Windage Analysis

Part design is frozen... can't change material, and warpage is unacceptable!

Now what?

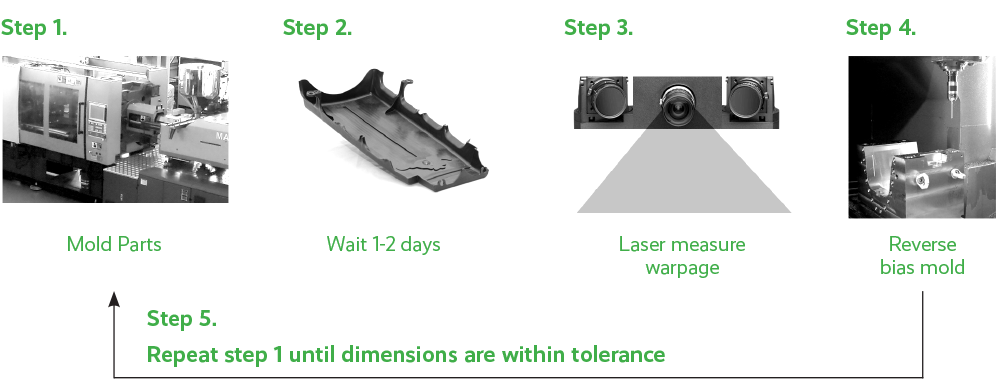

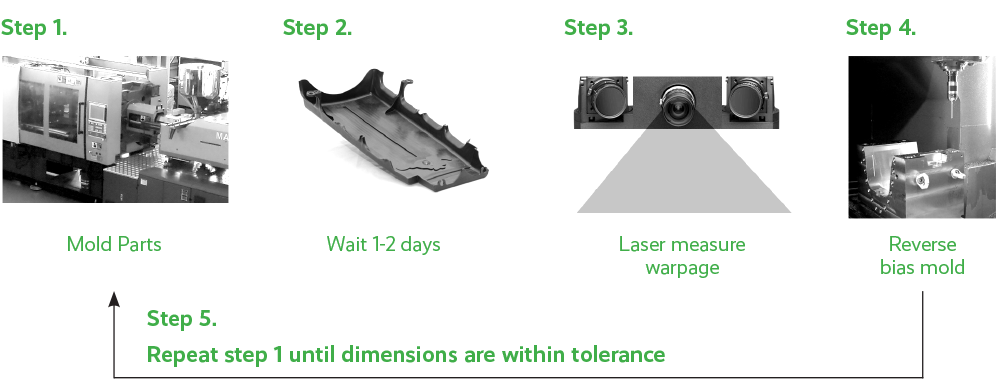

The old way... Kentucky Windage

“a method of biasing the mold cavity in the opposite direction of the measured warpage in order to have the part warp into its intended shape.”

Trial & error can often take several “tuning loops”, costing time and money (mold changes, material, and additional sampling) until the issue is resolved. Today, this method is too expensive and time-consuming.

A cost effective approach to solving warpage.

The New Way!

Today, we have the analysis capabilities to predict windage adjustments to the shape of the mold prior to cutting steel, thus saving time & money.

Our Process...

