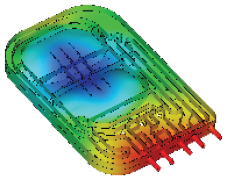

Moldflow Analysis Experts

Consulting Services for Automotive

Why Analysis?

What happens if the wrong gate location is selected, or if the mold fails to fill as required? Who pays the price? Moldflow analysis is an outstanding predictive engineering tool, a simulation tool which can identify potential problems or address uncertainty. Our scientific approach will save you both time and money.

Answers without wasting time or money!

- Identifying part design issues

- Reduce Ford engineering time

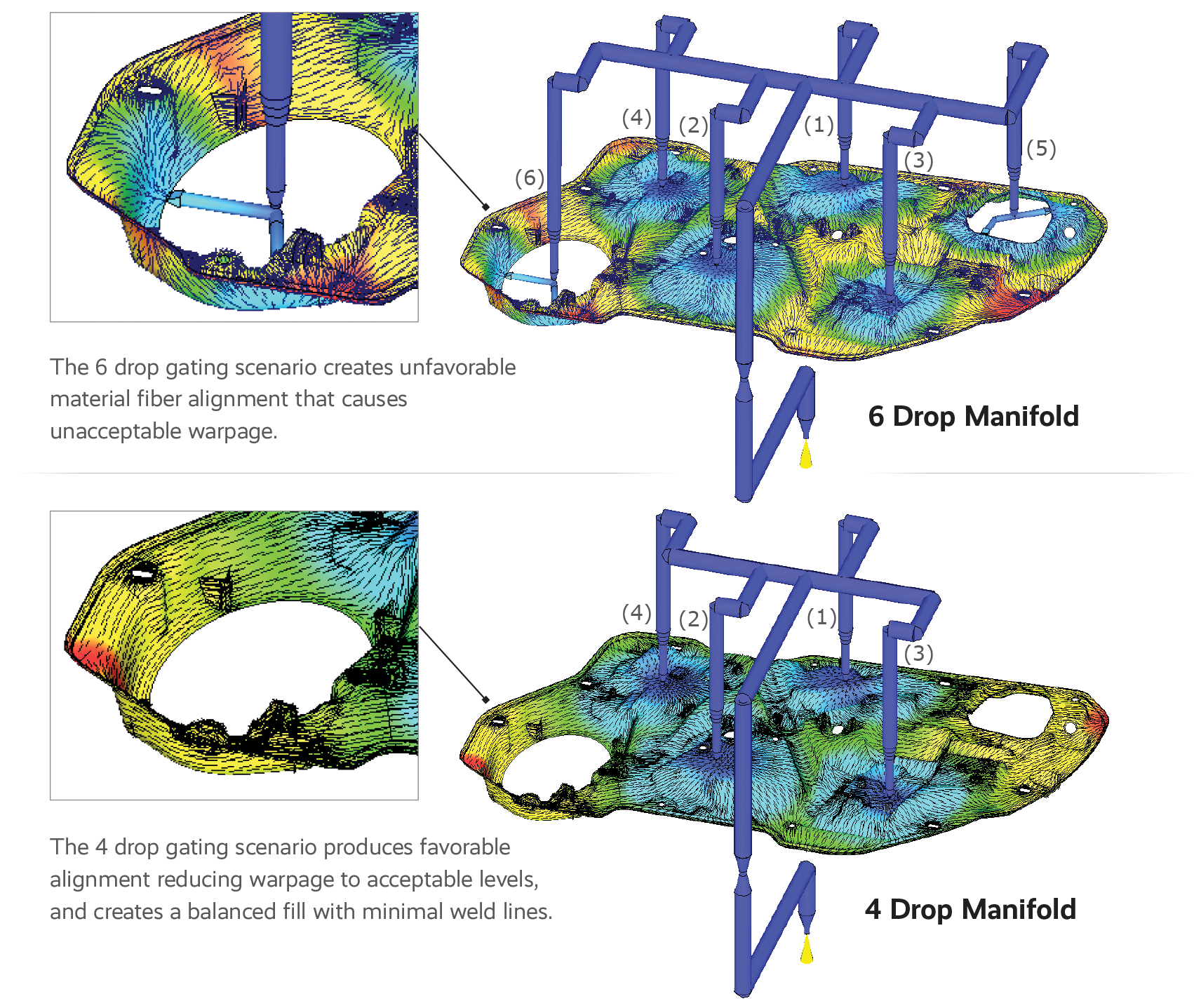

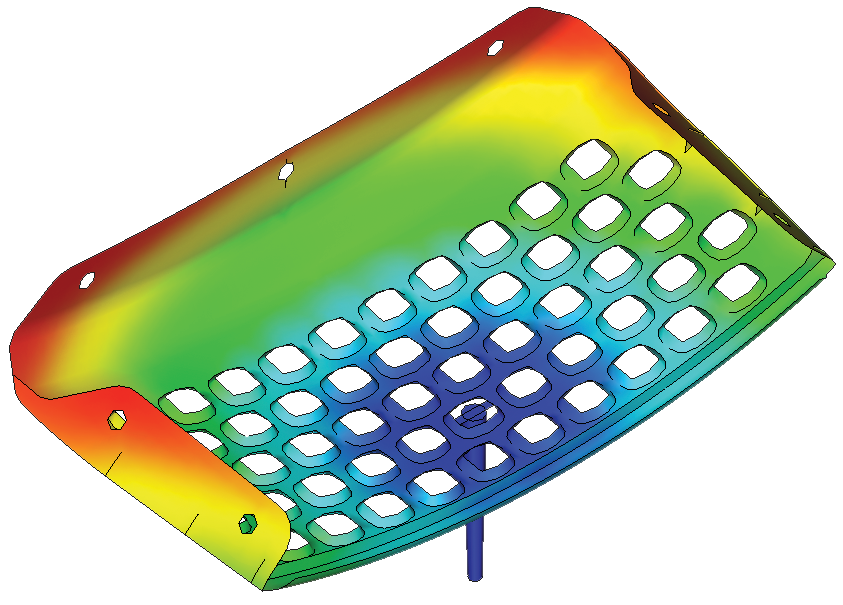

- Optimizing gate size/location

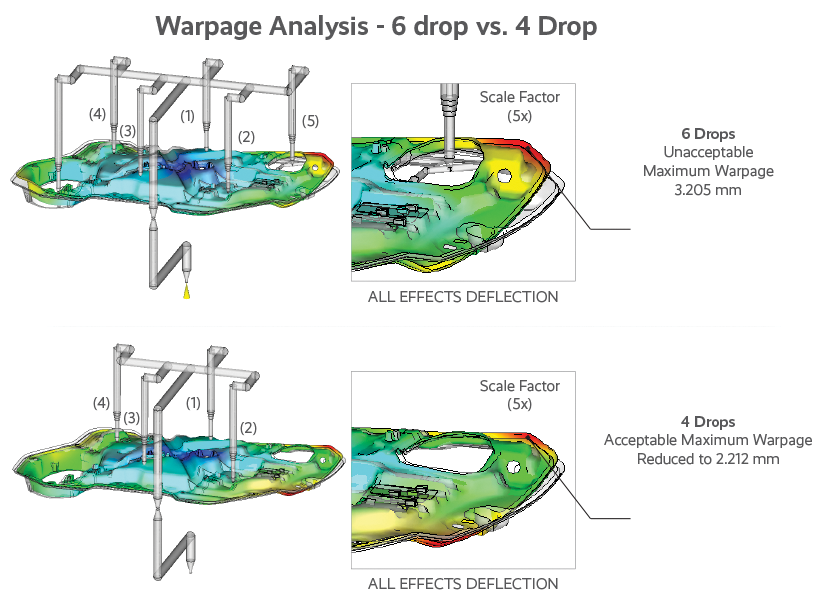

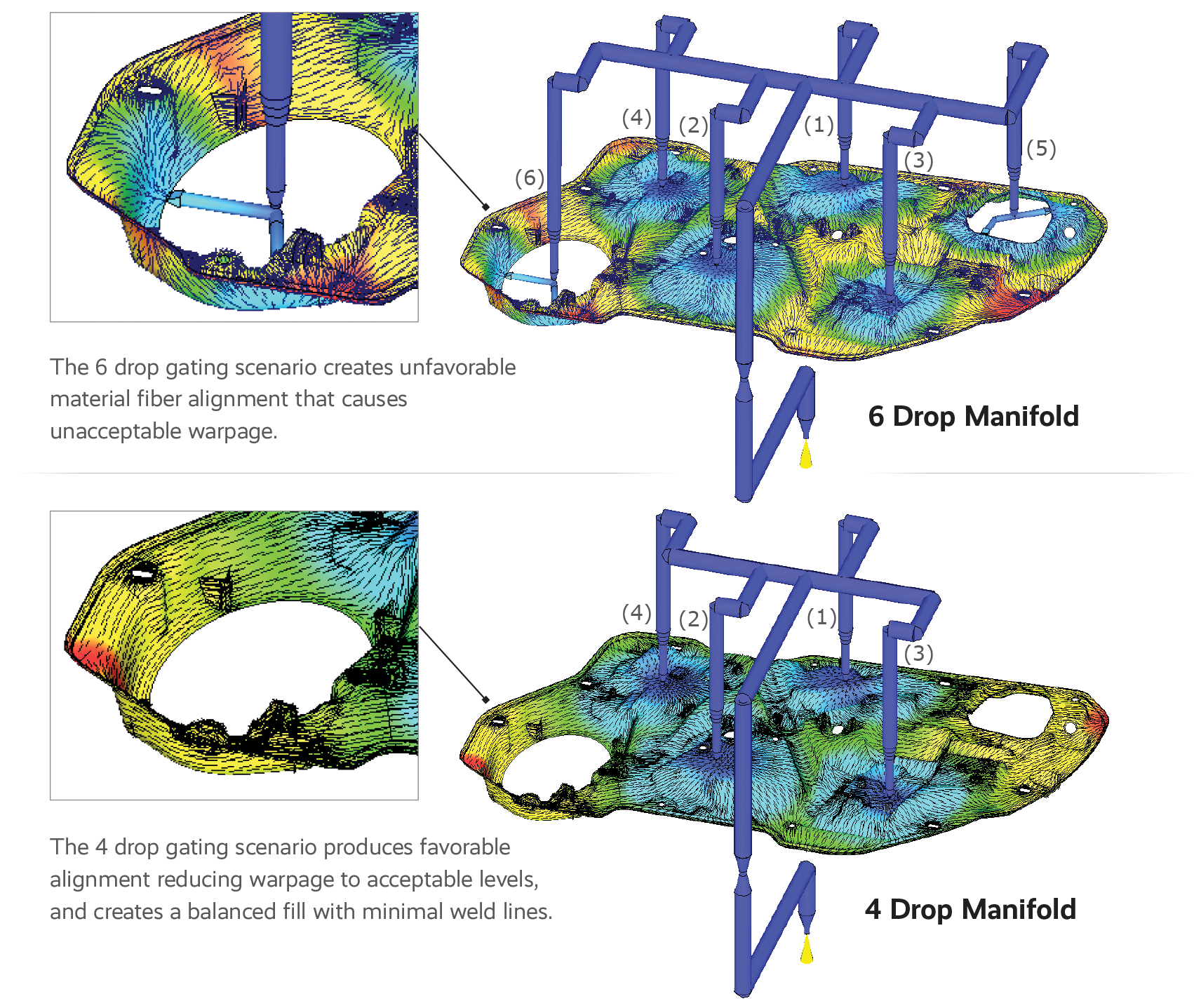

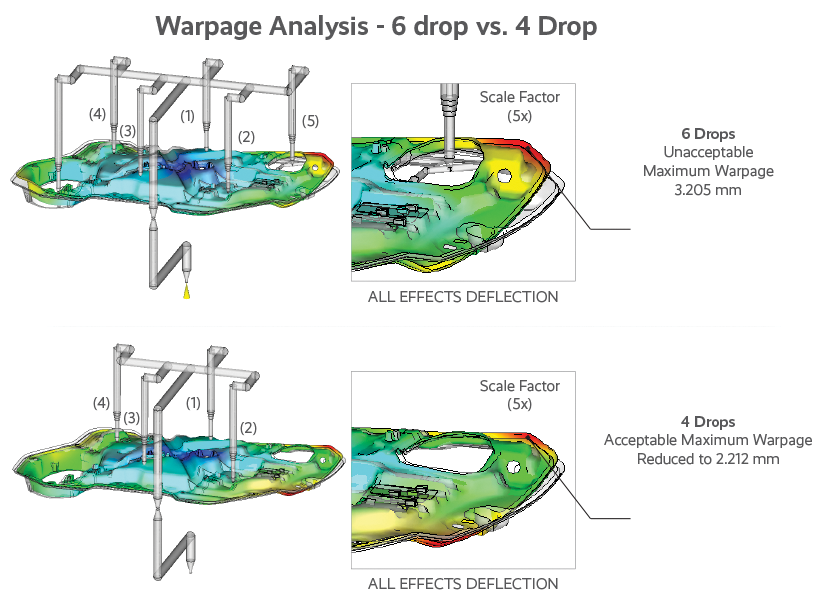

