Gas Assist Analysis

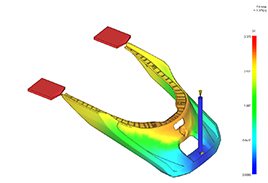

Determining proper gate placement, best gas channel layout, and overall part design are key steps to ensuring your part is produced properly. All of our analyses are comprehensive and can be used to supplement the other. With our gas-assist analysis, we inject an inert gas into the molded part during the filling analysis stage (see Packing Analysis). This compressed gas packs the opening of the part and provides a mechanical strength and stability for thick molded geometry. This analysis will help with cost savings in energy, materials, and part weight.

CAE Gas-Assist Analysis helps to determine:

Consulting | Software | Training:

Improved Part Quality

Faster Cycle Times

Larger Processing Window

Less "Fire Fighting"

More Profit