Ask The Moldflow Experts

Understanding GM's Moldflow Requirements

Ask The Moldflow Experts Webinar Topic:

Understanding GM's Moldflow Requirements

August 17th, 2021 | 12:30 PM CDT

- Why these standards are necessary

- Personnel required

- 5 Phases of Moldflow

- Reporting requirements

- Personnel required

- At the press – detailed procedures

- Filling out the Moldflow Scorecard

- How to make it work!

ATME - Take Away

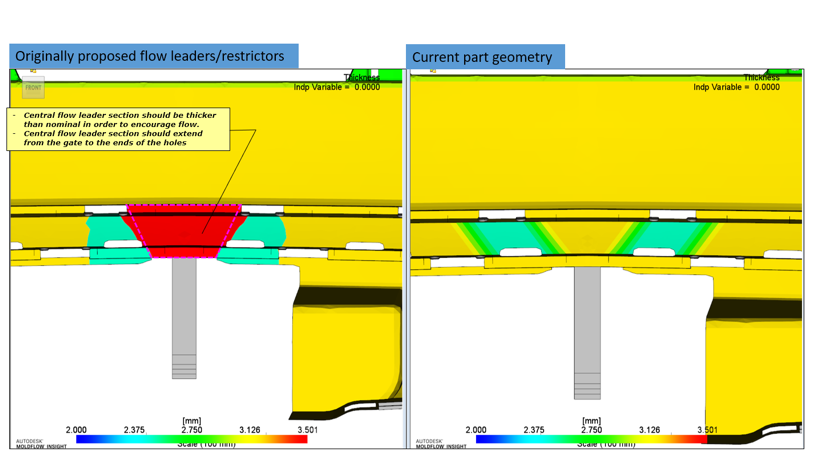

