Ask The Moldflow Experts

Appearance Issues in Moldflow

Ask The Moldflow Experts Webinar Topic:

Appearance Issues in Moldflow

November 30th, 2021 | 12:30 PM CDT

One of the most time-consuming and frustrating things about injection molding can be chasing appearance issues after all of the efforts that go into engineering the part and mold. Join our webinar to see how CAE Services’ Experts solve appearance problems and plan to avoid them in the first place.

- Learn different approaches to solving/avoiding knit lines in your part;

- Learn how part design and gate locations can affect the formation of air traps;

- Learn how to size gates properly to avoid gate blush;

- Discover the causes of sink marks and how to avoid them;

- In-depth topic discussion with questions fielded during the presentation + Q&A at the end of the webinar

ATME - Take Away

Knit Lines

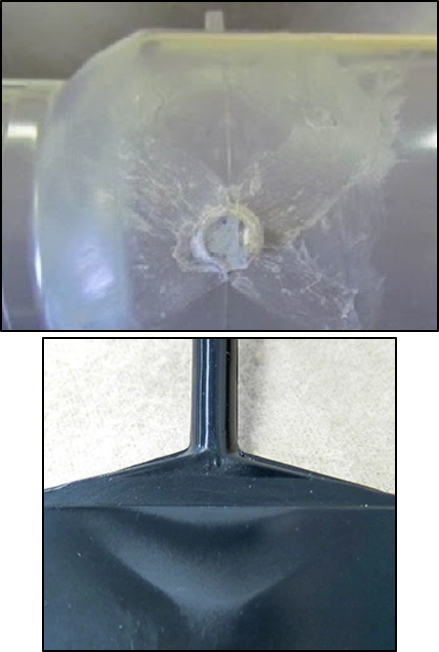

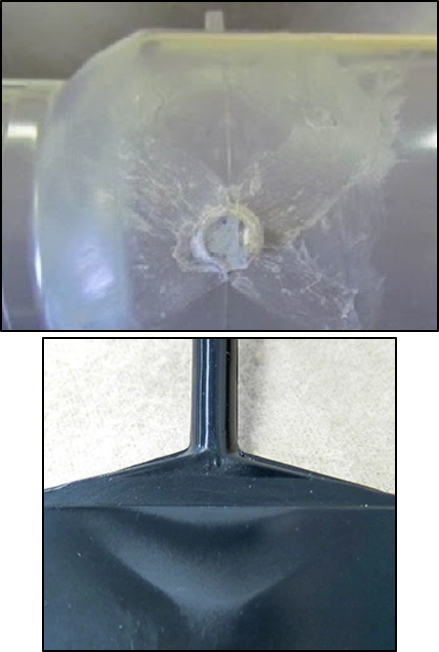

The Problem

-

Blemish that occurs from the collision of two flow fronts

-

Reduces strength

-

Unsightly appearance

-

Often unavoidable due to geometry features

-

Holes

-

Tall standing cores

-

The Solution

-

Parts with holes will have knit lines

-

Mold part with hole filled and punch/machine the hole

-

Place knit line in acceptable area

-

-

Move gate?