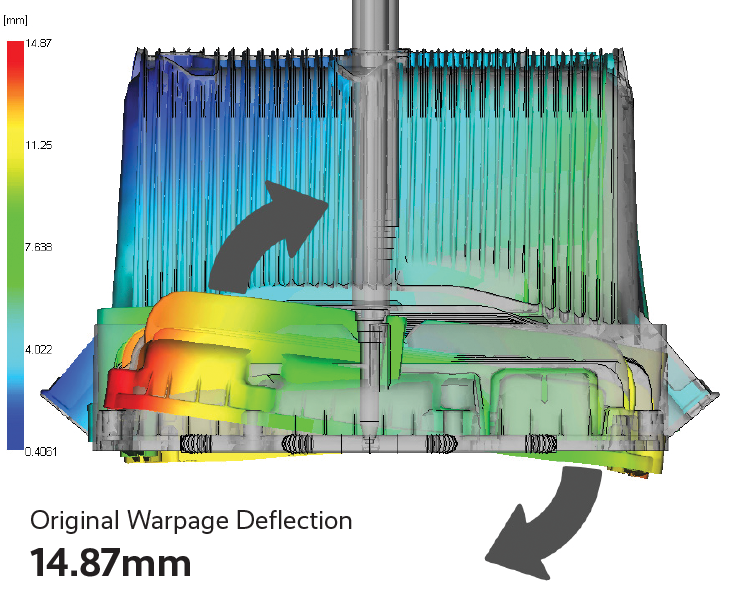

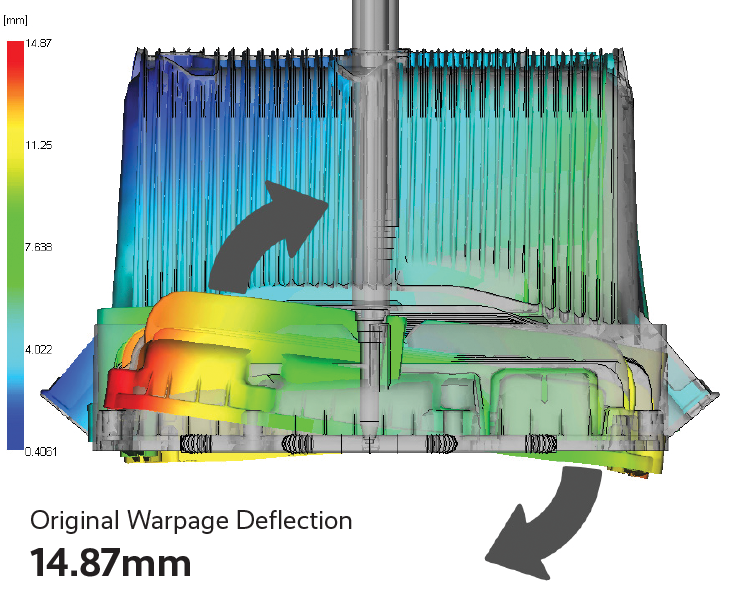

- CAE Services predicts the warpage from the original design.

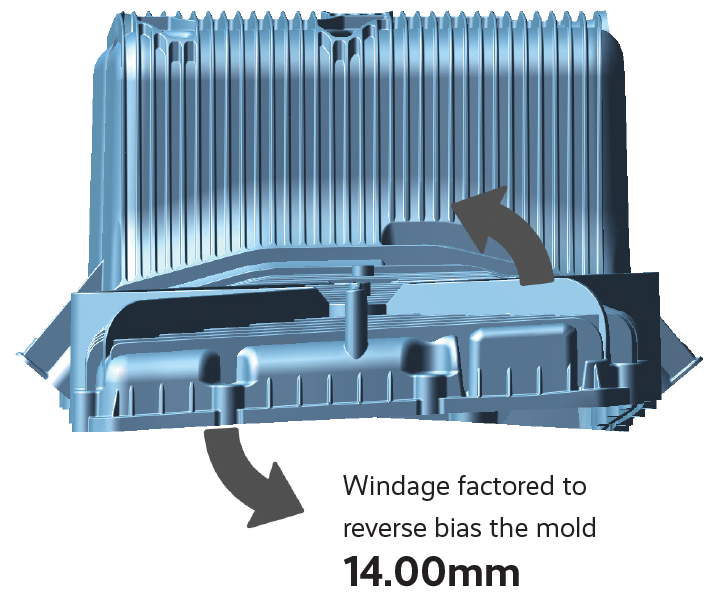

- Windage is then applied to the original model by multiplying the negative of that warpage.