Benefits of GM Moldflow Standards

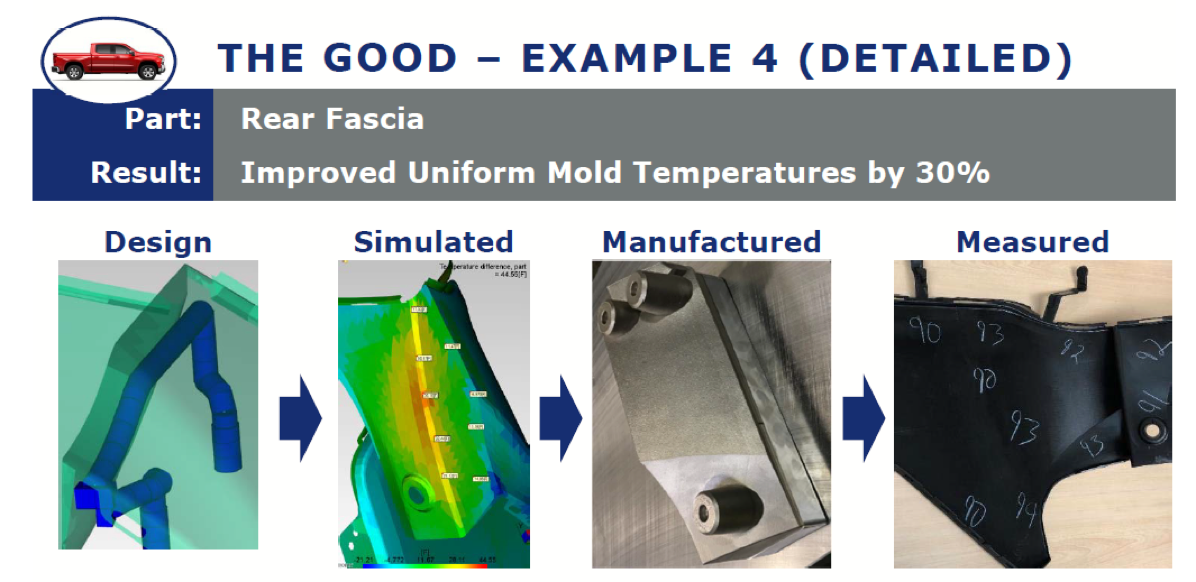

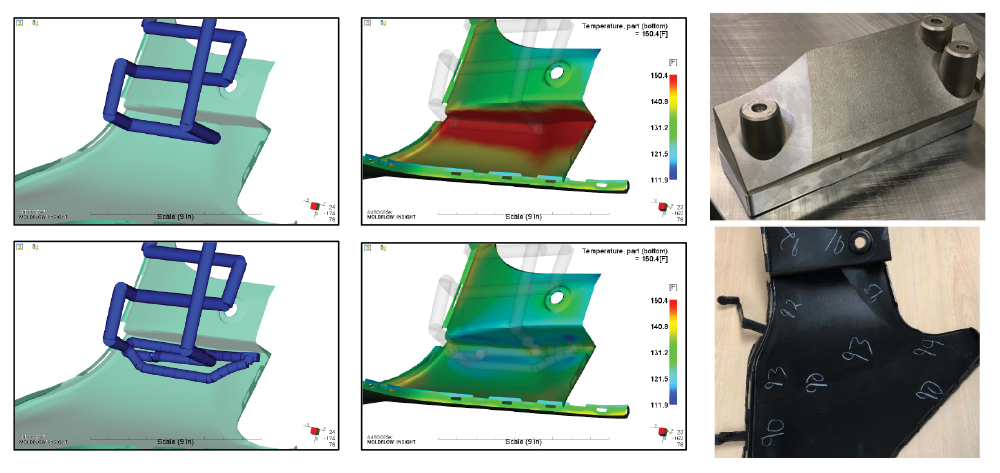

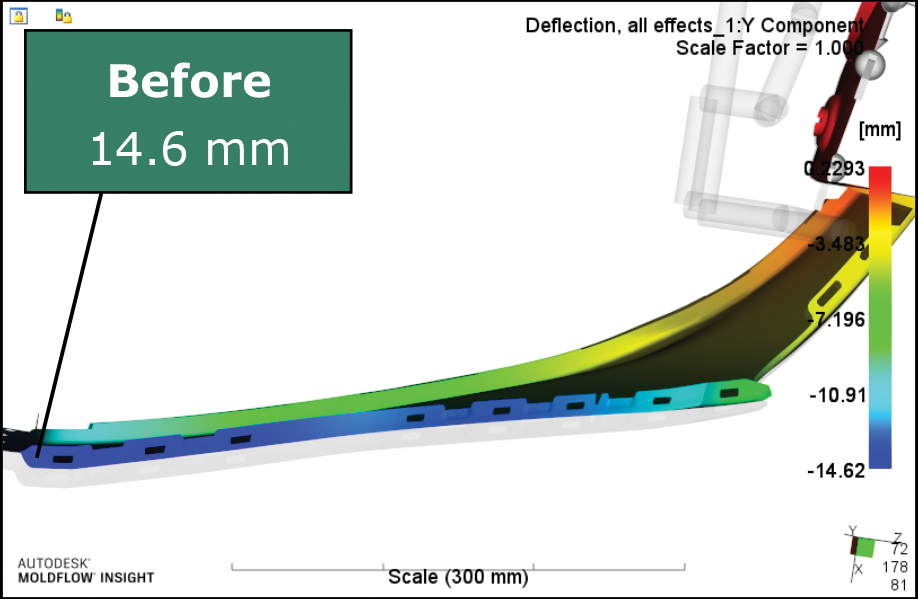

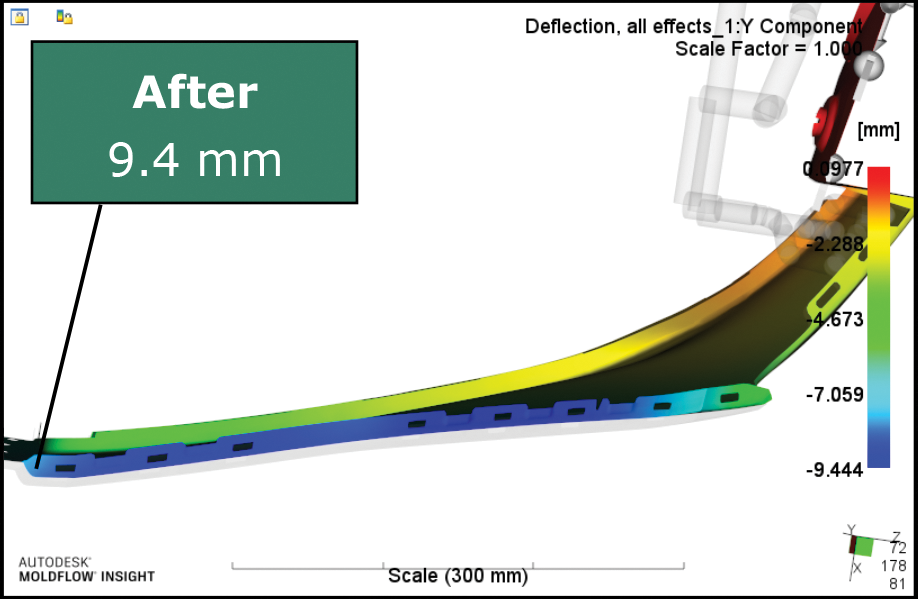

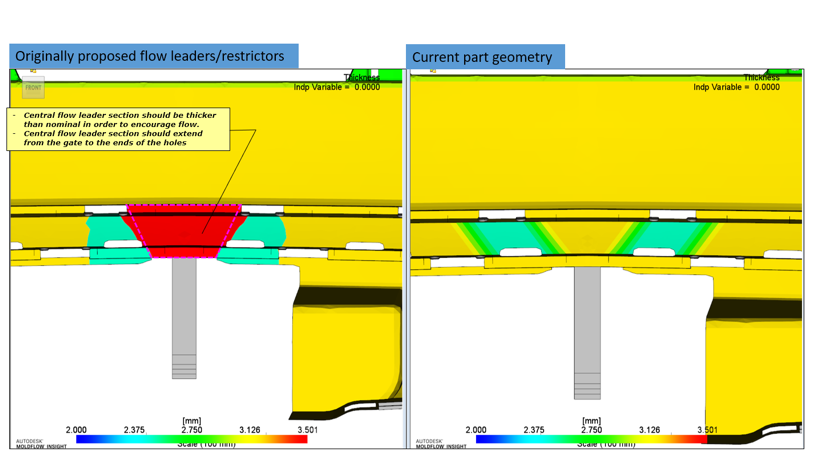