-

If you’re lucky

-

-

Re-sequence the flow

-

If you have valve gates

-

-

Modify the part design

-

Flow leaders/restrictors

-

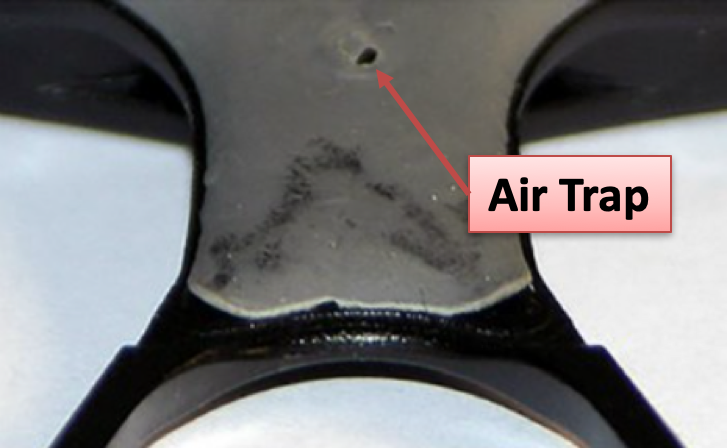

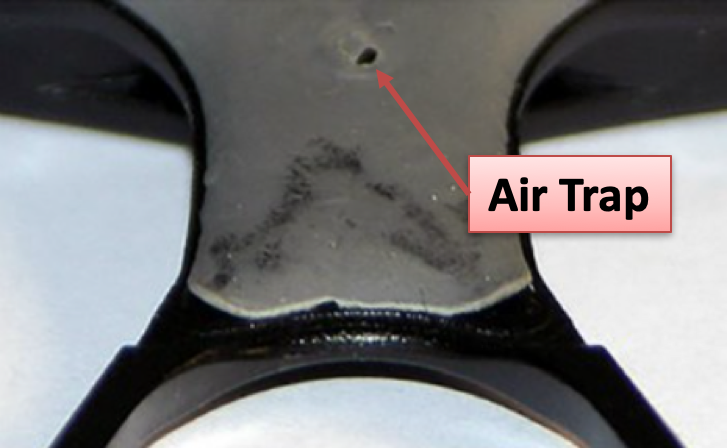

Air Traps

The Problem

-

Air that occupies the mold must get out as plastic flows

-

Supposed to be through vents

-

Part design/gate position can produce backfilling/racetracking

-

Non-fills or burned material

-

Compressed air pushes back on melt front

-

Compressed air = temp increase

-

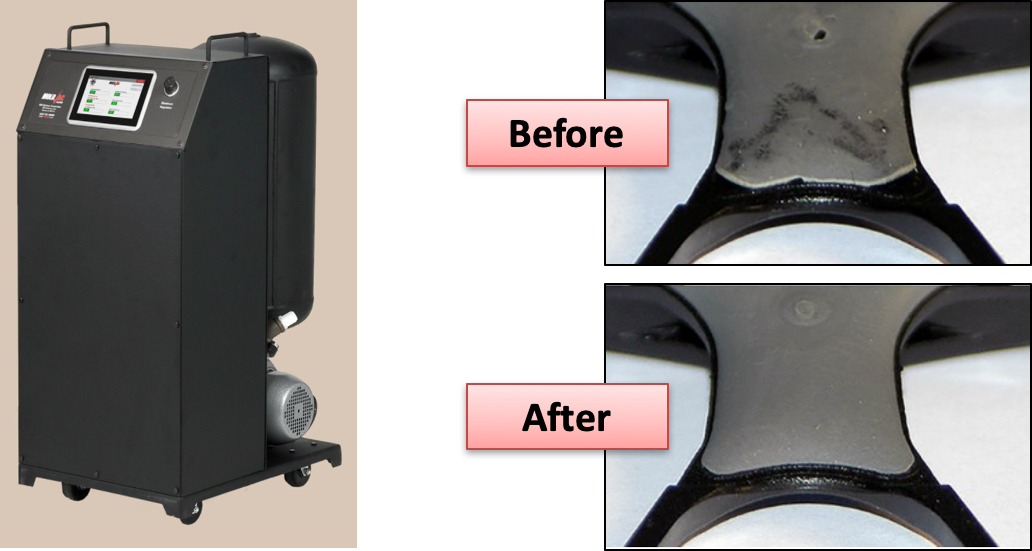

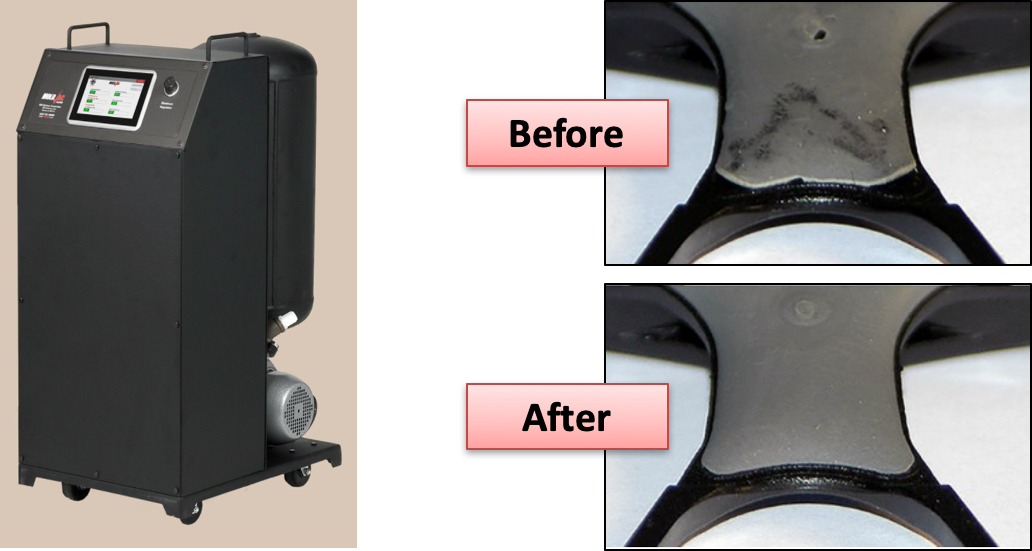

The Solution

Existing tool - Faster filling

Existing tool - vacuum venting