- Determine proper number of drops/gates

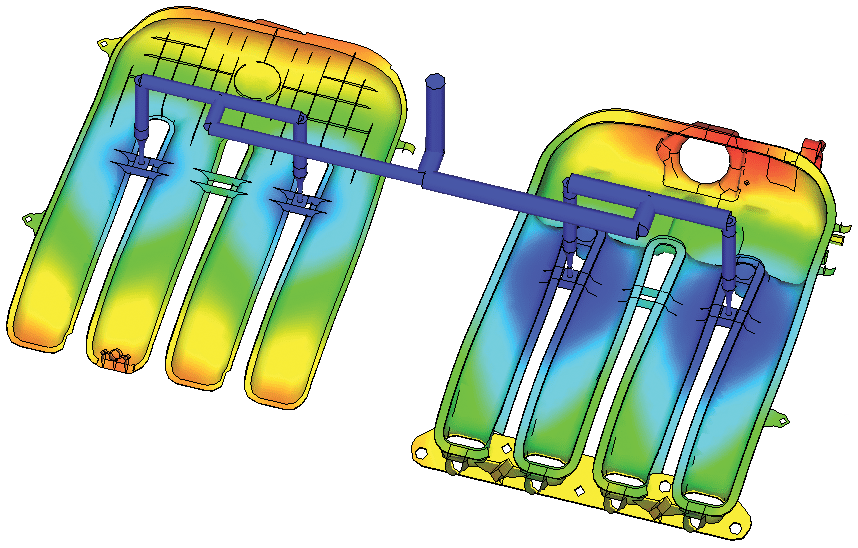

- Evaluate hot runner designs/SVG

- Define knit line locations

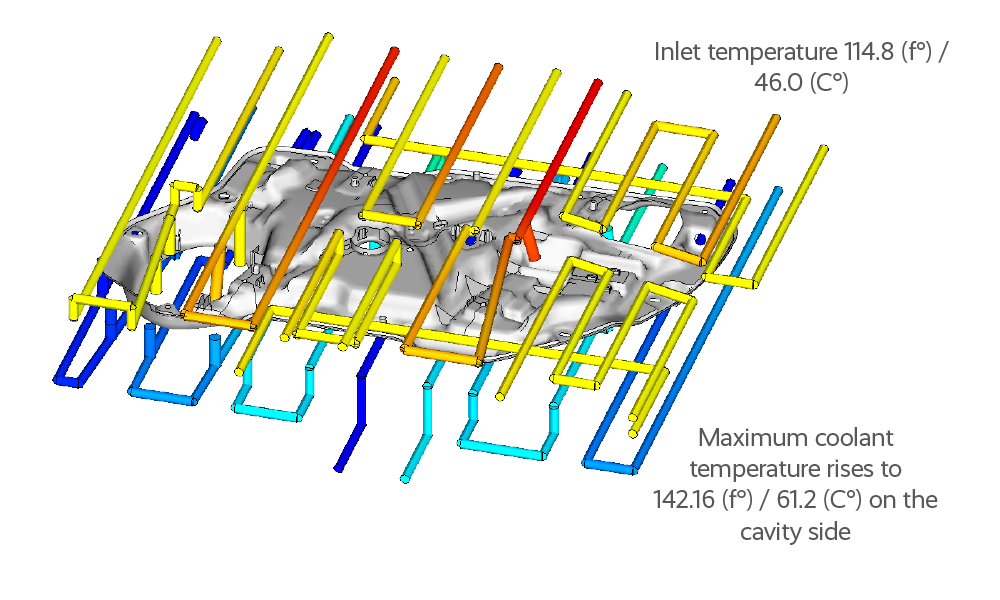

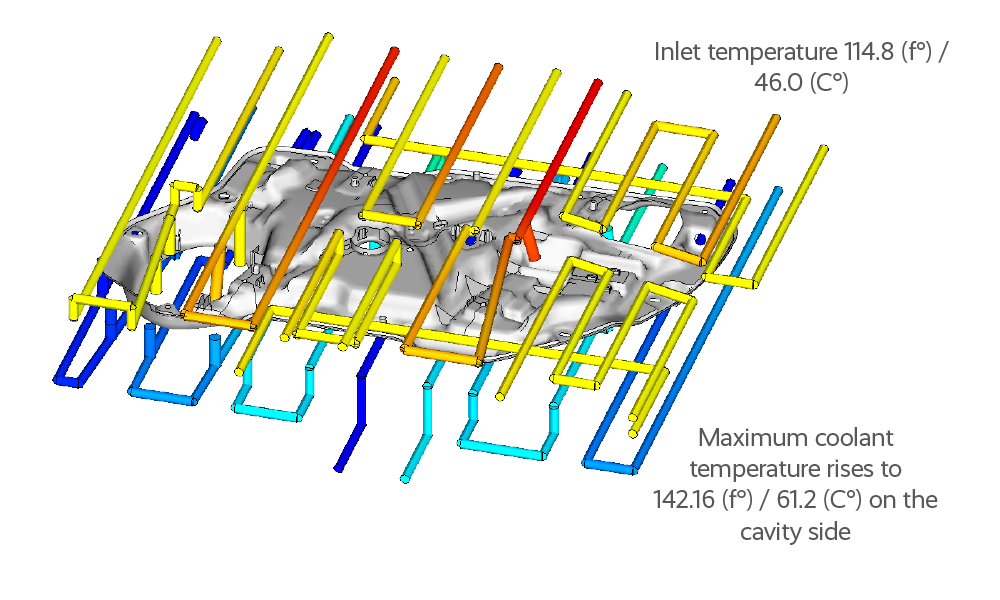

- Cooling design recommendations

- Reducing cycle times

- Elimination of shrink fixtures

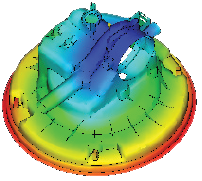

- Identify cause of warpage

- Minimize part warpage

- Reduce tooling costs

- Improve part quality

- Elimination of costly trial & error methods

Providing Answers

To eliminate uncertainty and to ensure your design can be molded successfully, you need answers, answers before “cutting steel”. Our experience is a “must have” for those interested in reducing costs and optimizing productivity.

Certified & Experienced

Don’t leave your decision to chance!

Your last project... Did you have gating issues? Problems with cycle times or issues with part warpage? If your goal is to reduce molding costs, improve cycle times and identify potential part warpage, then consider our consulting services. Our track record is exceptional!

Have an application?

Call us at 630.761.9898 and let’s discuss how we can help you save money by

“Getting it Right the 1st Time”.

