Just about everyone in the plastics injection molding industry has either heard of flow analysis, or seen it done. We’ve all heard it generically referred to as a moldflow. “Let’s get a moldflow done”, or “What did the moldflow say?” are things you may have heard on any given project.

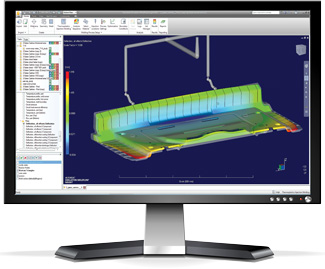

Well, what exactly is a moldflow? Most people refer to it as a computer simulation performed to predict the flow of plastic in an injection mold, which can be used to make mold design decisions, or to solve an existing molding problem. But did you know that a moldflow can actually simulate much more than that? Moldflow simulation can predict all phases of the injection molding process, including flow, pack, and cooling. It can even predict the warped shape of the part based on all of those inputs from the process. Not only that, but other types of simulation can be done – thermoset, co-injection, injection-compression, gas assist, and two-shot.

Getting a Moldflow analysis performed has helped thousands of OEMs, Moldmakers, Molders, and Part Designers produce thousands of better quality injection molded parts more efficiently. Just be sure to have your projects handled by Experienced/Certified Moldflow Analysts in order to receive the most accurate results from the software.