Flow & Pack Analysis

Flow Analysis

Molding parts is already an expensive and time-consuming process. Why make it any harder? With our flow & pack analysis we’ll calculate the melt front advancement in the part from the injection location through the “switch-over” point to packing. By simulating this process – before production – we can identify and optimize the process to avoid molding uncertainty or to resolve an existing problem.

CAE Flow analysis evaluates or determine:

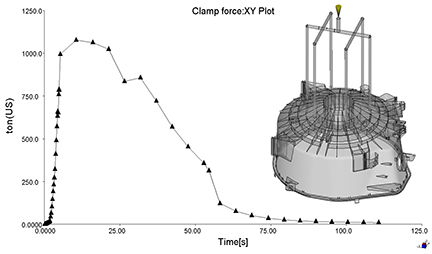

Packing Analysis

Once the flow analysis is complete, we conduct an equally important packing analysis. Additional material is injected into the cavity to compensate for the loss in volume as the material shrinks. The part is held under pressure while it solidifies.

CAE Packing analysis helps to determine:

Consulting | Software | Training:

Improved Part Quality

Faster Cycle Times

Larger Processing Window

Less "Fire Fighting"

More Profit