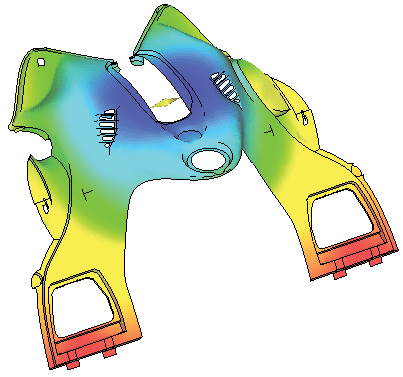

Consulting Services for Automotive

Automotive

Lighting

Appliance

Electronics

Containers

Packaging

Industrial

Medical

Furniture

Recreational

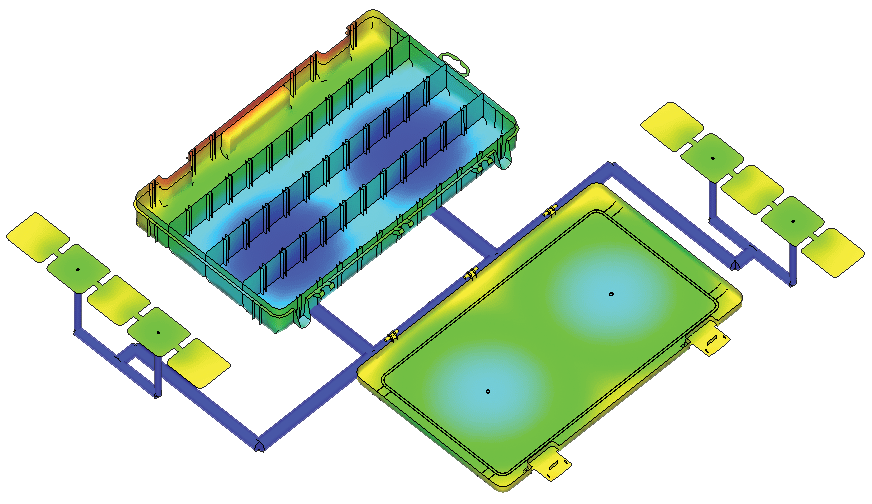

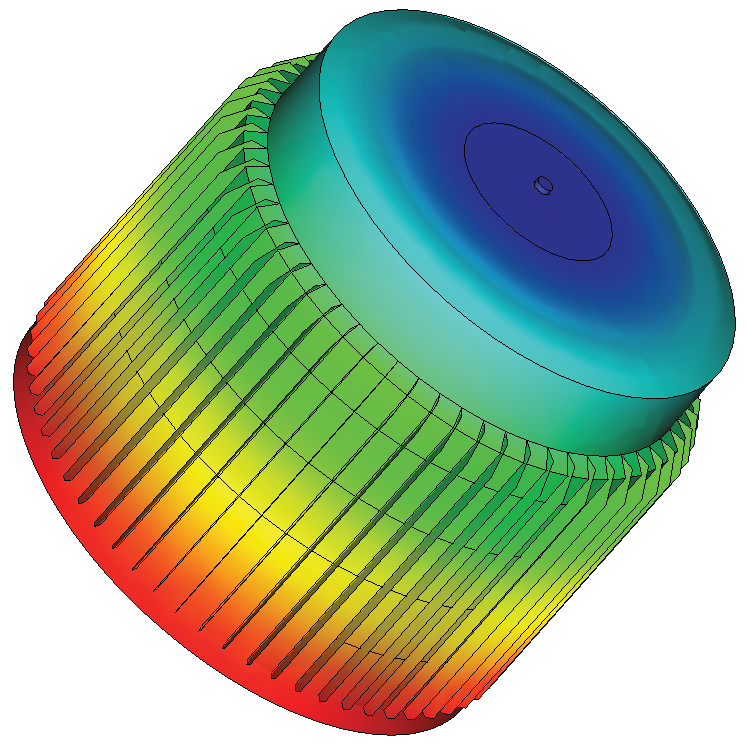

Why Analysis?

What happens if the wrong gate location is selected, or if the mold fails to fill as required? Who pays the price? Moldflow analysis is an outstanding predictive engineering tool, a simulation tool which can identify potential problems or address uncertainty. Our scientific approach will save you both time and money.

Answers without wasting time or money!

Identifying part design issues

Reduce Ford engineering time

Optimizing gate size/location

Determine proper number of drops/gates

Evaluate hot runner designs/SVG

Define knit line locations

Cooling design recommendations

Reducing cycle times

Elimination of shrink fixtures

Identify cause of warpage

Minimize part warpage

Reduce tooling costs

Improve part quality

Elimination of costly trial & error methods

Providing Answers

To eliminate uncertainty and to ensure your design can be molded successfully, you need answers, answers before “cutting steel”. Our experience is a “must have” for those interested in reducing costs and optimizing productivity.

Certified & Experienced

Don’t leave your decision to chance!

Your last project… Did you have gating issues? Problems with cycle times or issues with part warpage? If your goal is to reduce molding costs, improve cycle times and identify potential part warpage, then consider our consulting services. Our track record is exceptional!

Have an application?

Call us at 630.761.9898 and let’s discuss how we can help you save money by “Getting it Right the 1st Time”.