Co-Injection Analysis

Using specialized or layered part materials can lead to many issues for the finished part: unless you do a co-injection analysis first! Our co-injection simulation and analysis tests the process of injecting a skin material first, following by a different core material. Knowing the thickness of each part material is a crucial step to designing and molding the best part possible, saving time, money, and effort in the process.

CAE Co-Injection Analysis helps to determine:

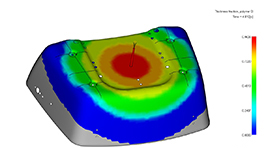

Thickness fraction of polymer B

shows what percentage of the wall is

occupied by the second polymer for

co-injection. This plot shows the

penetration about halfway

through the filling process.

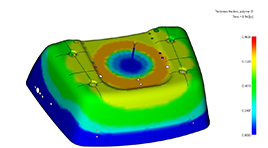

Thickness fraction of polymer B

shown at the end of injecting the

second polymer.

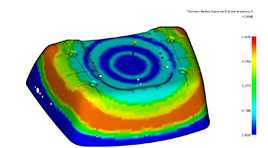

Thickness fraction of polymer B

shown at the end of injecting the

first polymer for the second time.

Consulting | Software | Training:

Improved Part Quality

Faster Cycle Times

Larger Processing Window

Less "Fire Fighting"

More Profit