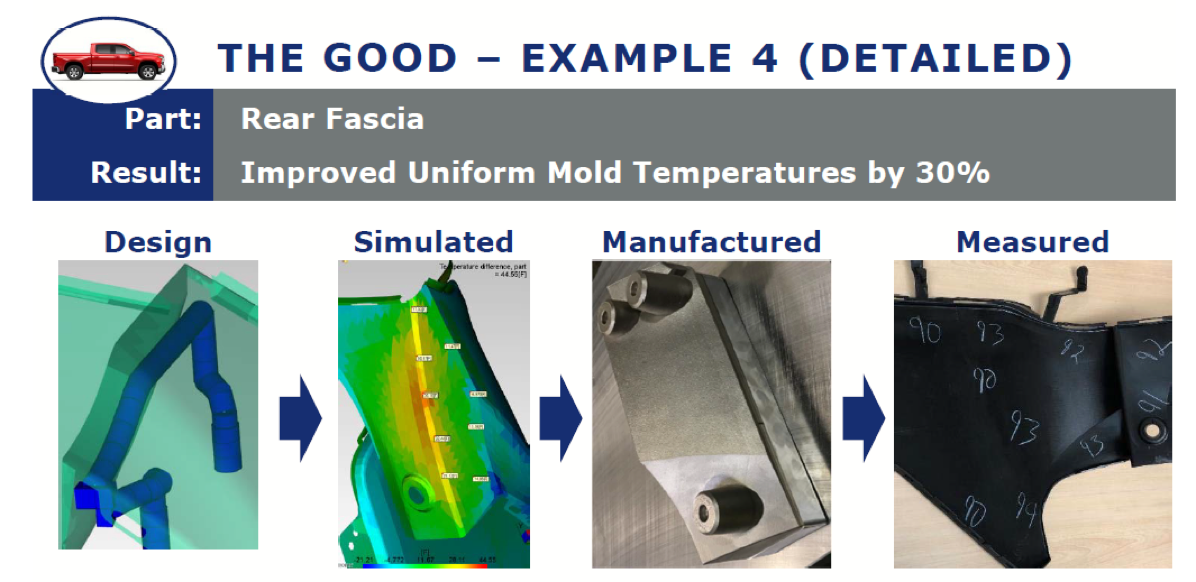

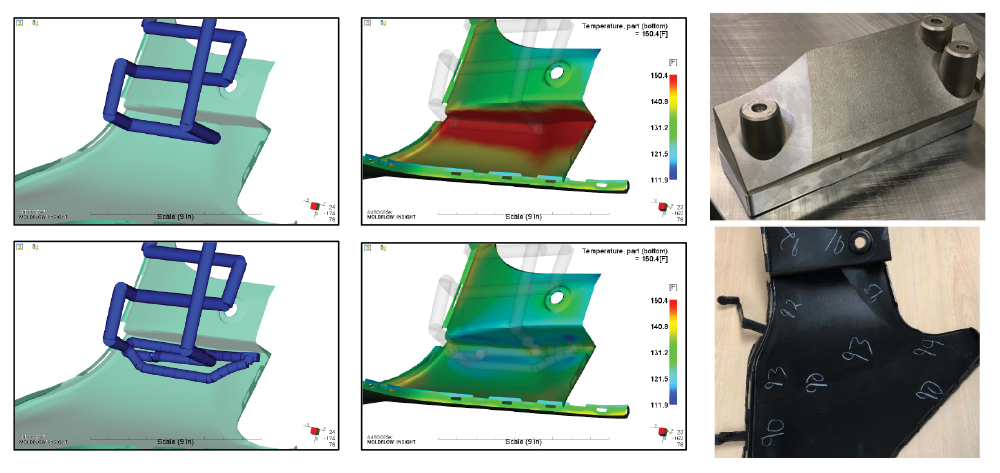

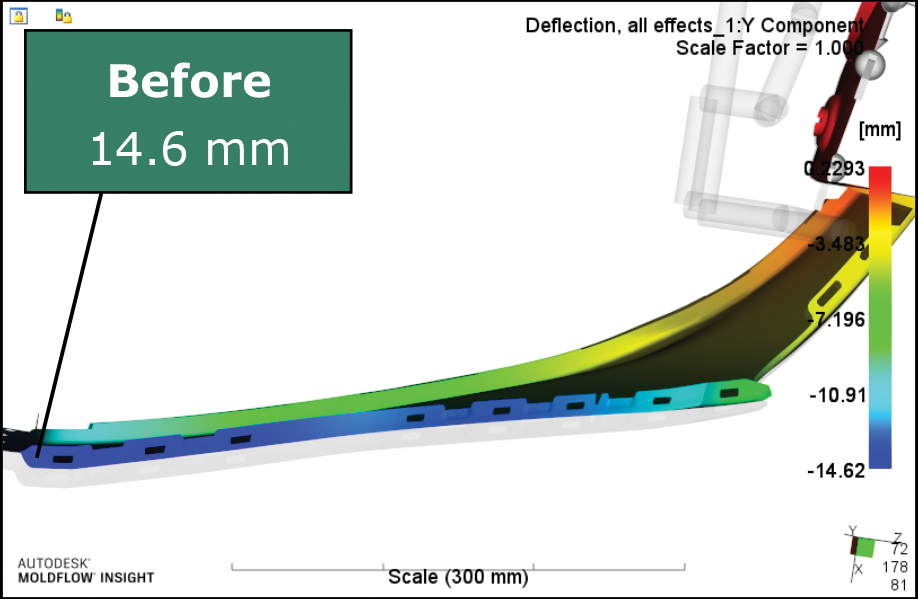

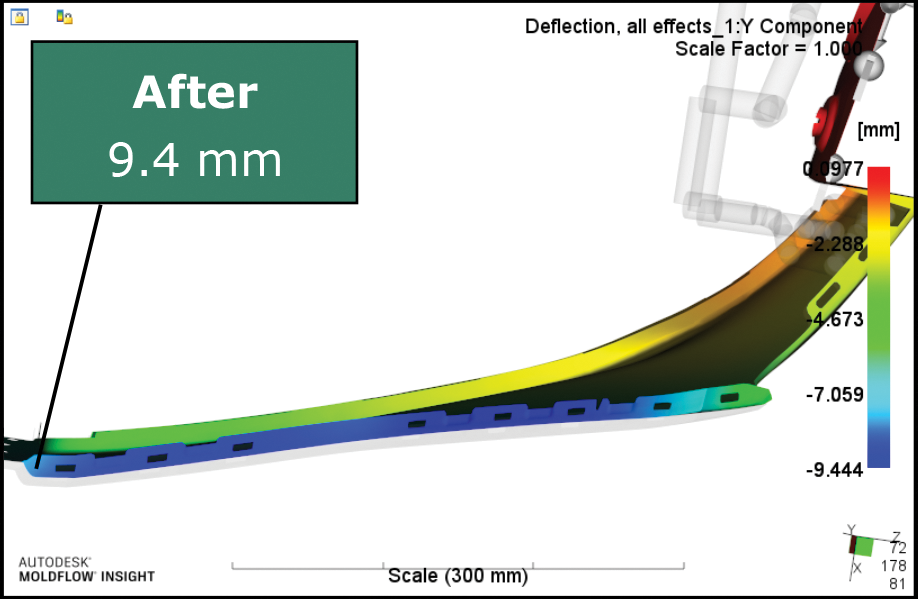

Predict - Identify - Solve (Conformal Cooling)

Conformal cooling led to warpage reduction.