Existing tool - Part Design Change

-

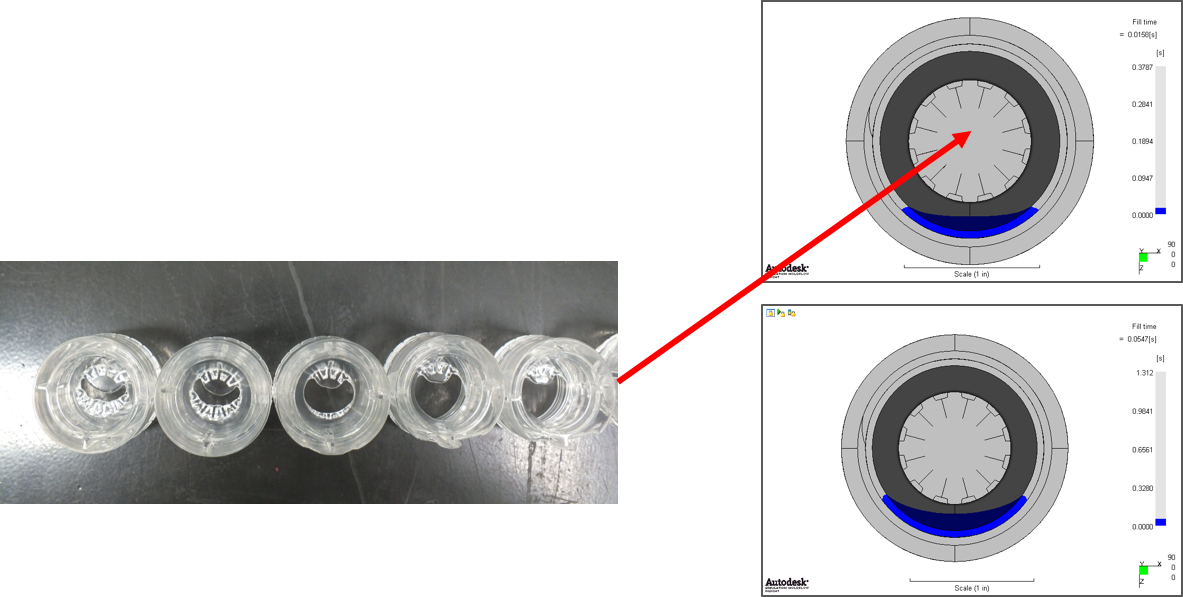

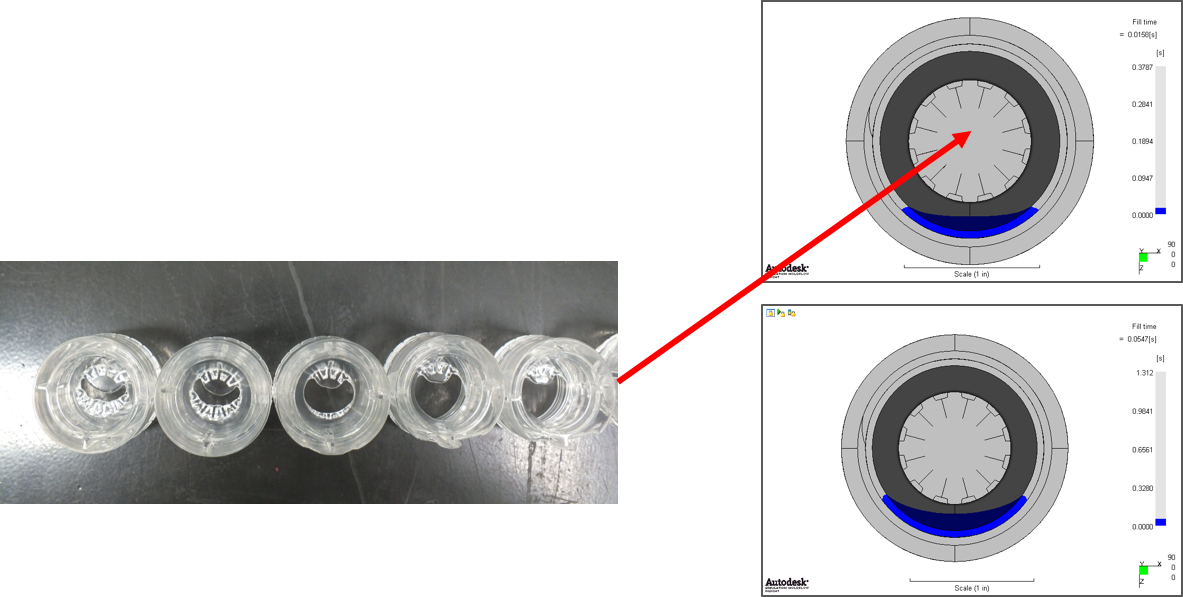

Air trap in optical area was unacceptable

-

Increased wall thickness in optical area

-

Air trap moved to acceptable area

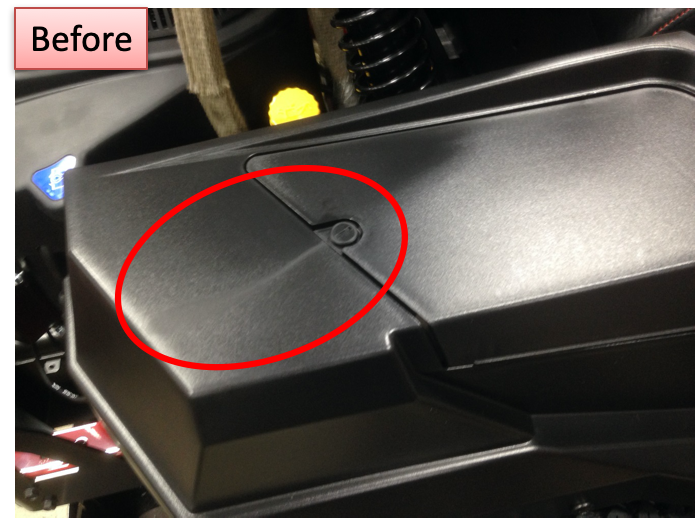

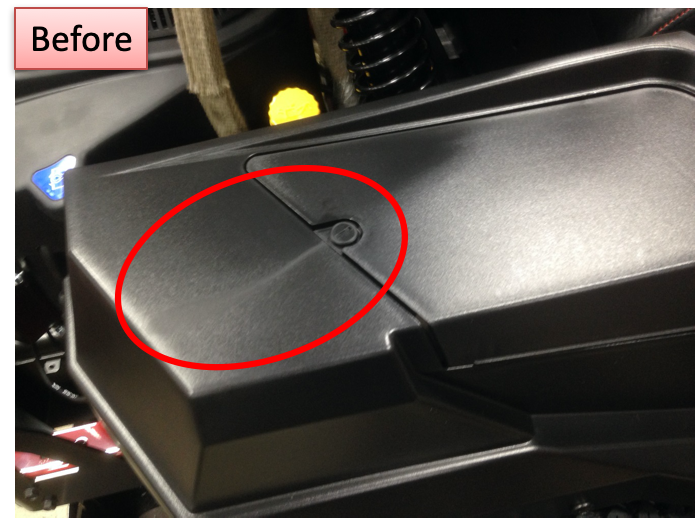

Sink Marks

The Problem

-

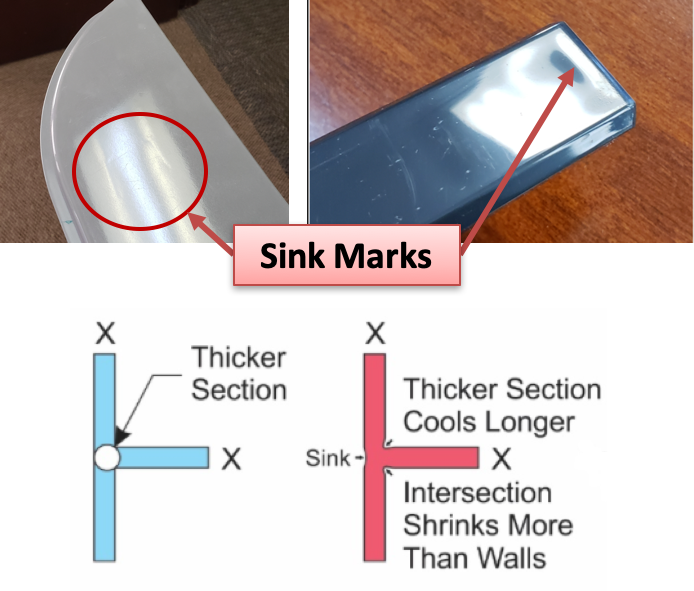

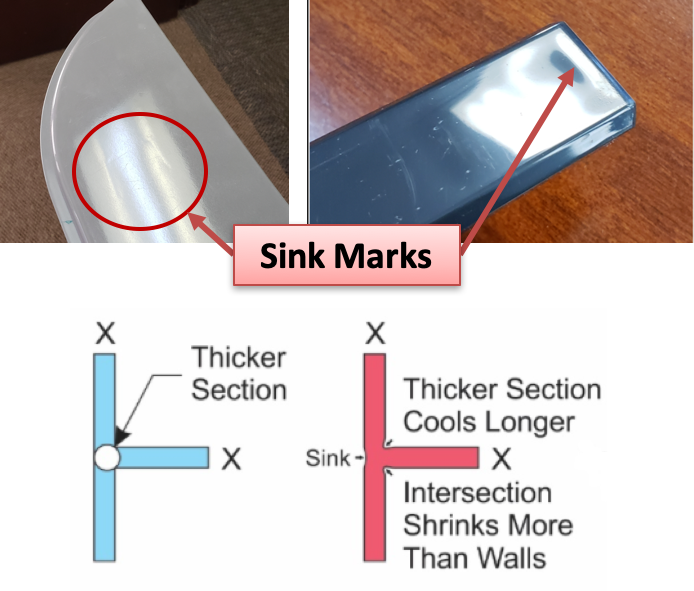

Depression at the surface where back side features intersect

-

Sometimes in very thick sections

-

Caused by excessive shrinkage

-

Thicker section

-

Farther from gate

-

Higher temp

-

Higher shrink materials

-

Beware of corners!

