Injection Compression Simulation

Making sure that your part materials and design are optimized to save time, money, and effort is every engineer’s and project manager’s number one goal. Our injection compression molding analysis is an important first step to reaching that goal. This simulation combines injection and compression molding techniques. The compression phase of the simulation can be programmed to begin before, during, or after the polymer injection to test the different molding results and to evaluate materials and design as well as the overall process.

CAE Injection Compression helps to determine:

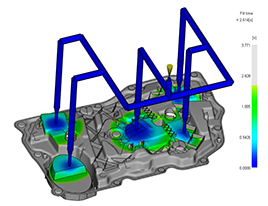

Shown above is the extent of melt front advancement for the instant at which the process switches from injection to compression.

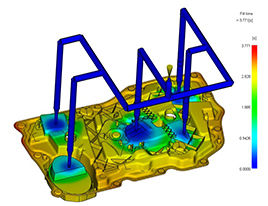

Shown here is the melt front advancement at the end of compression, indicating that the mold filled completely.

Consulting | Software | Training:

Improved Part Quality

Faster Cycle Times

Larger Processing Window

Less "Fire Fighting"

More Profit