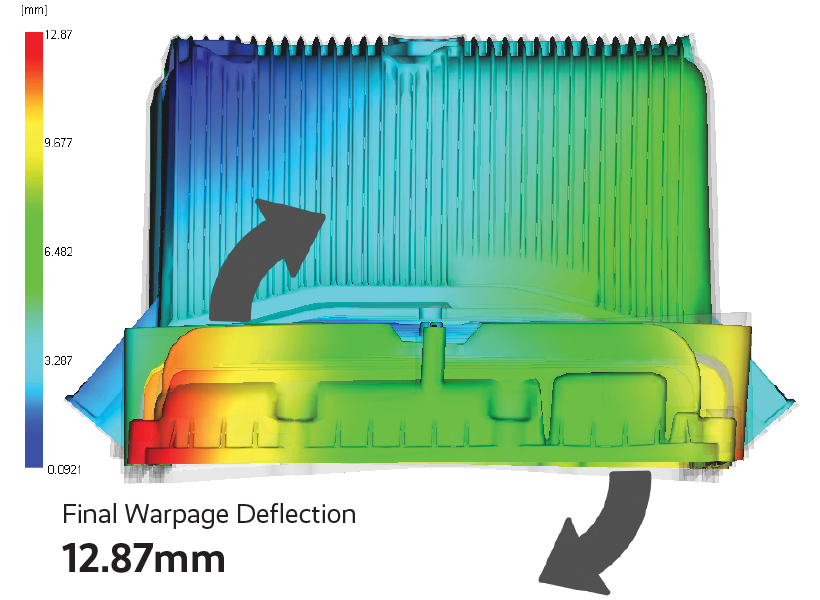

- Analyze windage model with the same gating and processing conditions to verify warpage tolerance.

- Not within tolerance? . . . re-analyze and adjust the windage factor until results are acceptable.

Warpage Objective Achieved

Before Cutting Steel!

Have an application?

Call us at 630.761.9898 and let’s discuss how we can help you save money by

“Getting it Right the 1st Time”.

Core Competency

FlowPackCoolWarpageWindage2-ShotGas AssistInj-CompressionCo-InjectionMuCell

Our Staff

Degreed EngineersExpert Certified Analysts Scientific Molding Certified

Technical Center

Consists of 3 molding machines for process training and correlation studies

Software Training

Chicago, ILDetroit, MIWindsor, ONT

Part design is frozen… can’t change material, and warpage is unacceptable!

Now what?

The old way… Kentucky Windage

“a method of biasing the mold cavity in the opposite direction of the measured warpage in order to have the part warp into its intended shape.”

Trial & error can often take several “tuning loops”, costing time and money (mold changes, material, and additional sampling) until the issue is resolved. Today, this method is too expensive and time-consuming.

A cost effective approach to solving warpage.

The New Way!

Today, we have the analysis capabilities to predict windage adjustments to the shape of the mold prior to cutting steel, thus saving time & money.