-

The Solution

Existing tool - improving sink

-

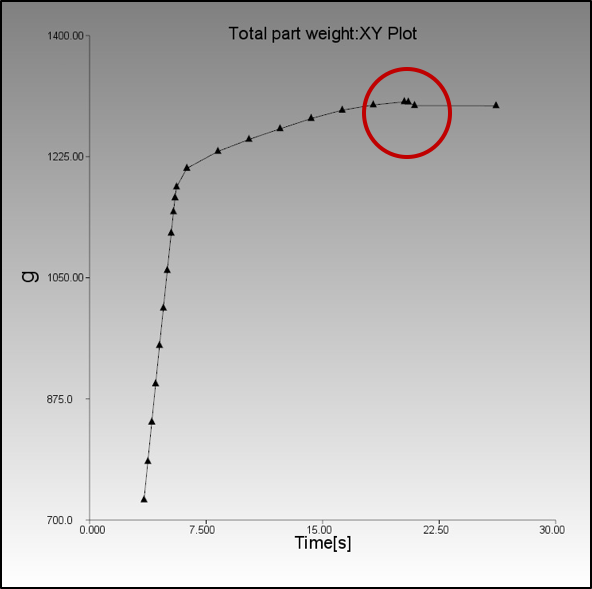

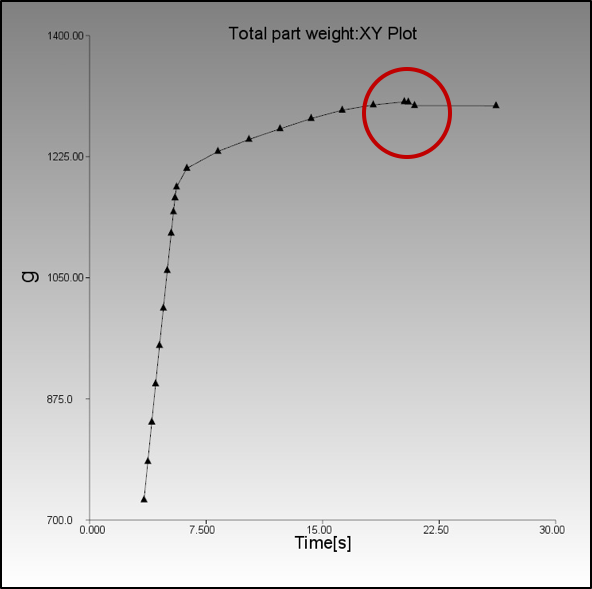

Do a gate freeze study

-

Reduce rib/wall ratio

-

Welding involved

-

-

Increase pack pressure

-

Increases clamp force requirement

-

-

Move gate(s)

