Consulting | Software | Training:

Improved Part Quality

Makes Customers Happy 🙂

Faster Cycle Times

Max Overall Equipment Effectiveness (OEE)

Larger Processing Window

Doesn't Require the "Wizard" to Set it Up

Less "Fire Fighting"

Means High Priority Projects Get Attention

More Profit

Boss Looks Great, We All Look Great!

Applying windage and model-morphing techniques saved toolmaker/molder Sturgis Molded Products the time, cost, headaches of multiple part/mold design iteration loops, cumbersome cooling, fixtures and long molding cycles.

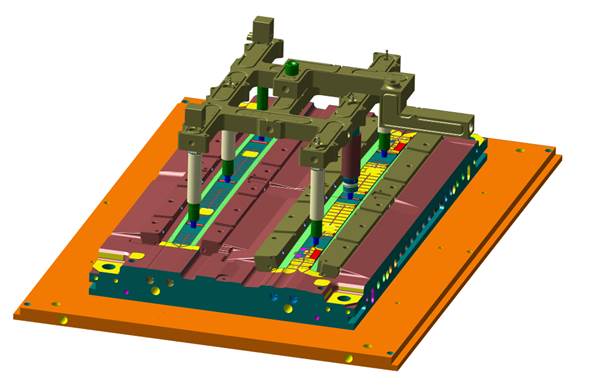

Figure 1

Founded in 1966, Sturgis Molded Products (SMP) in Sturgis, Michigan, is a large, family-owned, custom injection molder that manages nearly all of its own tooling. SMP operates four plants with a combined area of 215,000 square feet/19,974 square meters. The company employs 215 associates, molds 200 different materials, maintains 600 active molds and is equipped with 70 injection molding presses—ranging in size from 50 to 1,900 tons/tonnes—plus a fully equipped tool room. Sturgis combines its 50+ years of experience in part and mold design, engineering and production with scientific injection-molding techniques to produce precision components for customers in the automotive, commercial truck, medical device and furniture markets.