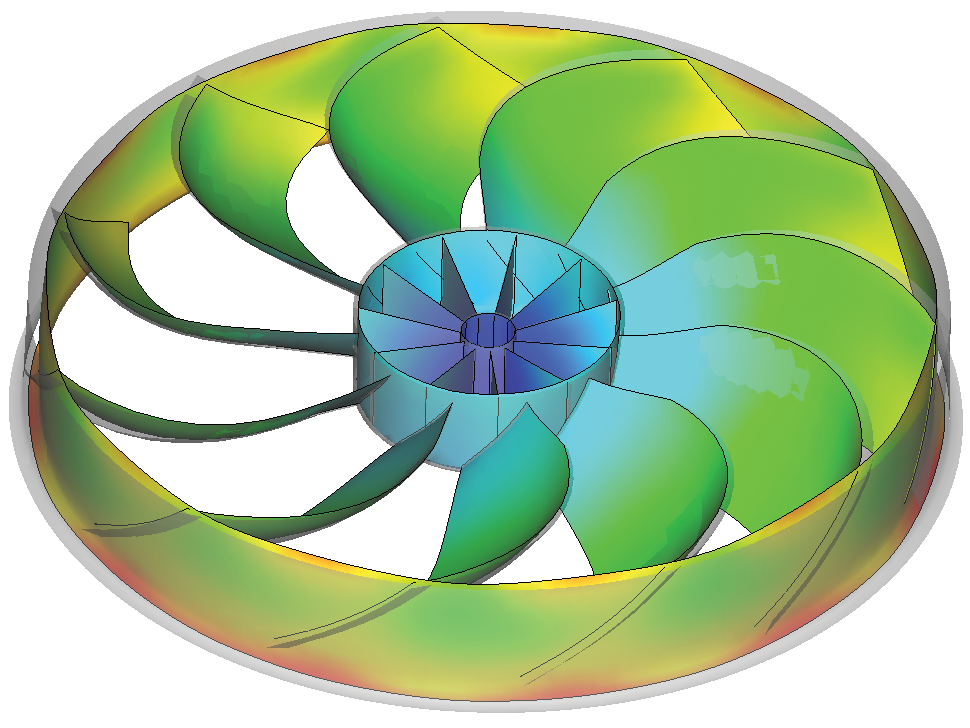

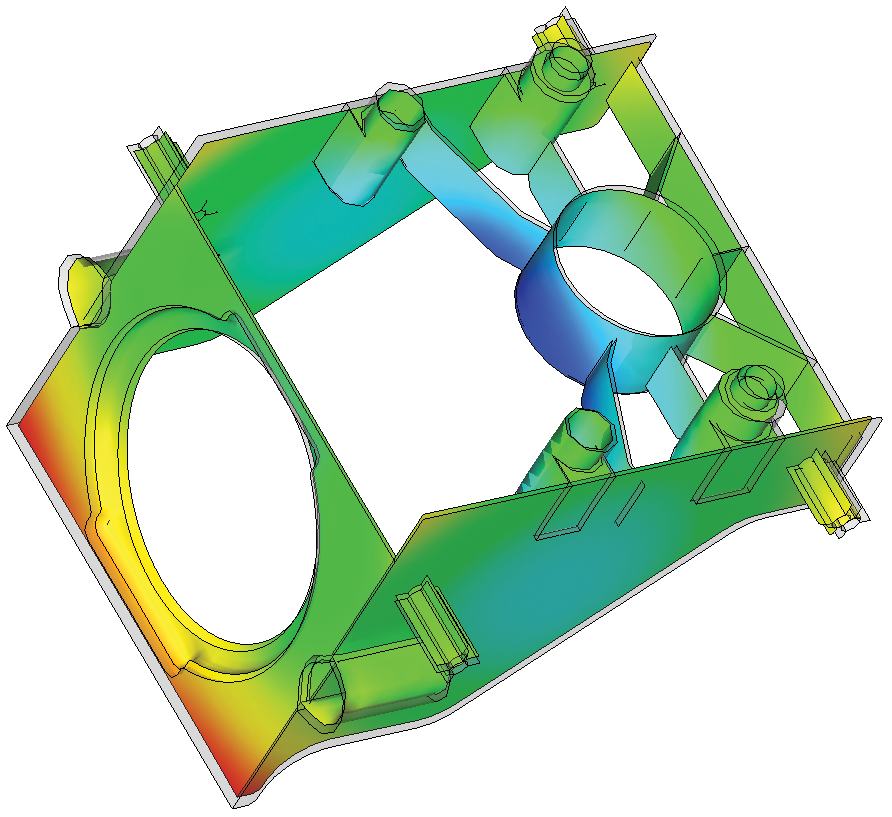

Total Deflection

Cooling Deflection

Orientation Deflection

Shrinkage Deflection

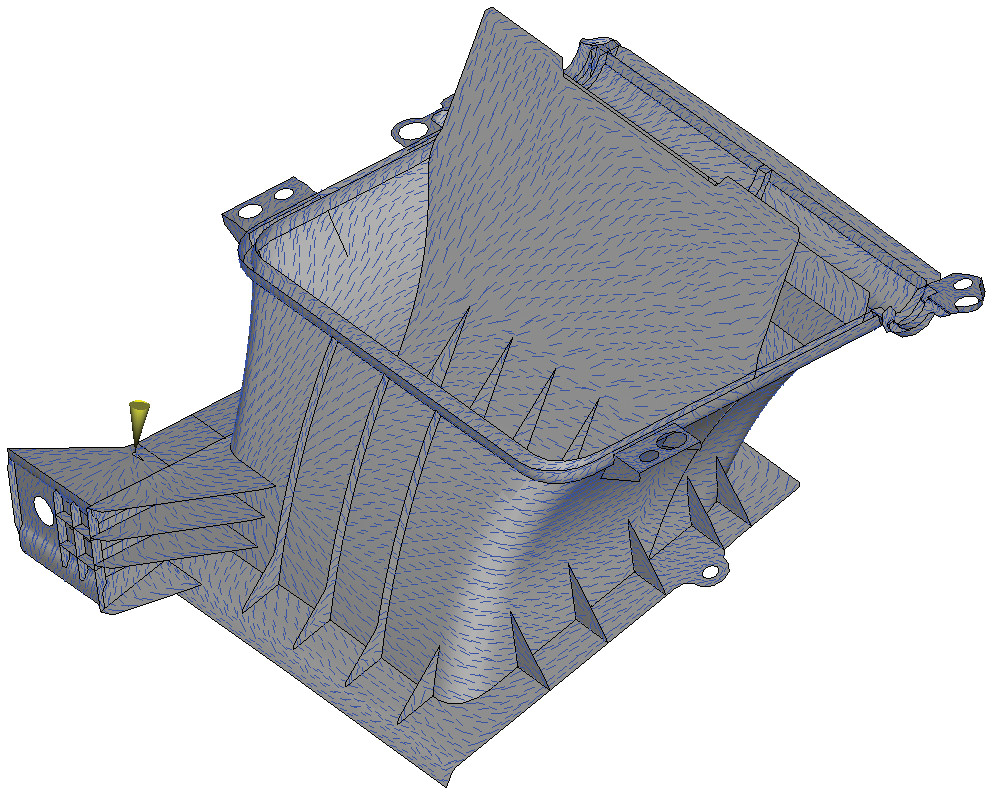

Material Orientation

Our Process…

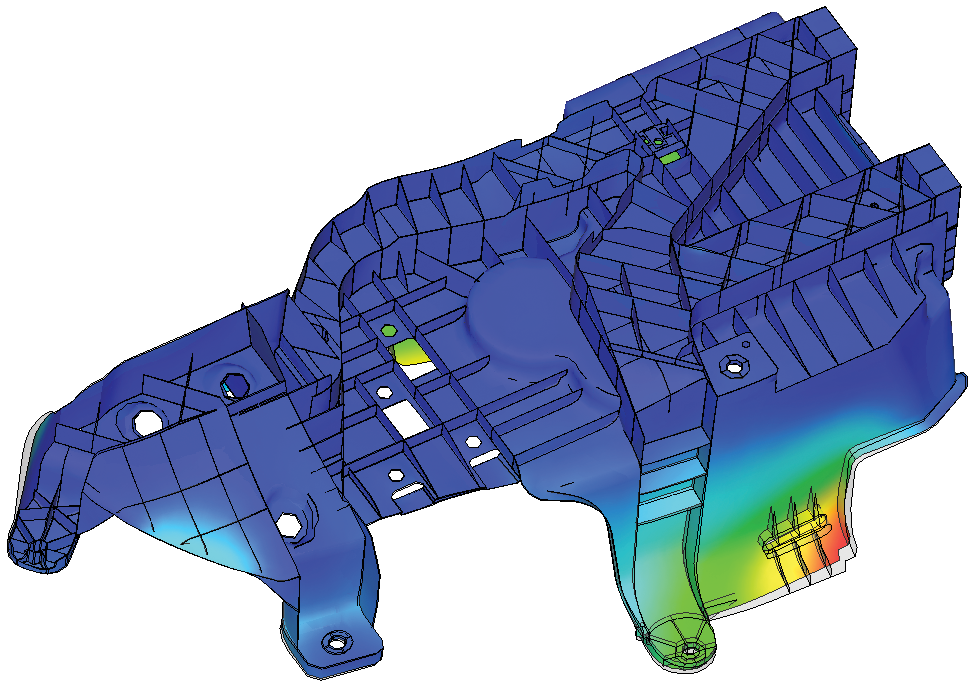

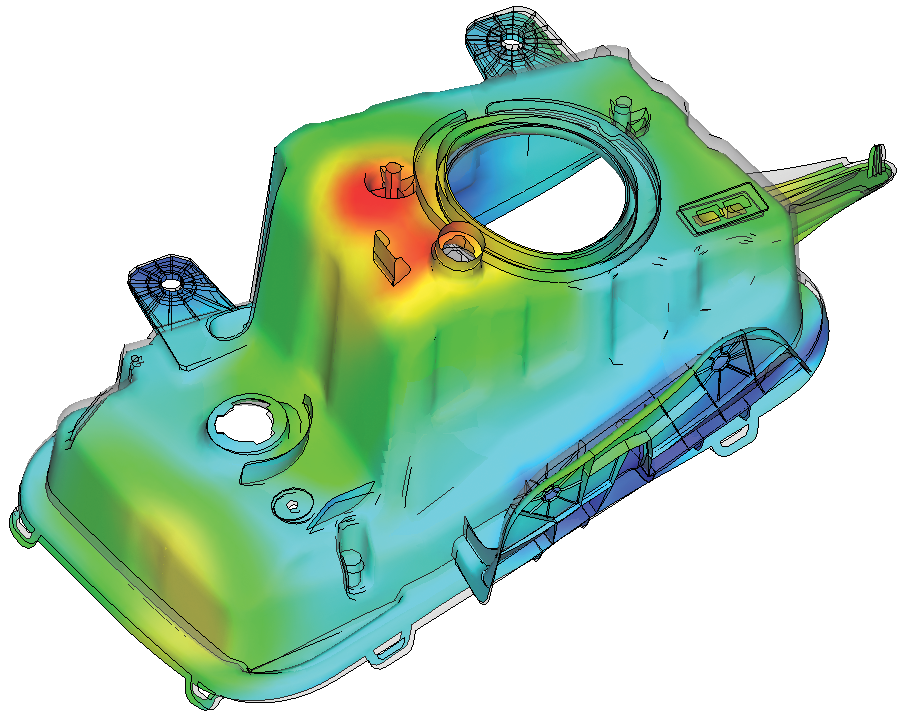