-

May not be possible

-

May cause unintended consequences

-

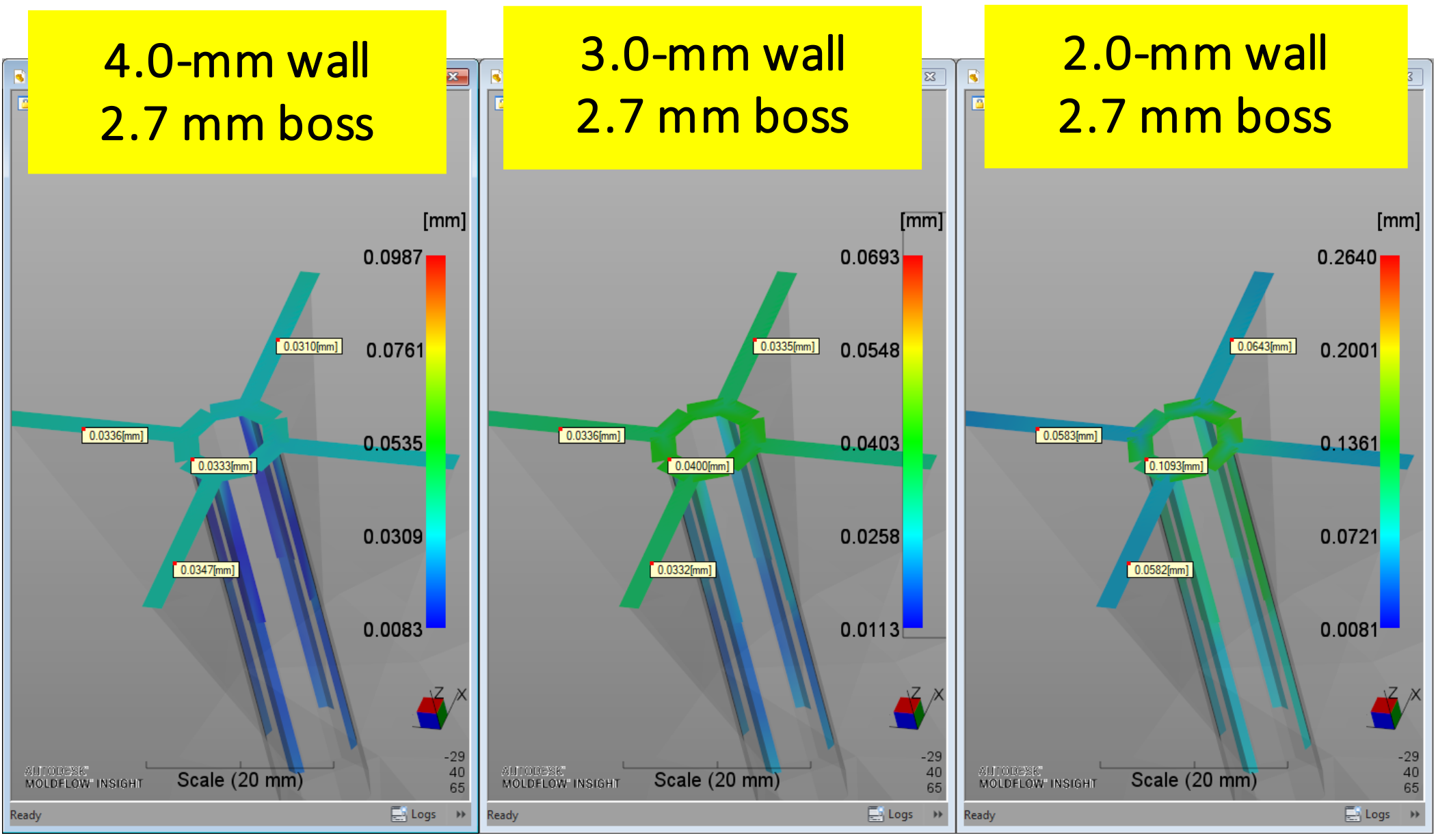

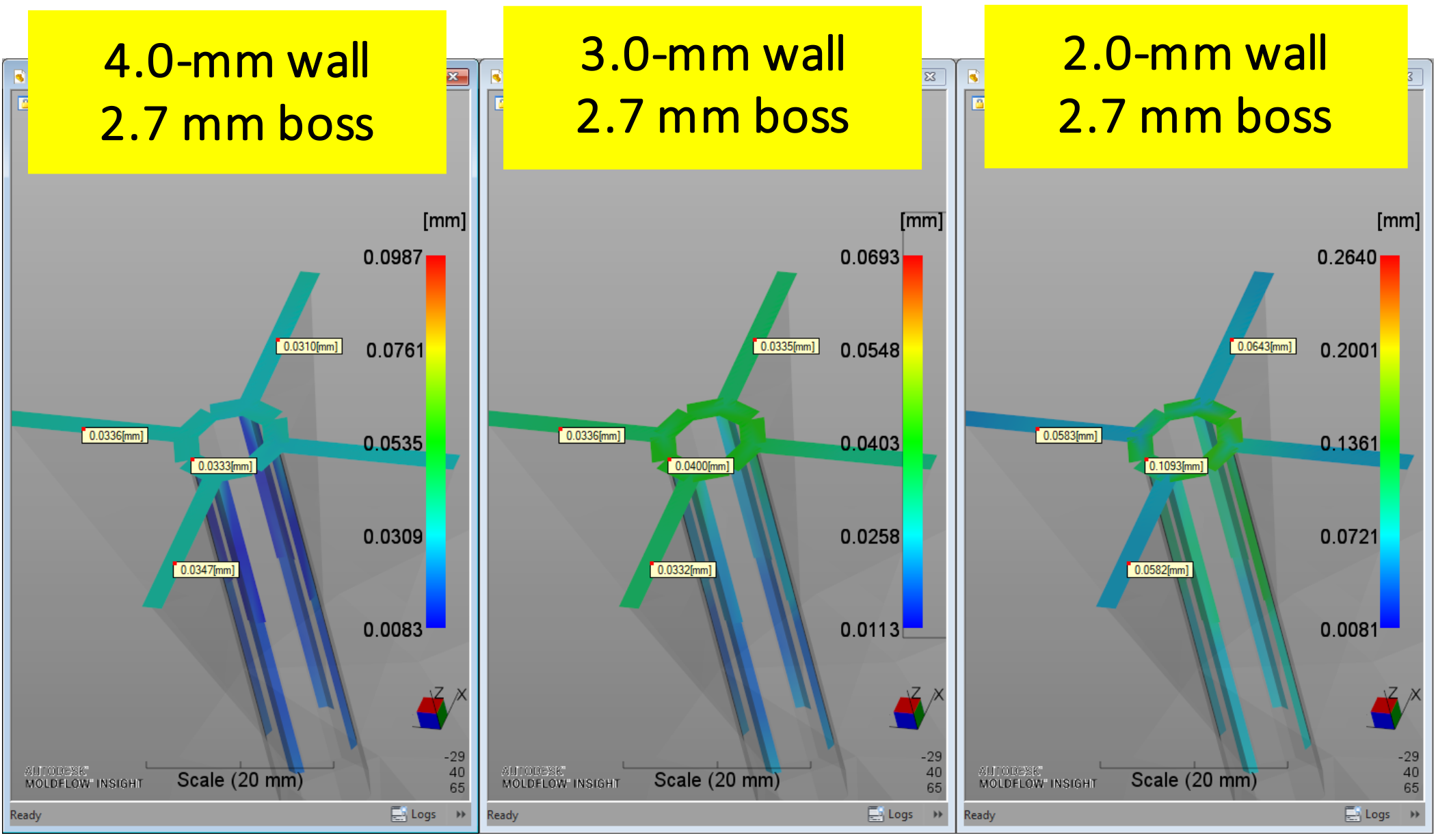

new tool - use simulation results

-

Reduce rib/wall ratio

-

No welding involved

-

Use sink savers?

-

Beware of short shots

-

-

Move gate(s)