Inheriting Problems

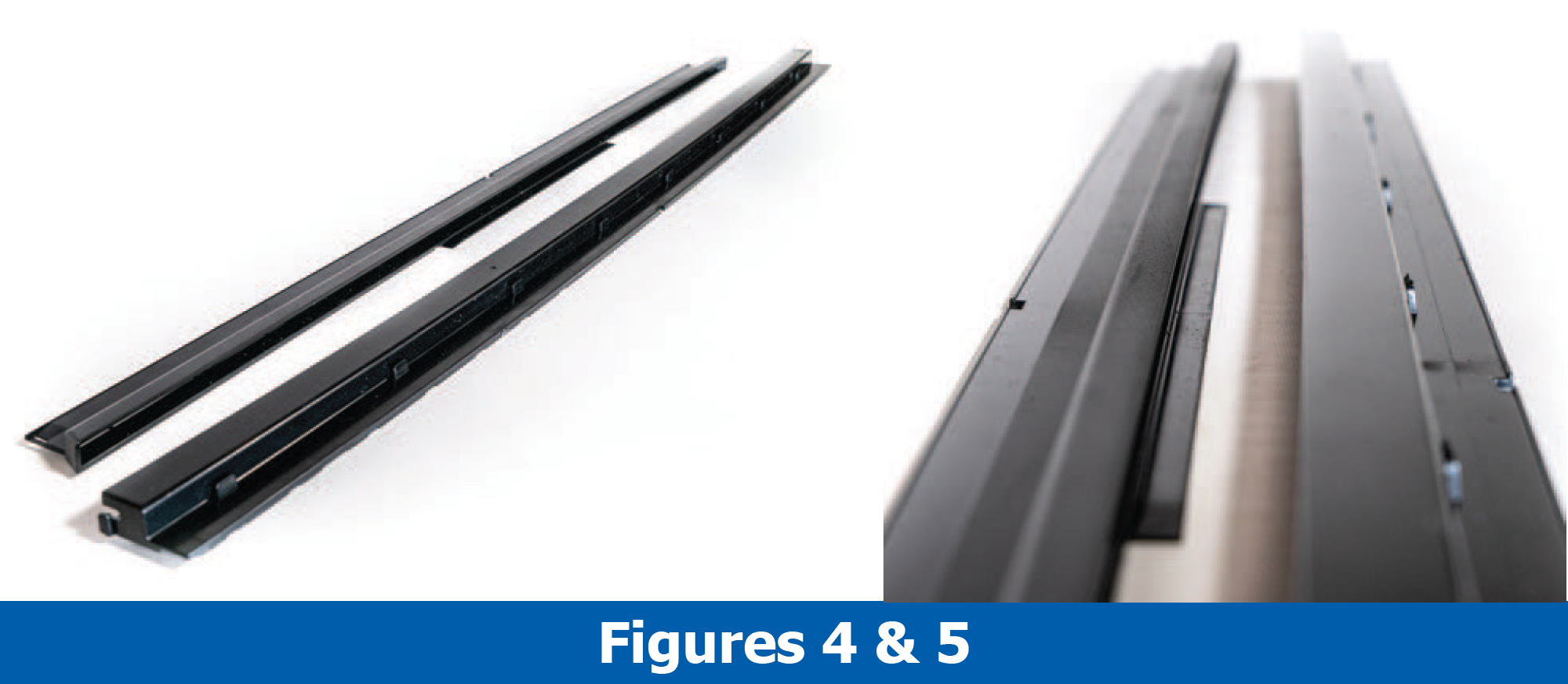

A few years ago, Sturgis was asked by one of its Tier 1 customers, who also molds, to take over production of a structural sliding-window rail system, which permits rear pickup windows to slide open and closed. Even though the material being molded was unreinforced and unfilled polycarbonate/acrylonitrile butadiene styrene (PC/ABS), an amorphouscopolymer, the fact that the part’s geometry was a 50+-inch-/127+-centimeter-long and thin U-channel meant that it wasprone to warpage due to post-mold residual-stress relaxation. Hence, along with a four-cavity tool for the program (to mold two upper and two lower rails), Sturgis also inherited a long molding cycle and elaborate cooling fixtures to help deal with the parts’ tendency to warp. Initially, SMP tried changing process conditions to reduce warpage, shorten cycle times and eliminate the cooling fixtures, but eventually, it made do with what it had. A few years into molding rails for that program, Sturgis was asked to quote both a set of tools and molding services for the newest model of that highvolume pickup.

“We said to our Tier 1 customer, ‘We’ll be happy to quote that tool, but we think we can make it in such a way that the warpage problem is eliminated,’” Paul Feaman, SMP vice president of engineering, says.

Sturgis Molded Products

Problem:

50+-inch-long injection molded rail was predicted to warp in two directions, necessitating an elaborate cooling fixture and long cooling times.

Solution:

Before steel was cut, had CAE Services apply Kentucky windage and CAD model-morphing techniques to fix warpage problems while still meeting OEM performance requirements.

Results:

Not only did tool work perfectly, and parts mold without warpage, but the molding cycle was reduced for this high-volume automotive program.

“We knew from our experience on the previous program that these parts liked to warp, and our own process simulations estimated the direction and magnitude of the warpage we could expect on the new program.”

