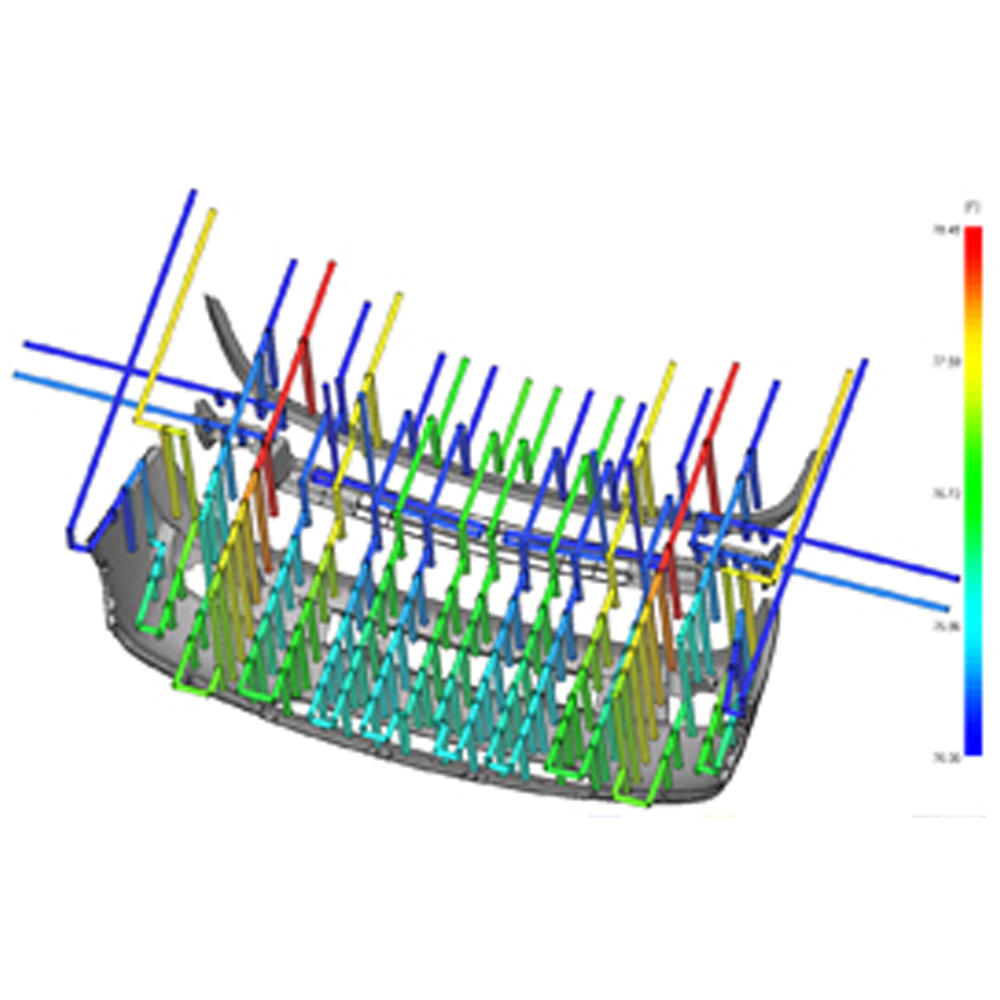

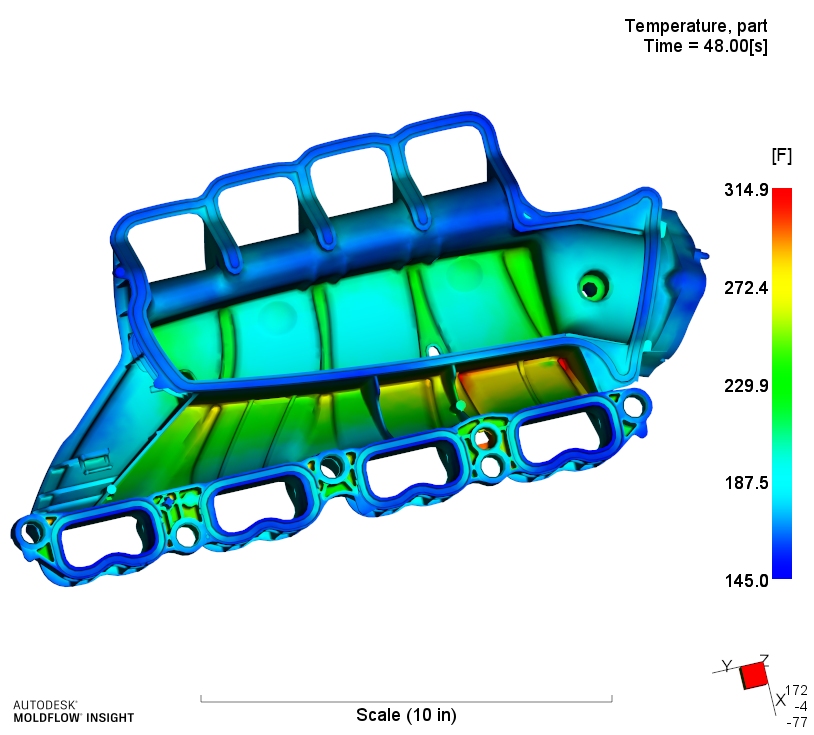

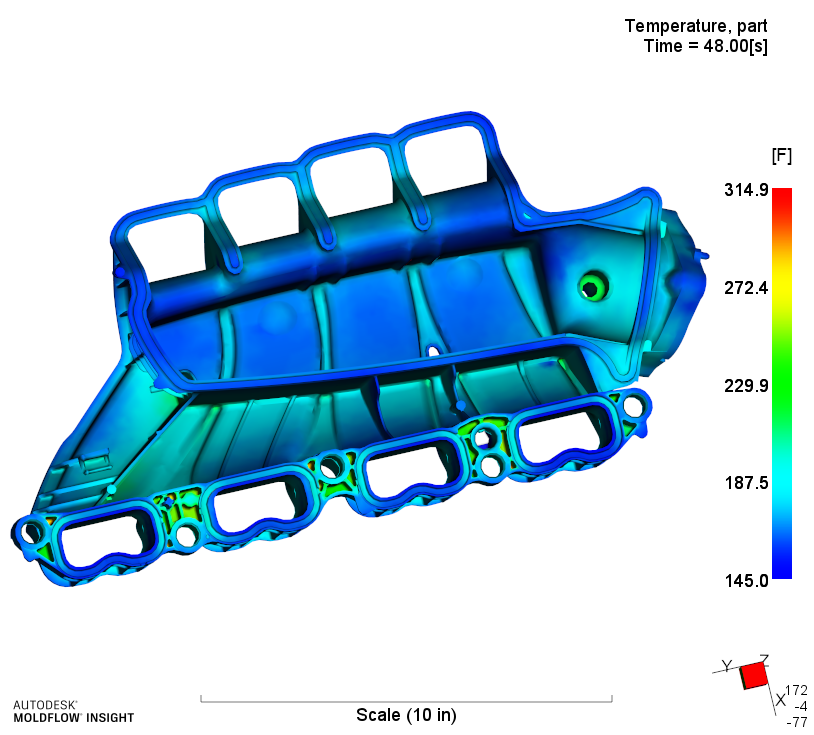

Cooling Analysis

Ensuring your part cools efficiently is a major part of keeping your molding process optimized, keeping costs under control, and maintaining profitable cycle times. Conducting a cooling analysis before you start your mold is key. Our cooling analysis can accurately simulate any number of cooling designs to achieve the uniform part cooling you need and reduce potential warpage issues.

CAE Cooling analysis helps to determine:

Click play to watch a brief on our "Circuiting Done Right" article by our Director of Engineering, Tim Lankisch.

MoldMaking Technology's April 2013 issue

Consulting | Software | Training:

Improved Part Quality

Faster Cycle Times

Larger Processing Window

Less "Fire Fighting"

More Profit