-

Closer to areas of sink

-

-

Sink Depth Results

-

Keep below 0.1 mm

-

Below 0.025 mm for glossy finishes

-

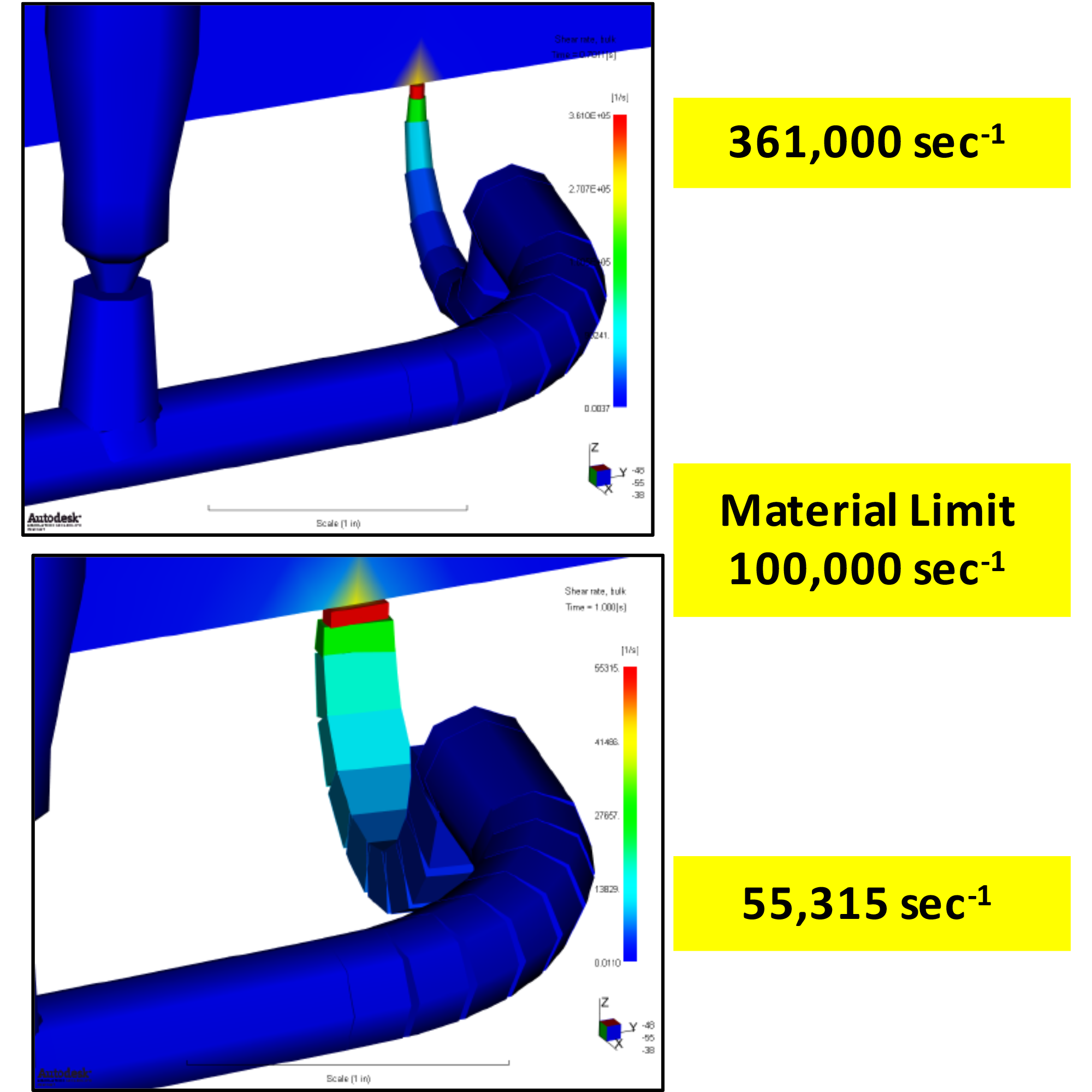

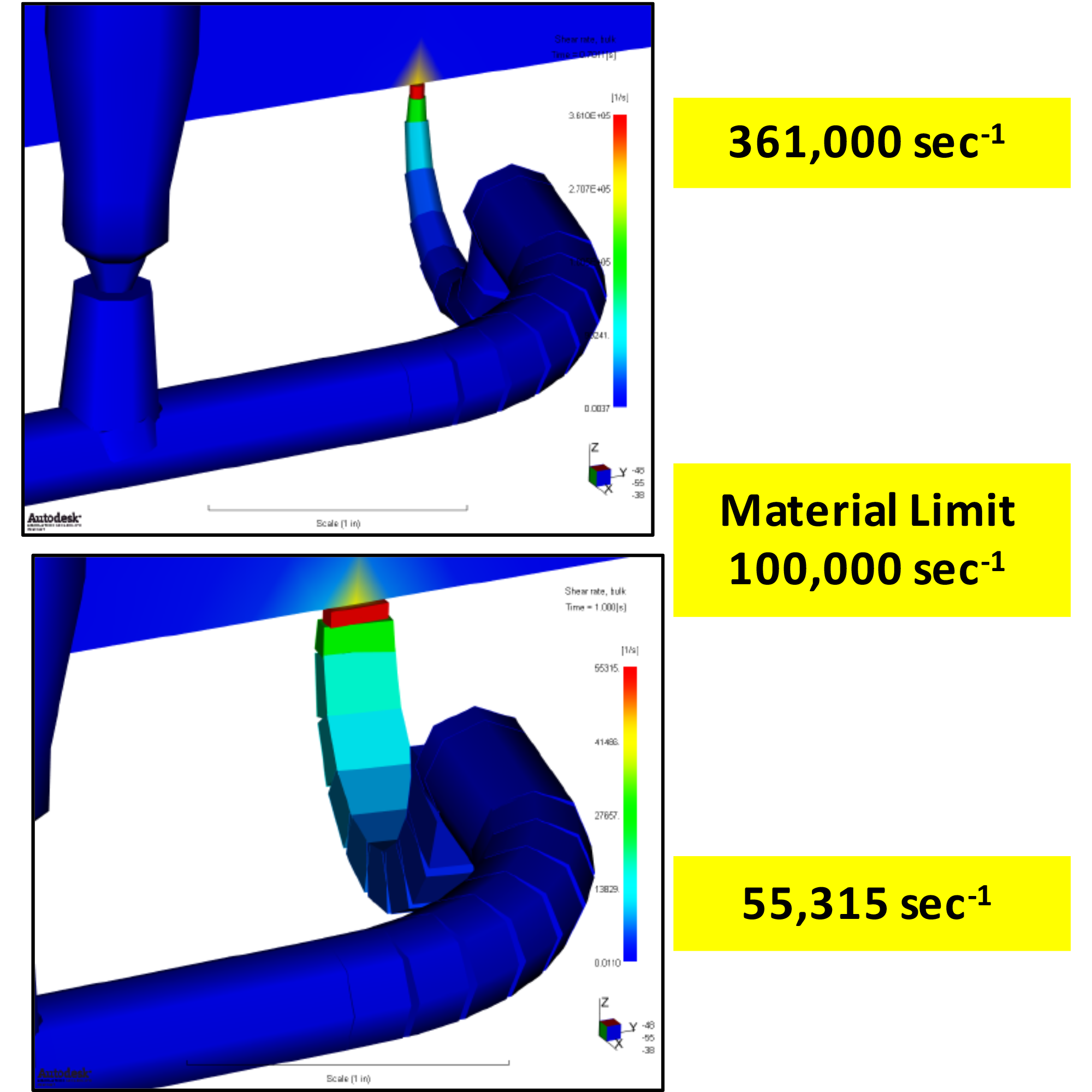

Blush

The Problem

gate blush

-

Blemish extending from the gate

-

Caused by material degradation

-

Excessive shearing breaks molecular chains

-

Thin gates

-

Too few gates

-

Fill rate too fast

-

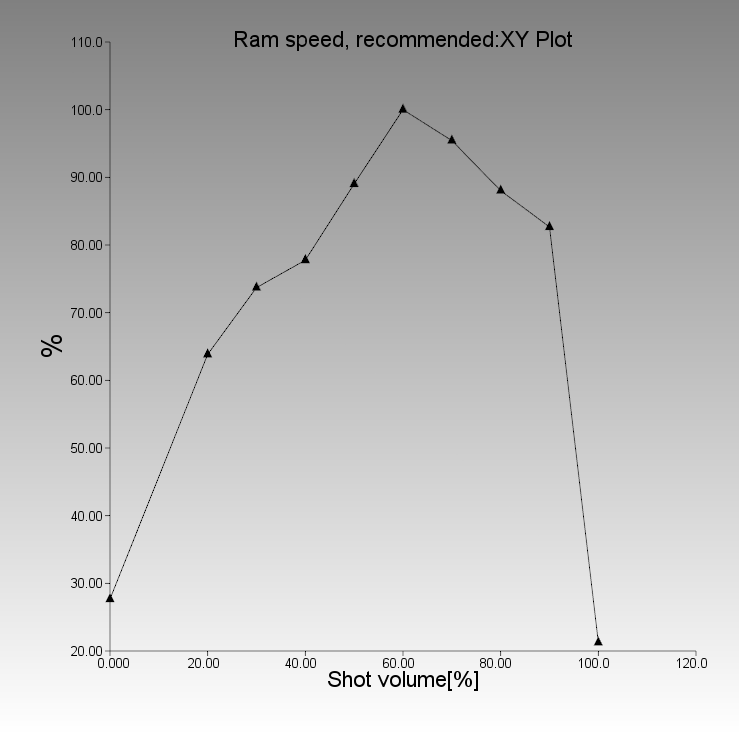

The Solution

Existing tool - improving gate blush

-

Slow down fill speed

-

May cause unintended consequences

-

-

Increase gate size

-

May be undesirable

-

May cause sink near gate area

-

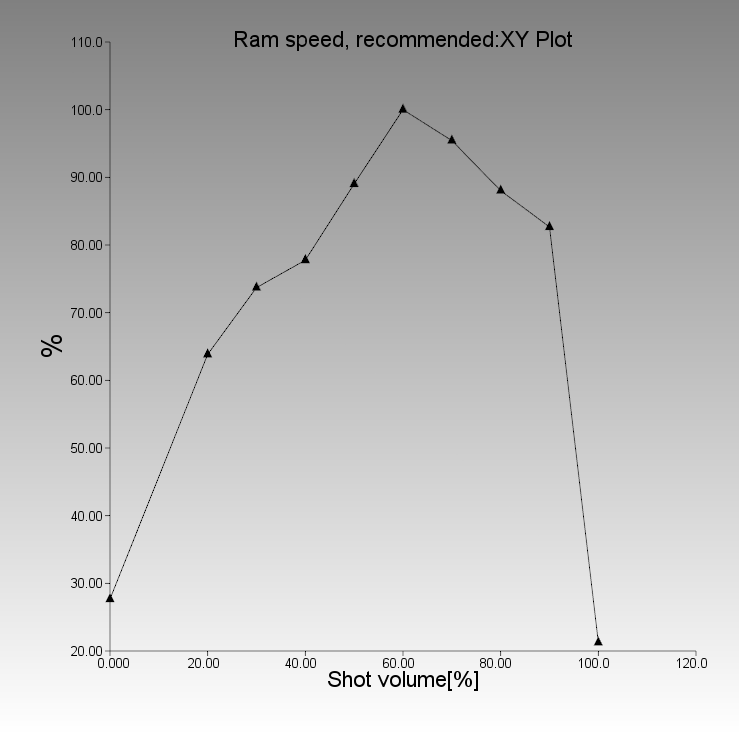

new tool - use simulation results

-

Ensure proper number of gates

-

Increase gate size

-

Use ram-speed profiling

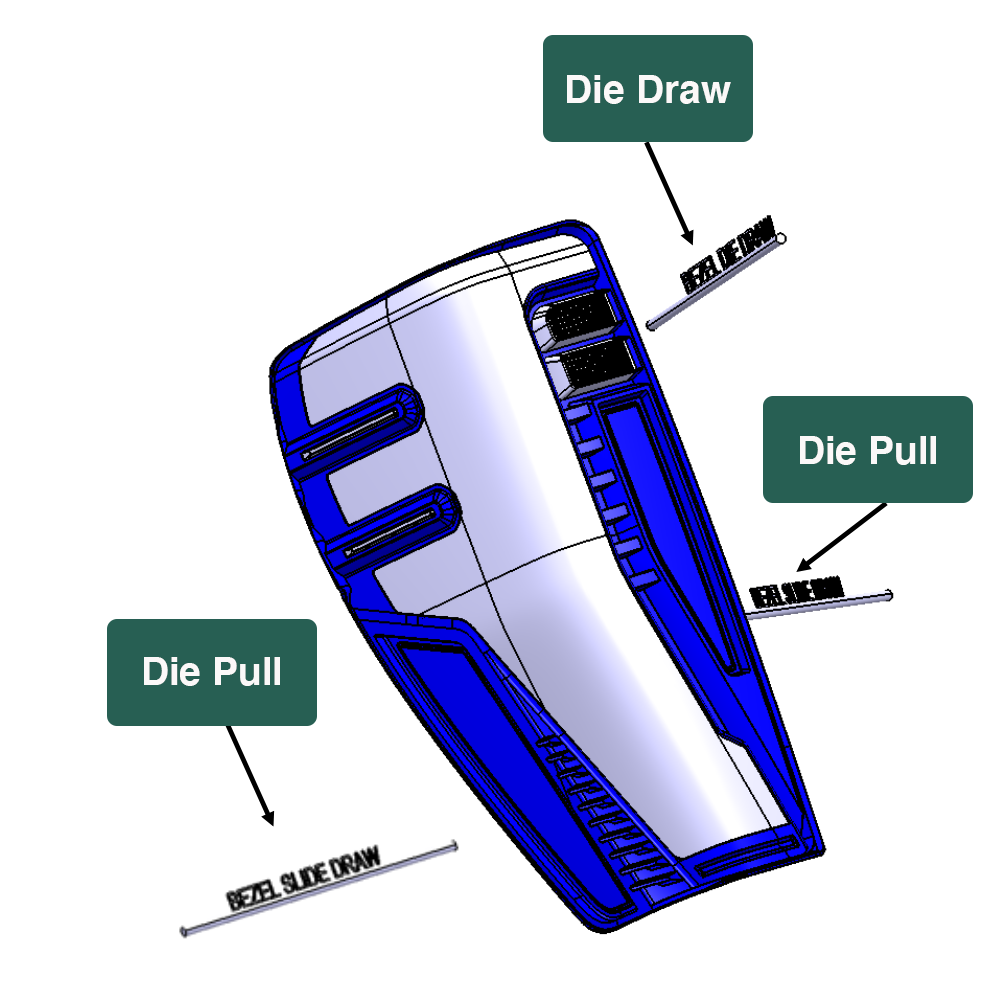

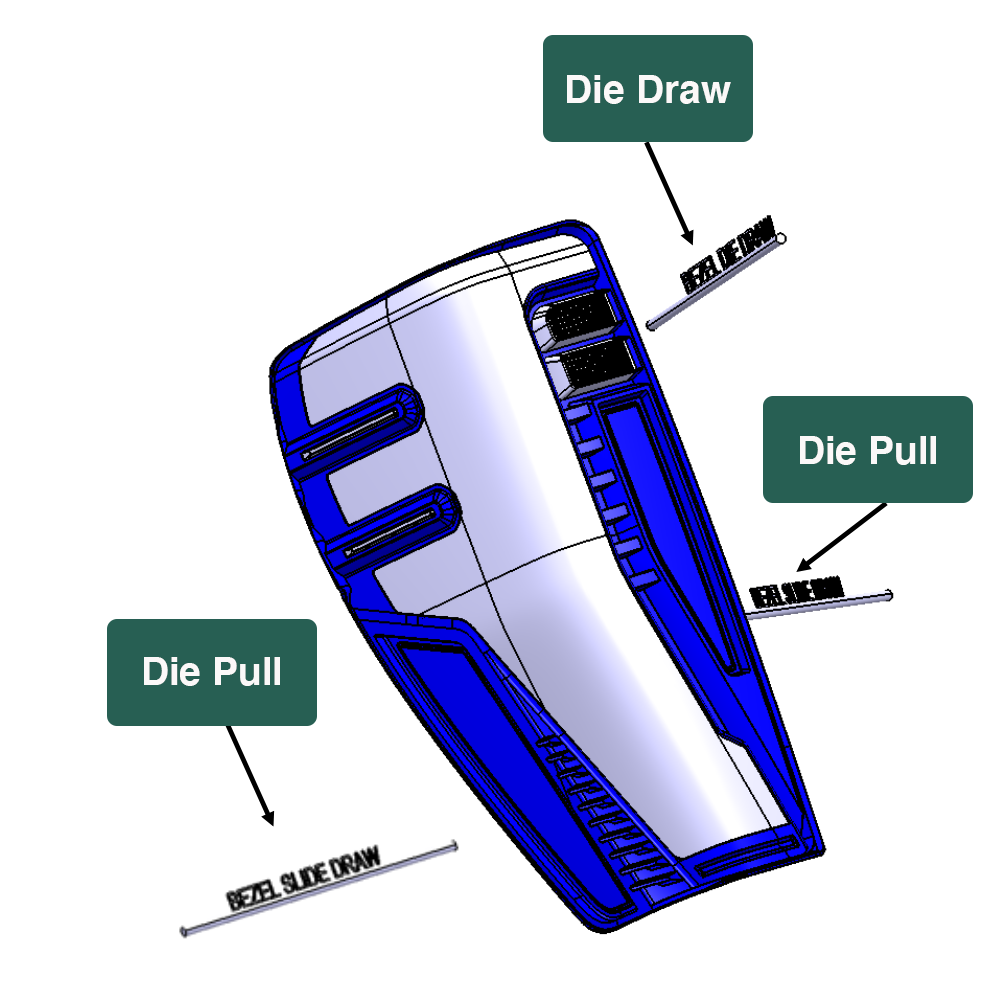

Make sure part is "feased"

-

Preliminary Feasibility Study Assures:

-

Part is good for tooling

-

Sufficient side wall draft

-

Rib-to-wall ratio

-

Proper fit/function

-

Basic die draw, die pull directions identified

-

Some Parting Thoughts

-

Use simulation upfront before mold is built

-

Try to hardwire solutions into part or mold design

-

Use Expert Moldflow engineers

-

Expertise helps us know when results are reasonable

-

Material Data

-

Mesh

-

Know how to:

-

Identify causes

-

Solve Problems

-

Mold/Part Design

-

Process to fix aesthetics

-

-

-

Appearance Issues in Moldflow

Ask The Moldflow Experts Webinar Topic:

Appearance Issues in Moldflow

November 30th, 2021 | 12:30 PM CDT

One of the most time-consuming and frustrating things about injection molding can be chasing appearance issues after all of the efforts that go into engineering the part and mold. Join our webinar to see how CAE Services’ Experts solve appearance problems and plan to avoid them in the first place.