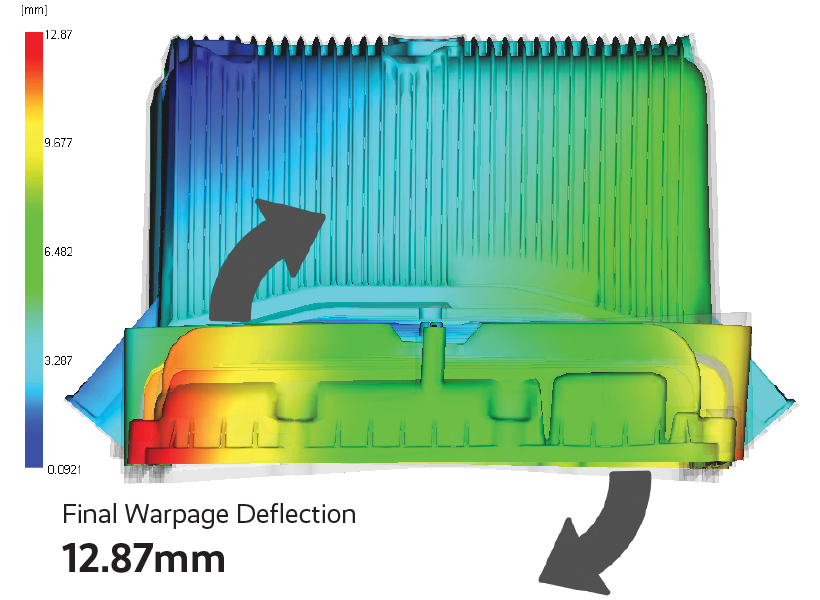

CAE Services predicts the warpage from the original design.

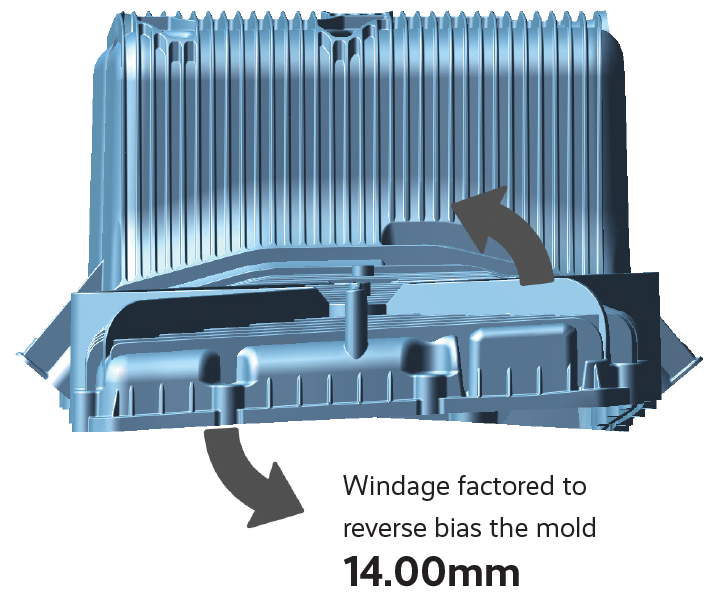

Windage is then applied to the original model by multiplying the negative of that warpage.

Analyze windage model with the same gating and processing conditions to verify warpage tolerance.

Not within tolerance? . . . re-analyze and adjust the windage factor until results are acceptable.

Warpage Objective AchievedBefore Cutting Steel!

Have an application?

Call us at 630.761.9898 and let’s discuss how we can help you save money by “Getting it Right the 1st Time”.