CAE Services Corporation

280 Belleview Lane

Batavia, IL 60510

630.761.9898

www.caeservices.com

FOR IMMEDIATE RELEASE

Contact: Mark Solberg

mark@caeservices.com

CAE Services becomes primary reseller of AutoDesk® Moldflow® simulation software

Partnership between two leaders in moldflow simulation solutions benefits customers

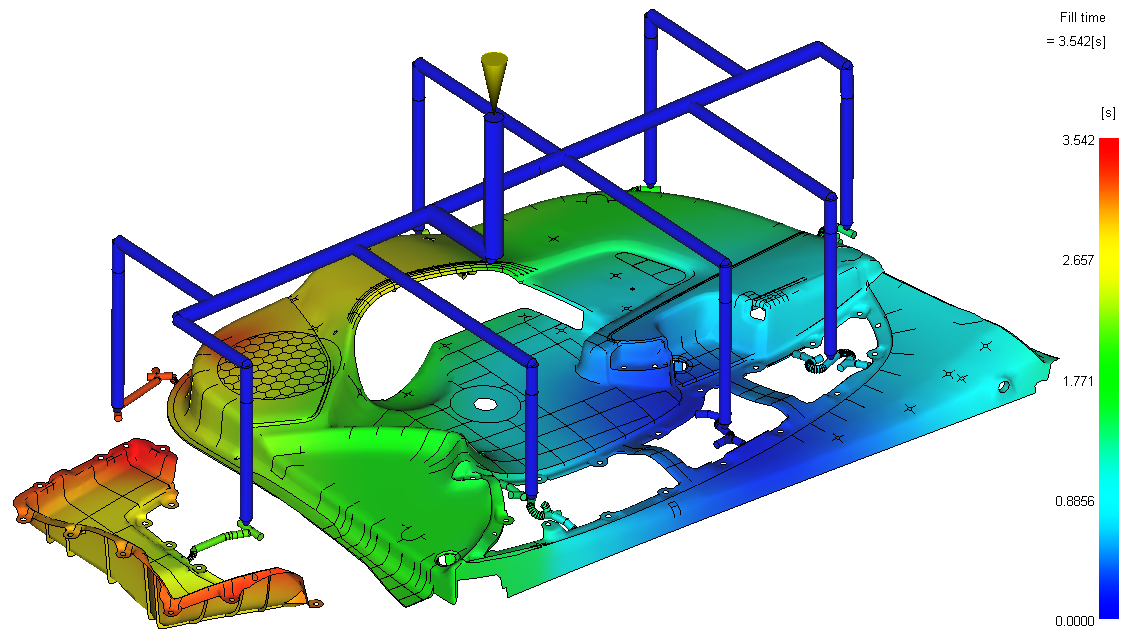

Batavia, IL (October 24, 2019) – CAE Services Corporation (caeservices.com) is proud to announce a unique partnership with the premier moldflow simulation software company in the world, AutoDesk® (autodesk.com). Combined, CAE and AutoDesk will provide Moldflow® simulation software to molders, part designers, OEMs, tool suppliers, and hot runners to help them analyze, identify, and solve injection molding issues to save time and money.

CAE will be the primary reseller of AutoDesk Moldflow simulation software in North America.

“As experts in the field of moldflow simulation consulting, software, and training, we’re proud to partner with AutoDesk,” said Mark Solberg, executive vice president for sales and marketing. “Being able to leverage our expertise from over 24,000 projects with the industry-standard in simulation software will help us serve our clients better and make them more profitable.”

AutoDesk offers a suite of moldflow simulation and project reporting software packages in different levels. The following is a partial features list:

- MoldFlow Adviser Premium – Part feasibility, gate location evaluation, analysis, etc.

- MoldFlow Adviser Ultimate – Premium plus filling, packing, and cooling guidance, runner balance, etc.

- MoldFlow Insight Standard – in-depth simulation, 2-shot over molding, SVG, etc.

- MoldFlow Insight Premium – Standard plus simultaneous solving capacity, conformal cooling, DOE, etc.

- MoldFlow Insight Ultimate – Premium plus specialized molding simulations (CBA, gas assist, PIM, etc.)

“The different levels of performance, in addition to our different levels of consulting and training services provides a great package deal for our customers,” added Solberg. “Training is an essential part in using any software product successfully, that’s why we offer fundamentals classes for our experts to train more experts. It’s a perfect tandem.”

CAE is available to offer moldflow consulting, software, and training services throughout the United States, Canada, and select overseas locations by calling +1.630.761.9898 or by visiting caeservices.com.

About CAE

Since 1988, CAE Services has developed a unique process and expert reputation in the moldflow simulation, consulting, software, and training industry. With the largest Expert Certified moldflow simulation and analysis team in North America and over 24,000 individual projects completed (and counting!), CAE has been at the forefront of helping customers across the country and around the world, save time, money, and become more profitable.

###

CAE Services Corporation

280 Belleview Lane

Batavia, IL 60510

Phone: 630.761.9898

Web: caeservices.com

Thinking of Buying Software?

Thinking of Buying Software?