Learn different approaches to solving/avoiding knit lines in your part;

Learn how part design and gate locations can affect the formation of air traps;

Learn how to size gates properly to avoid gate blush;

Discover the causes of sink marks and how to avoid them;

In-depth topic discussion with questions fielded during the presentation + Q&A at the end of the webinar

ATME – Take Away

If you are experiencing appearance issues:

Email Us Today!

#id-4011 .carousel-slider-nav-icon {

fill: #f1f1f1

}

#id-4011 .carousel-slider-nav-icon:hover {

fill: #00d1b2

}

#id-4011 .owl-prev,

#id-4011 .owl-next,

#id-4011 .carousel-slider-nav-icon {

height: 48px;

width: 48px

}

#id-4011.arrows-outside .owl-prev {

left: -48px

}

#id-4011.arrows-outside .owl-next {

right: -48px

}

#id-4011 .owl-dots .owl-dot span {

background-color: #f1f1f1;

width: 10px;

height: 10px;

}

#id-4011 .owl-dots .owl-dot.active span,

#id-4011 .owl-dots .owl-dot:hover span {

background-color: #00d1b2

}

Knit Lines

The Problem

Blemish that occurs from the collision of two flow fronts

Reduces strength

Unsightly appearance

Often unavoidable due to geometry features

Holes

Tall standing cores

The Solution

Parts with holes will have knit lines

Mold part with hole filled and punch/machine the hole

Place knit line in acceptable area

Move gate?

If you’re lucky

Re-sequence the flow

If you have valve gates

Modify the part design

Flow leaders/restrictors

Air Traps

The Problem

Air that occupies the mold must get out as plastic flows

Supposed to be through vents

Part design/gate position can produce backfilling/racetracking

Non-fills or burned material

Compressed air pushes back on melt front

Compressed air = temp increase

The Solution

Existing tool – Faster filling

Existing tool – vacuum venting

