DFM

"DFM, the optimization of a part design in order to reduce manufacturing costs."

Over several decades, CAE Services has analyzed tens of thousands of plastic injection molds. No matter what type of part, no matter what material is being used, one thing is always true about plastic – the design matters! Our experience over the years has taught us that many injection molding problems can be avoided by paying attention to good part design and mold design standards. That’s where part feasibility comes in. By doing in-depth part feasibility studies up front, many of the problems that occur in the manufacturing process can be improved before we even start optimizing things thru Moldflow simulation. The following are included:

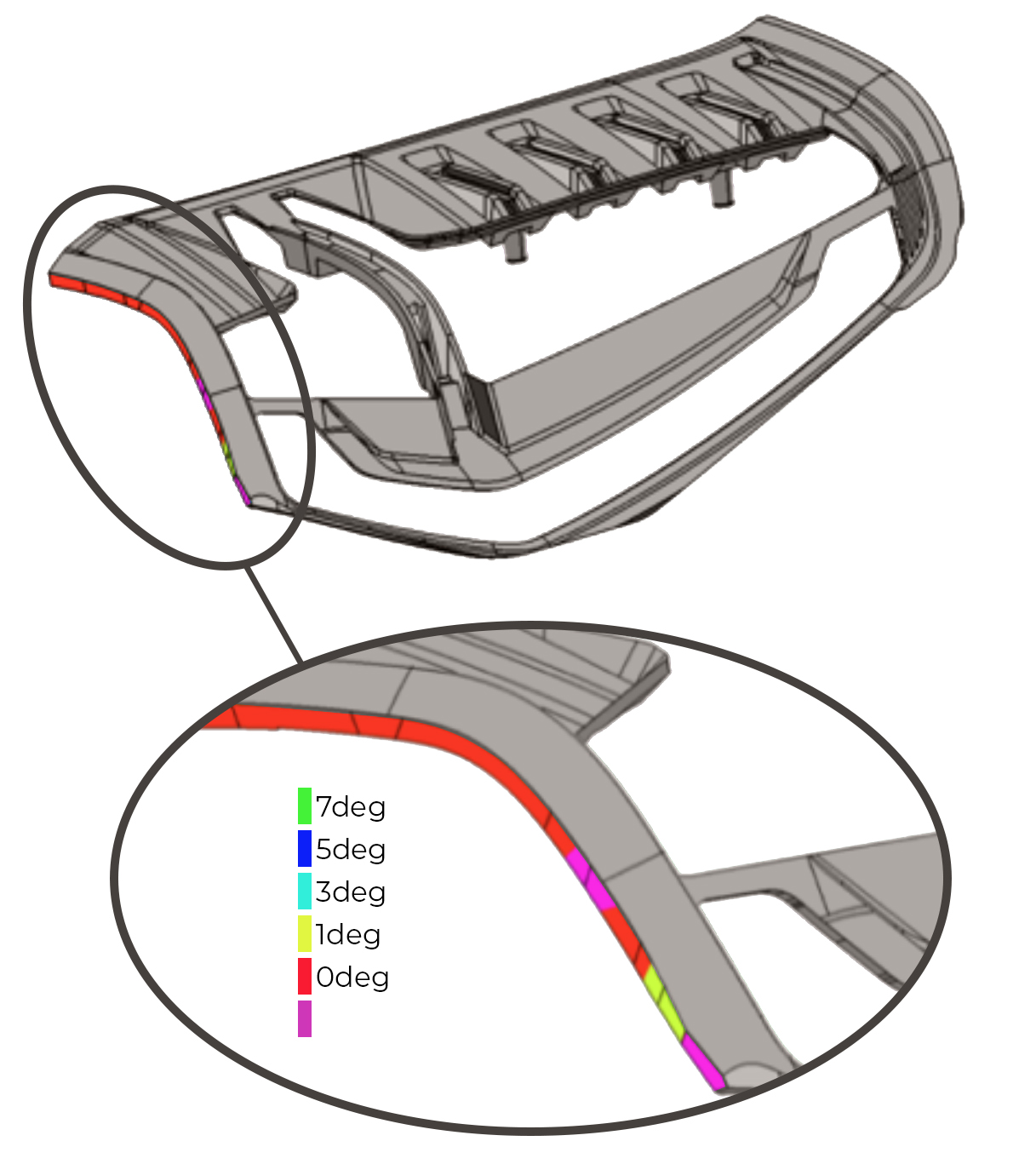

- Wall Stock Check – helps identify excessive wall stock variation to avoid excessive shrinkage variation;

- Draft Analysis – identifies areas that need attention;

- Tooling Action – Identifies which areas/feature of the part will require lifters/slides, etc.

Design For Manufacturing

Focusing on the design stage will significantly reduce the final production costs. CAE services offers (3) levels of DFM.

DFM Deliverables

Level I Design For Manufacturing (DFM-L1)

Level II Design For Manufacturing (DFM-L2)

Level III Design For Manufacturing (DFM-L3)

Request DFM