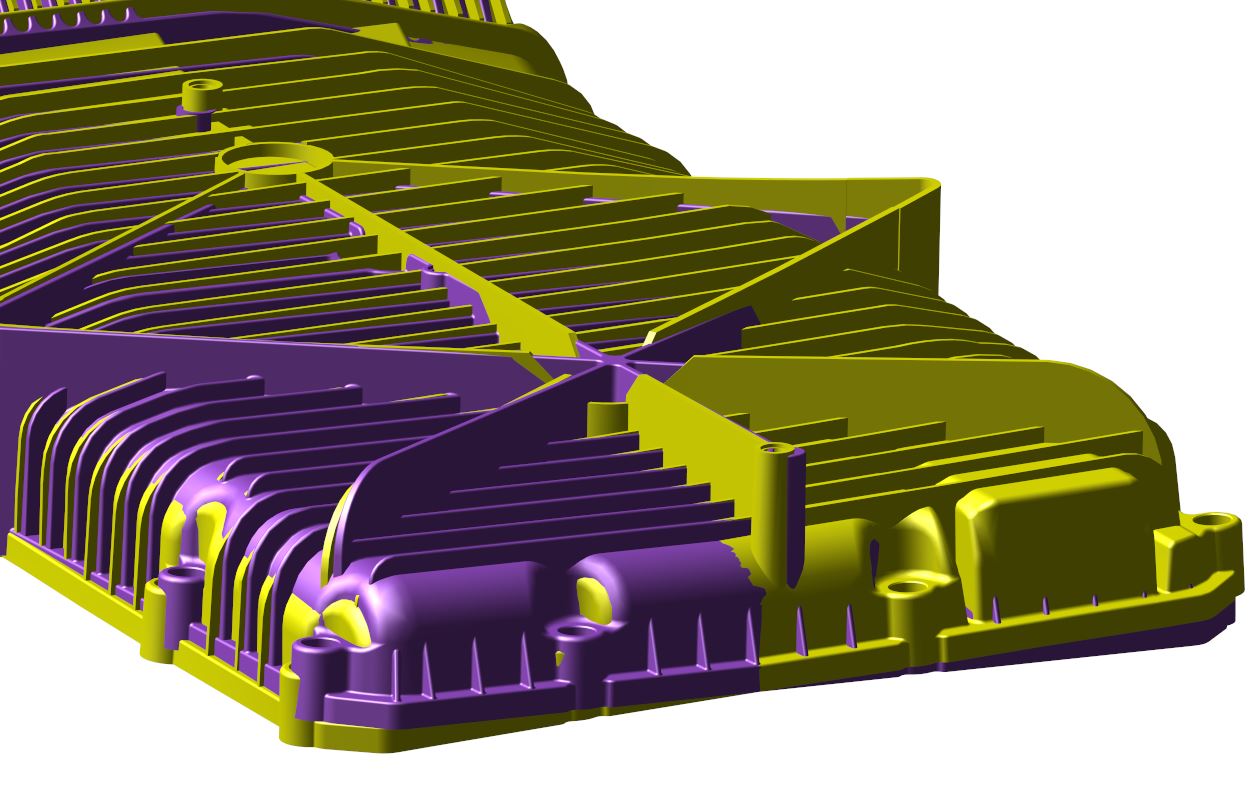

Windage + CAD Morphing

Windage allows you to bias your mold, whether you are off one way or another, to come back to center. Because you are doing some guess work with bringing the mold back to center, you may need to adjust a few times to accommodate your mold.

It is no surprise that the injection molding industry would use windage to describe adjustments made to a mold to account for warpage in a molded part. The way it works for molding is as follows:

1. Mold parts.

2. Let them settle one or two days.

3. Measure the warpage in critical areas.

4. Reverse-bias the mold in those critical areas.

5. Repeat Step 1 until critical dimensions are within tolerances.

It is that last step that is the kicker. How many tuning loops will be required to get the parts where you want them? The answer to that question will dictate how much time and money will be required to solve the problem.

Consider that each time a tuning loop is completed, there are shipping costs, resin costs and costs from the moldmaker. Time lost is also a concern. Time to make the mold changes, shipping time and mold trials are all things that eat into the time required to get the part into production. If you are a moldmaker, you want to use your experience to be part of the solution. Experience is a great teacher, but it can only get you so far when it comes to putting windage into your tools.

This is where warpage simulation comes into play. Warpage analysis allows you to make windage adjustments to the shape of the mold without actually cutting steel. Determining how much windage to use is very tricky—whether you are doing it with or without the help of simulation—because the temptation is to reverse-bias the mold by the same amount the part warped in the first place.

Applying windage to a mold is not for the faint of heart. However, if a warpage problem cannot be solved through simulation to improve the mold design or process, then windage may be the last resort. If warpage simulation is conducted properly by experienced simulation engineers, it can be leveraged to take the guesswork out of windage, and reduce or even eliminate the tuning loops needed to bring parts into tolerance. Indeed, the sun shines bright on my Old Kentucky Windage.

Tight tolerance concerns?

Get it Right the 1st Time.

Consulting | Software | Training:

Improved Part Quality

Faster Cycle Times

Larger Processing Window

Less "Fire Fighting"

More Profit