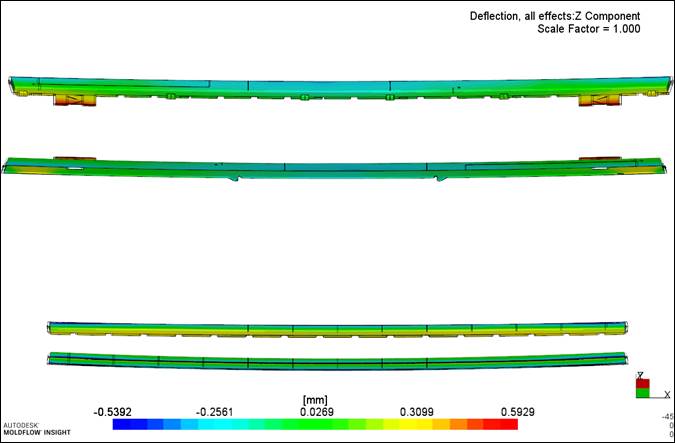

“As we have Moldflow in-house, our initial simulation results predicted that the part would oil-can inward along the length of the U-channel and thencurve downward on both ends like a frown,” recalls Jordan Avery, SMP engineering director.

While Sturgis was still in the conceptual stage on the new tool, team members used all their process knowhow from the previous program, plus all of their engineering knowhow on both part and mold designs, to see if they could eliminate the warpage issues. “When conventional means failed to eliminate the problem, we knew it was time to bring in some other experts,” Mark Jarrett, SMP senior program manager says.

