2-Shot Overmolding

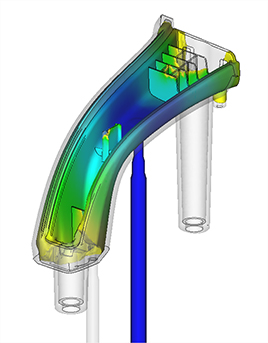

Overmolding is an injection molding process where two materials are molded together. Types of overmolding include two-shot sequential overmolding, multi-shot injection molding or insert overmolding. Unique part designs using different materials, sections, and colors can be a time-consuming and expensive proposition. Before beginning this delicate process, a 2-shot overmolding simulation and analysis will help determine how best to design the part and specifically where the best gate location would be and how the materials will function throughout the first or second shot as well as during a multiple shot molding cycle.

CAE 2-shot Overmolding Analysis helps determine:

- The best gate location

- Optimal material flow for multiple shots

- How an insert can be place for efficient molding

Two-shot sequential overmolding is where the molding machine injects the first material into a closed cavity, and then moves the mold or cores to create a second cavity, using the first component as an insert for the second shot using a different material.

Multi-shot injection molding injects multiple materials into the cavity during the same molding cycle.

Insert overmolding uses a pre-molded insert placed into the mold before injecting the second material.

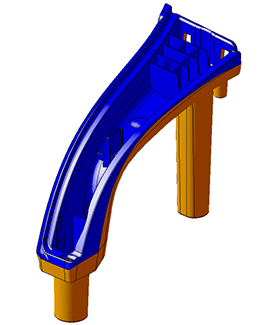

1st Shot (Substrate)

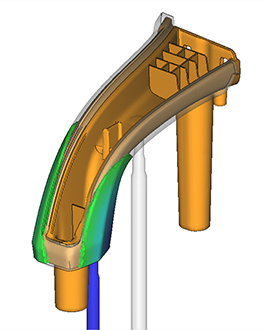

2nd Shot (Overmold)

3D 2-shot Flow Rear Door Pistol Grip

Consulting | Software | Training:

Improved Part Quality

Faster Cycle Times

Larger Processing Window

Less "Fire Fighting"

More Profit