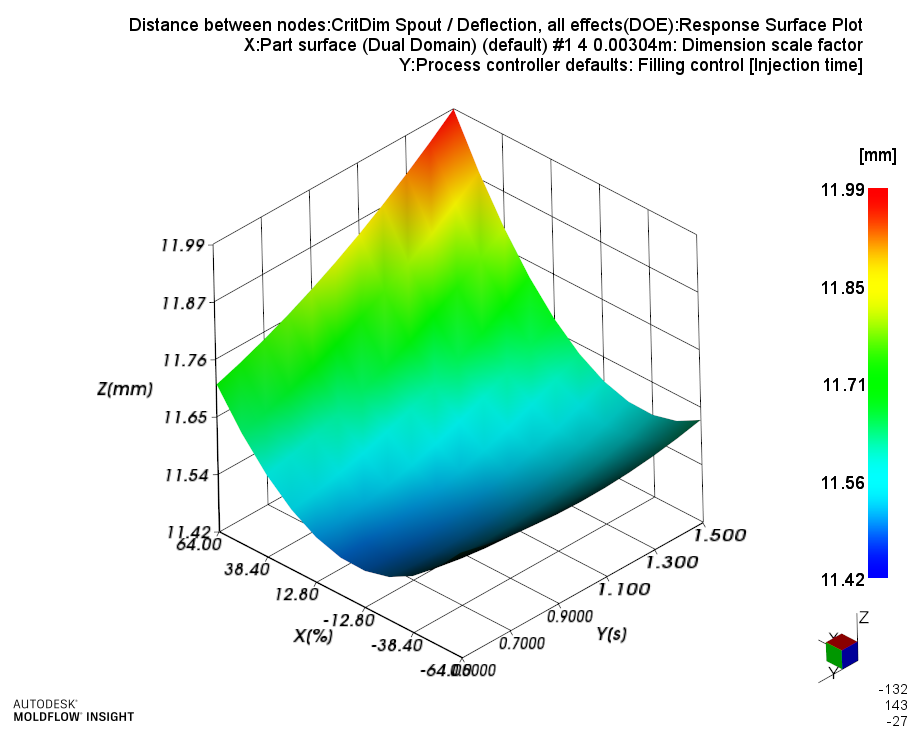

DOE

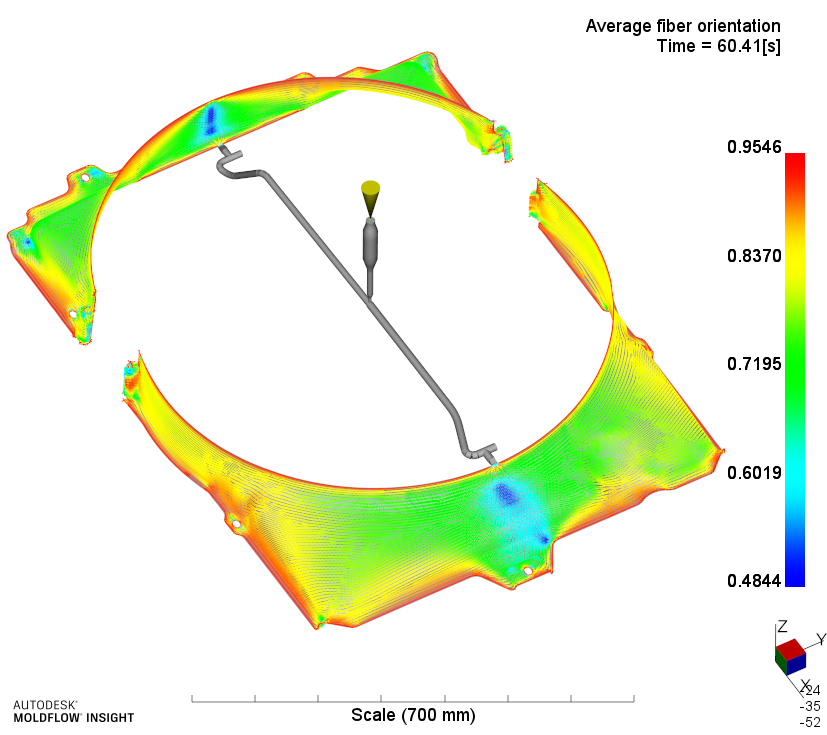

Fiber Orientation

Balanced Compression Filling Pattern

Compression

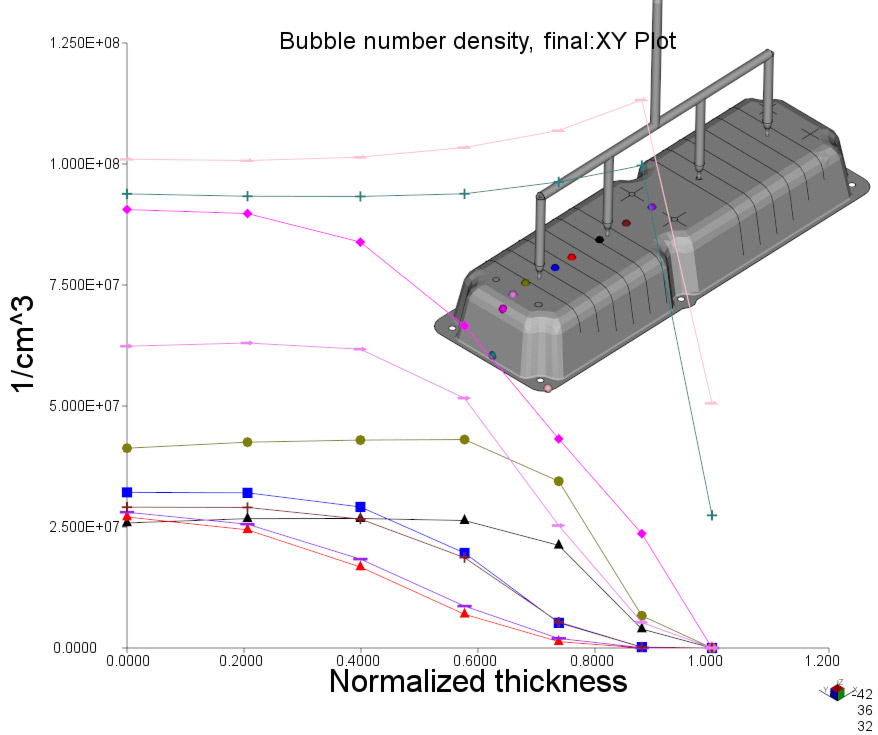

MuCell

Bubble Number Density

Volumetric Shrinkage

Packing

Consulting | Software | Training:

Improved Part Quality

Faster Cycle Times

Larger Processing Window

Less "Fire Fighting"

More Profit