Figure 2

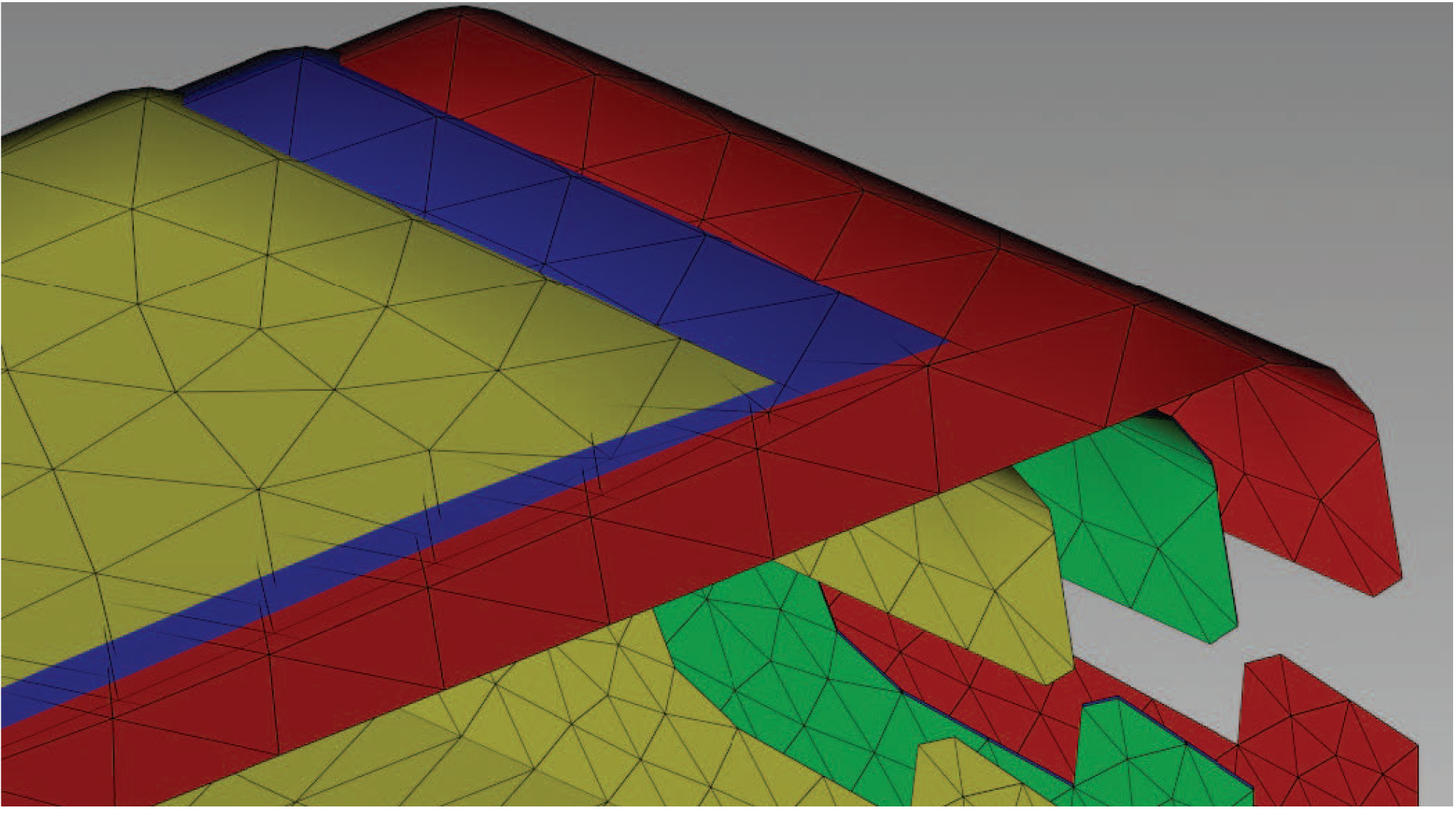

Figure 3

Working Out the Kinks

Sturgis turned to Batavia, Illinois-based CAE Services Corp., which also maintains offices in Grand Rapids and Rochester Hills, Michigan, and Windsor, Ontario, Canada. The 34-year old company specializes in process-simulation work on injection molded thermoplastic parts and also trains, mentors and resells Moldflow process-simulation software from Autodesk, Inc. of San Rafael, California. At its Batavia technology center, the company also has three injection presses ranging in size from 67 to 500 tons/tonnes, plus auxiliary equipment to help customers learn analysis implementation, process training and mold sampling.

CAE Services is especially proficient in applying Kentucky windage and mold-morphing techniques during design and simulation work to solve warpage problems. “We’re well known for our expertise in this area, especially in the automotive industry,” Tim Lankisch, CAE Services director of engineering says. “Our staff can evaluate all aspects of part design and the molding process to solve warpage issues and reduce the time and costs involved in design and mold sampling loops using trial-and-error approaches.”

CAE Services exports the reverse of Moldflow’s own warpage predictions—which a moldmaker can’t use directly to modify tool design—and pulls them back into CAD models of the mold to try and morph the design in areas where warpage is predicted, and to protect features from die-lock conditions. The morphed CAD model is then pulled back into Moldflow, where another process simulation is run to make sure the part flattens out. If it doesn’t, or if warpage shifts to another area, then the morphed model is tweaked until acceptable results are achieved. All work is done virtually before the first piece of steel is cut.

Problem Solved

“We already had good surrogate data on this warpage problem from our experience running the previous tools for several years,” says Scott Gooch, SMP metrology manager, who adds that Sturgis’ resin supplier on this project provided CAE Services with the CRIMS (corrected residual in-mold stress) material data needed for quick success.

They used the minor design modifications CAE Services gave them to cut the core and cavity to the morphed model. Then, once they trialed that first mold, the material shrank as predicted and produced parts that were the correct shape and dimensions. Not only did the new parts not warp, but Sturgis was able to eliminate the earlier cooling fixtures and lower cycle times, which represents a sizable productivity increase—especially on a program of this size. “That can mean the difference between needing two tools running fulltime to meet production targets and three,” Jarett says.

“The speed with which CAE Services was able to solve the problem easily saved us weeks, if not months, and tens of thousands of dollars versus taking the old ‘make & break’ approach of modifying a tool, molding parts to see if it worked, and, if it didn’t, modifying the mold again, making parts again, and so forth,” Avery says.

Lankisch says his team followed their well-established process for applying windage and mold-morphing techniques. “What we’d like molders, moldmakers and part designers to understand is that when they’ve exhausted all the traditional simulation solutions to solving warpage problems, they can rely on our engineering expertise to fix the problem for them—usually in one to two weeks, sometimes even faster,” adds Lankisch.