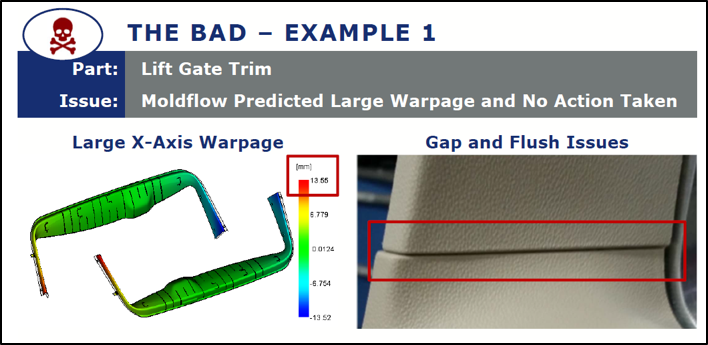

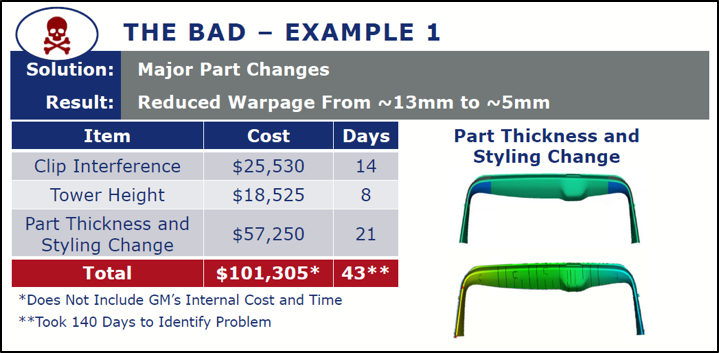

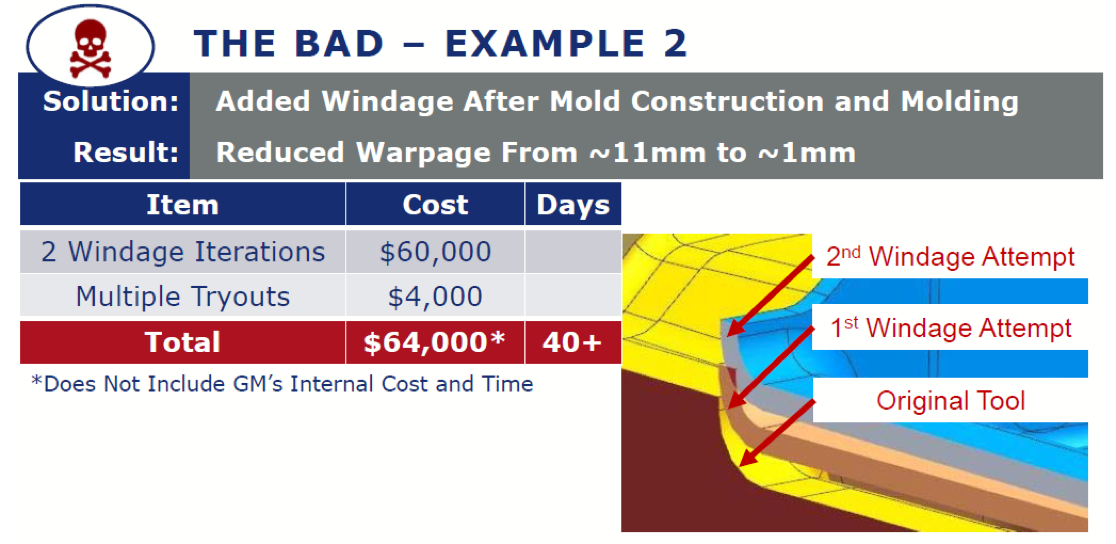

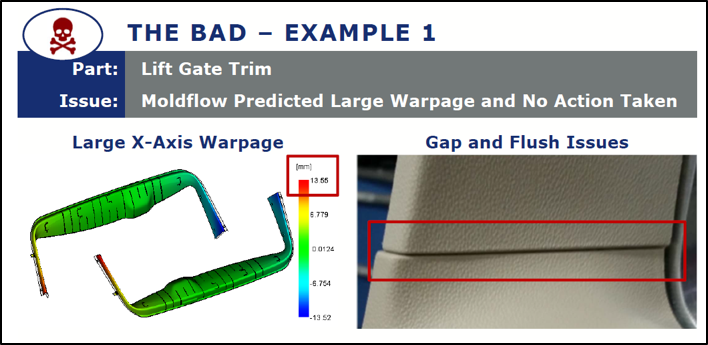

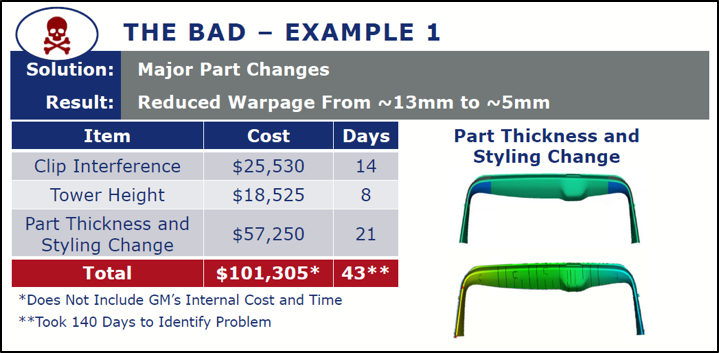

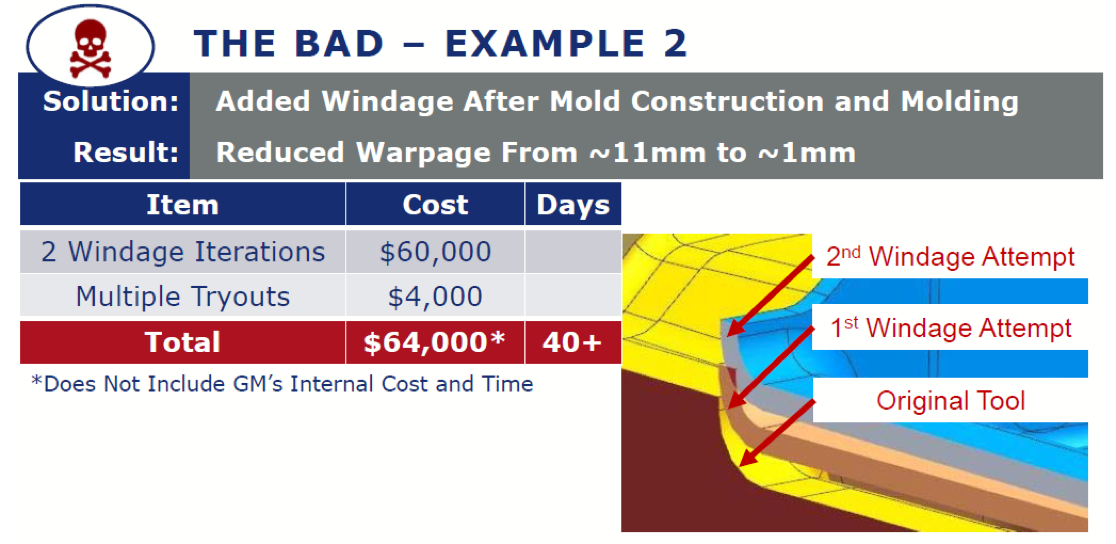

Consequences of Ignoring Standards

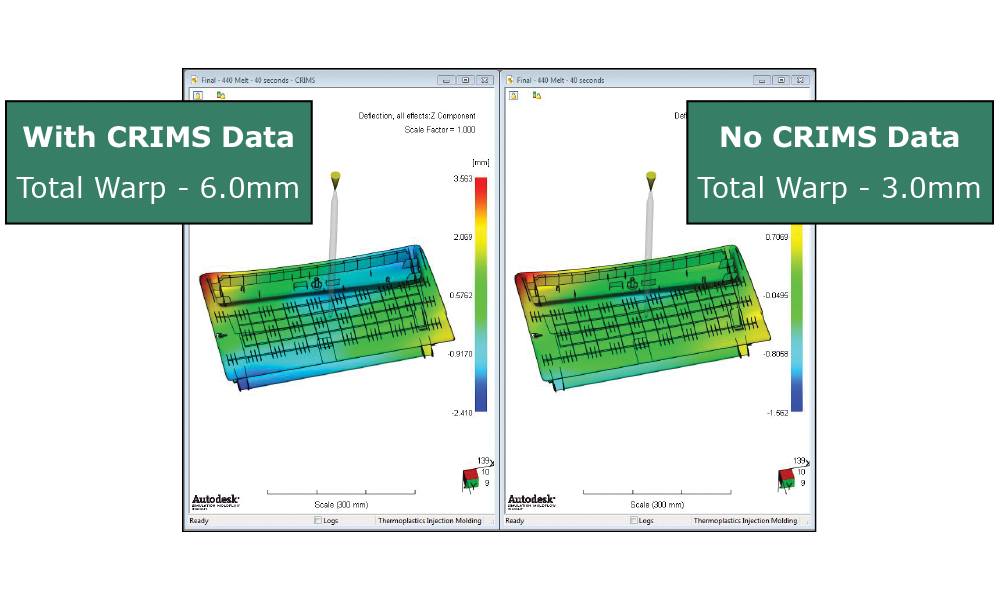

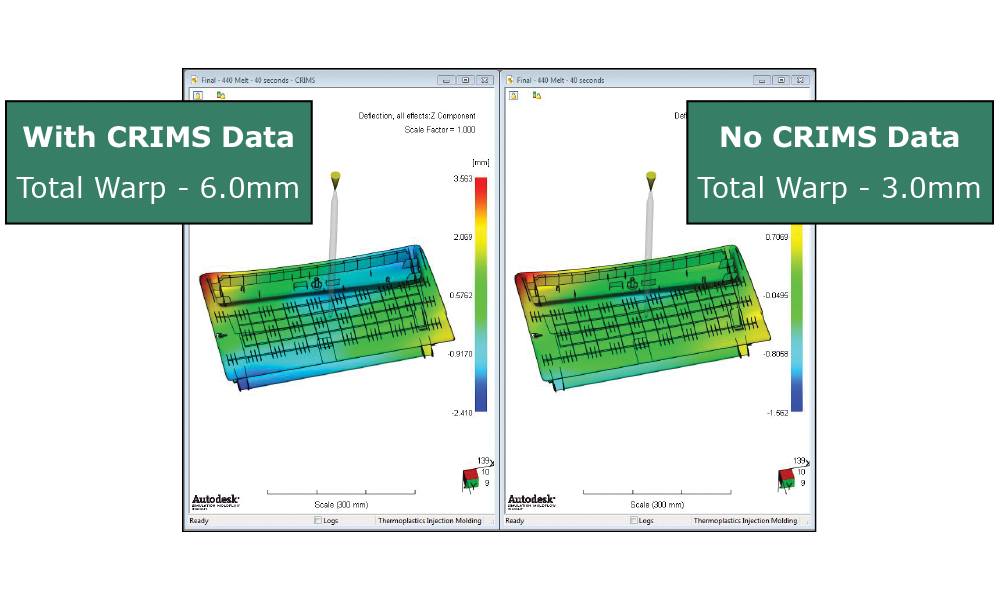

Incomplete Material Testing

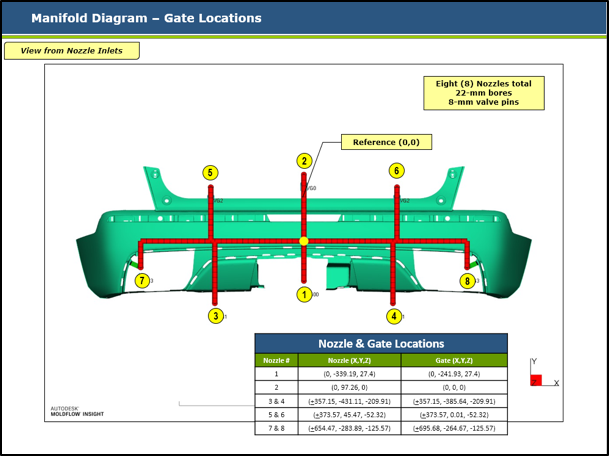

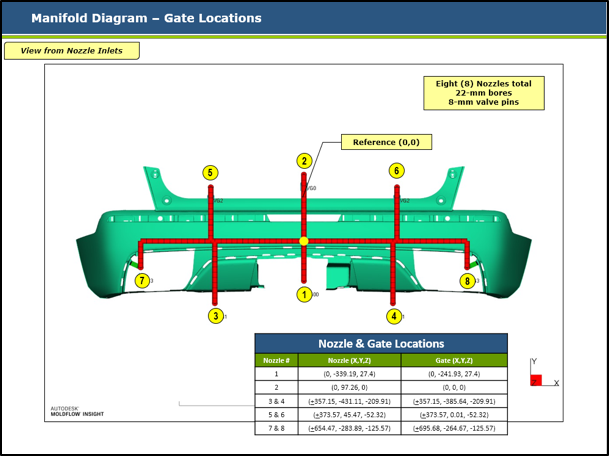

Preliminary Reports - Example

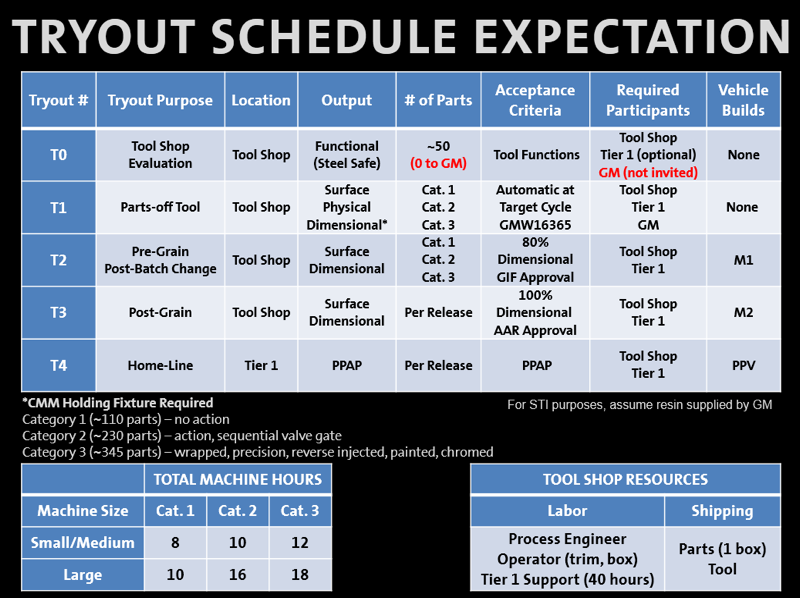

GMW 16365 - The T1 Tryout

Correlation process at T1 tryout

-

Goal – produce an acceptable part for GM10067 submission

-

GM buys good parts, not processes

-

-

Phase 4 – optimum Moldflow process

-

If parts not acceptable, part supplier optimizes process at T1 and forwards process to Moldflow source

-

-

Phase 4a - updates analysis with T1 process and part mold design changes

-

Phase 5 process is run

-

Correlation of final tryout process with Moldflow

-

Correlation Scorecard

-

Documents the T1 tryout

-

Dimensional & appearances responses

-

3 sets of measurements – forward and backward correlation

-

To be filled out during/after the T1 tryout

Some Advice

-

Rely on Experts

- CAE Services has attended dozens of T1 tryouts

- Become Expert-certified, or use our services

-

Be prepared

-

Have a pre-T1 meeting

-

-

Work collaboratively

- Lean on GM

- Working independently can sink a program

- Particularly important at the T1 tryout

-

Be honest when things aren’t working

- Sir Walter Scott – “Oh, what a tangled web we weave…”