Existing tool – Part Design Change

Air trap in optical area was unacceptable

Increased wall thickness in optical area

Air trap moved to acceptable area

Sink Marks

The Problem

Depression at the surface where back side features intersect

Sometimes in very thick sections

Caused by excessive shrinkage

Thicker section

Farther from gate

Higher temp

Higher shrink materials

Beware of corners!

The Solution

Existing tool – improving sink

Do a gate freeze study

Reduce rib/wall ratio

Welding involved

Increase pack pressure

Increases clamp force requirement

Move gate(s)

May not be possible

May cause unintended consequences

new tool – use simulation results

Reduce rib/wall ratio

No welding involved

Use sink savers?

Beware of short shots

Move gate(s)

Closer to areas of sink

Sink Depth Results

Keep below 0.1 mm

Below 0.025 mm for glossy finishes

Blush

The Problem

gate blush

Blemish extending from the gate

Caused by material degradation

Excessive shearing breaks molecular chains

Thin gates

Too few gates

Fill rate too fast

The Solution

Existing tool – improving gate blush

Slow down fill speed

May cause unintended consequences

Increase gate size

May be undesirable

May cause sink near gate area

new tool – use simulation results

Ensure proper number of gates

Increase gate size

Use ram-speed profiling

Make sure part is “feased”

Preliminary Feasibility Study Assures:

Part is good for tooling

Sufficient side wall draft

Rib-to-wall ratio

Proper fit/function

Basic die draw, die pull directions identified

Some Parting Thoughts

Use simulation upfront before mold is built

Try to hardwire solutions into part or mold design

Use Expert Moldflow engineers

Expertise helps us know when results are reasonable

Material Data

Mesh

Know how to:

Identify causes

Solve Problems

Mold/Part Design

Process to fix aesthetics