Since that project, Sturgis Molded Products has picked up a number of additional components from other customers and has continued to partner with CAE Services to solve predicted warpage problems on new part and tool designs.

Consulting | Software | Training:

Improved Part QualityMakes Customers Happy :)Faster Cycle TimesMax Overall Equipment Effectiveness (OEE)Larger Processing WindowDoesn’t Require the “Wizard” to Set it UpLess “Fire Fighting”Means High Priority Projects Get AttentionMore ProfitBoss Looks Great, We All Look Great!

Company*Name*

First

Last

Email*

Phone*Comments*CAPTCHA

jQuery(document).ready(function($){gformInitSpinner( 2, ‘https://caeservices.com/wp-content/plugins/gravityforms/images/spinner.gif’ );jQuery(‘#gform_ajax_frame_2’).on(‘load’,function(){var contents = jQuery(this).contents().find(‘*’).html();var is_postback = contents.indexOf(‘GF_AJAX_POSTBACK’) >= 0;if(!is_postback){return;}var form_content = jQuery(this).contents().find(‘#gform_wrapper_2’);var is_confirmation = jQuery(this).contents().find(‘#gform_confirmation_wrapper_2’).length > 0;var is_redirect = contents.indexOf(‘gformRedirect(){‘) >= 0;var is_form = form_content.length > 0 && ! is_redirect && ! is_confirmation;var mt = parseInt(jQuery(‘html’).css(‘margin-top’), 10) + parseInt(jQuery(‘body’).css(‘margin-top’), 10) + 100;if(is_form){jQuery(‘#gform_wrapper_2’).html(form_content.html());if(form_content.hasClass(‘gform_validation_error’)){jQuery(‘#gform_wrapper_2’).addClass(‘gform_validation_error’);} else {jQuery(‘#gform_wrapper_2’).removeClass(‘gform_validation_error’);}setTimeout( function() { /* delay the scroll by 50 milliseconds to fix a bug in chrome */ jQuery(document).scrollTop(jQuery(‘#gform_wrapper_2’).offset().top – mt); }, 50 );if(window[‘gformInitDatepicker’]) {gformInitDatepicker();}if(window[‘gformInitPriceFields’]) {gformInitPriceFields();}var current_page = jQuery(‘#gform_source_page_number_2’).val();gformInitSpinner( 2, ‘https://caeservices.com/wp-content/plugins/gravityforms/images/spinner.gif’ );jQuery(document).trigger(‘gform_page_loaded’, [2, current_page]);window[‘gf_submitting_2’] = false;}else if(!is_redirect){var confirmation_content = jQuery(this).contents().find(‘.GF_AJAX_POSTBACK’).html();if(!confirmation_content){confirmation_content = contents;}setTimeout(function(){jQuery(‘#gform_wrapper_2’).replaceWith(confirmation_content);jQuery(document).scrollTop(jQuery(‘#gf_2’).offset().top – mt);jQuery(document).trigger(‘gform_confirmation_loaded’, [2]);window[‘gf_submitting_2’] = false;}, 50);}else{jQuery(‘#gform_2’).append(contents);if(window[‘gformRedirect’]) {gformRedirect();}}jQuery(document).trigger(‘gform_post_render’, [2, current_page]);} );} ); jQuery(document).bind(‘gform_post_render’, function(event, formId, currentPage){if(formId == 2) {if(typeof Placeholders != ‘undefined’){

Placeholders.enable();

}jQuery(‘#input_2_4’).mask(‘(999) 999-9999’).bind(‘keypress’, function(e){if(e.which == 13){jQuery(this).blur();} } );} } );jQuery(document).bind(‘gform_post_conditional_logic’, function(event, formId, fields, isInit){} ); jQuery(document).ready(function(){jQuery(document).trigger(‘gform_post_render’, [2, 1]) } );