- Bad news is way better early than late

- Have opportunity/time to fix problems

- Feedback to Autodesk makes things better for everyone

Understanding GM’s Moldflow Requirements

Ask The Moldflow Experts Webinar Topic:

Understanding GM’s Moldflow Requirements

August 17th, 2021 | 12:30 PM CDT

Becoming familiar with GM’s requirements for Moldflow analysis can be a daunting task. Join us as we help you navigate through General Motors’ Appendix E8 manufacturing standards for thermoplastic injection molded parts. As members of GM’s Moldflow Advisory Board, CAE Services is intimately familiar with the process. We have also lived it, having worked on hundreds of GM molds and attended numerous T1 tryouts (too many to count!). Specifically, here is what will be covered:

GMW16355 – Thermoplastic Injection Molding Analysis

Why these standards are necessary

Personnel required

5 Phases of Moldflow

Reporting requirements

GMW16365 – Thermoplastic Injection Mold T1 Tryout Protocol

Personnel required

At the press – detailed procedures

Filling out the Moldflow Scorecard

How to make it work!

ATME – Take Away

If you are experiencing cycle time or warpage related problems:

Email Us Today!

#id-4011 .carousel-slider-nav-icon {

fill: #f1f1f1

}

#id-4011 .carousel-slider-nav-icon:hover {

fill: #00d1b2

}

#id-4011 .owl-prev,

#id-4011 .owl-next,

#id-4011 .carousel-slider-nav-icon {

height: 48px;

width: 48px

}

#id-4011.arrows-outside .owl-prev {

left: -48px

}

#id-4011.arrows-outside .owl-next {

right: -48px

}

#id-4011 .owl-dots .owl-dot span {

background-color: #f1f1f1;

width: 10px;

height: 10px;

}

#id-4011 .owl-dots .owl-dot.active span,

#id-4011 .owl-dots .owl-dot:hover span {

background-color: #00d1b2

}

Benefits of GM Moldflow Standards

Predict – Identify – Solve (Conformal Cooling)

Conformal cooling led to warpage reduction.

Consequences of Ignoring Standards

Incomplete Material Testing

Preliminary Reports – Example

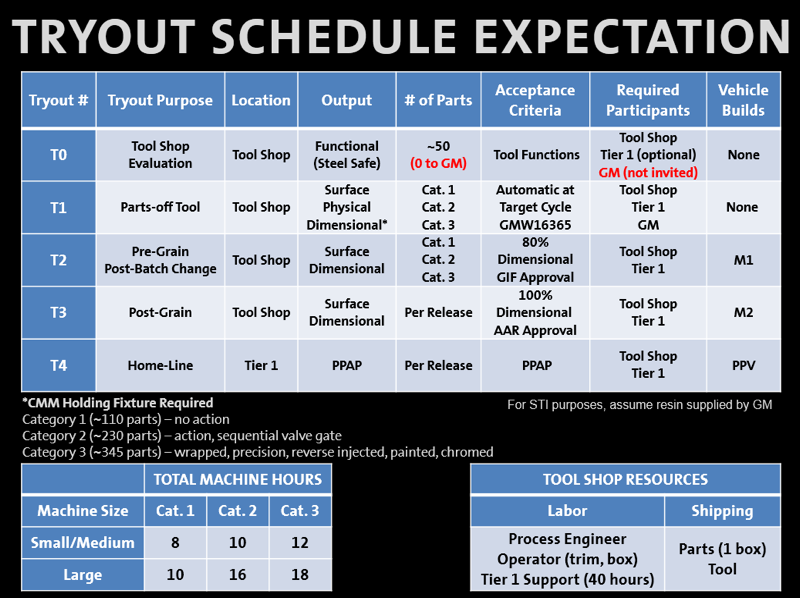

GMW 16365 – The T1 Tryout

Correlation process at T1 tryout

Goal – produce an acceptable part for GM10067 submission

GM buys good parts, not processes

Phase 4 – optimum Moldflow process

If parts not acceptable, part supplier optimizes process at T1 and forwards process to Moldflow source

Phase 4a – updates analysis with T1 process and part mold design changes

Phase 5 process is run

Correlation of final tryout process with Moldflow

Correlation Scorecard

Documents the T1 tryout

Dimensional & appearances responses

3 sets of measurements – forward and backward correlation

To be filled out during/after the T1 tryout

Some Advice

Rely on Experts

CAE Services has attended dozens of T1 tryouts

Become Expert-certified, or use our services

Be prepared

Have a pre-T1 meeting

Work collaboratively

Lean on GM

Working independently can sink a program

Particularly important at the T1 tryout

Be honest when things aren’t working

Sir Walter Scott – “Oh, what a tangled web we weave…”

Bad news is way better early than late

Have opportunity/time to fix problems

Feedback to Autodesk makes things better for everyone