Ask The Moldflow Experts

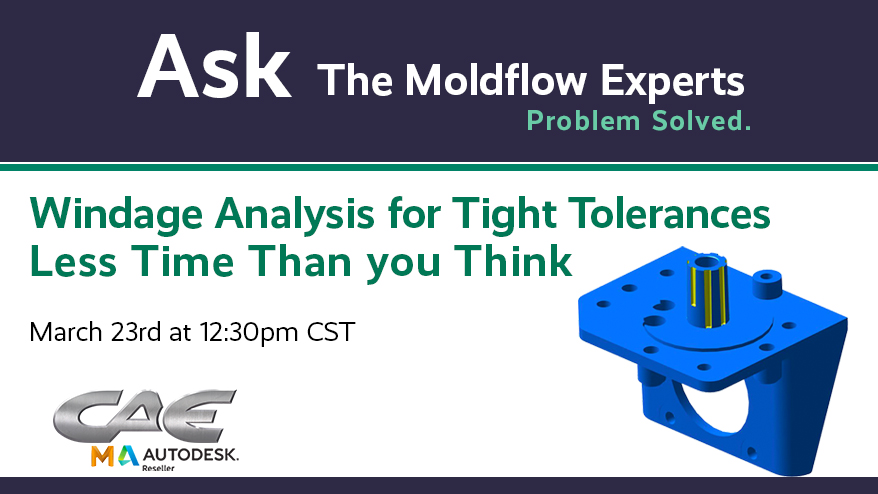

Windage Analysis for Tight Tolerances... Less Time Than You Think

Ask The Moldflow Experts Webinar Topic:

Windage Analysis for Tight Tolerances... Less Time Than You Think

March 23rd, 2021 | 12:30 PM CDT

Learn how Moldflow identified & solved a tight tolerance application in days, not weeks.

During the health care challenges of the past year, CAE Services Corporation was called upon to work on several parts for the Ventec Life Systems ventilator. With 700 parts required to make one ventilator, many of which are injection molded, the task to ramp up tooling and production was monumental. The part we analyzed was a critical component for the oxygen-metering valve assembly.

This webinar discussed

- How Moldflow is used in solving tight warpage tolerances using Windage & CAD Morphing

- Factors used in determining when to use Windage

- Determining Shrinkage number for best results

- Correlation of final molded samples with Windage analysis

ATME - Take Away

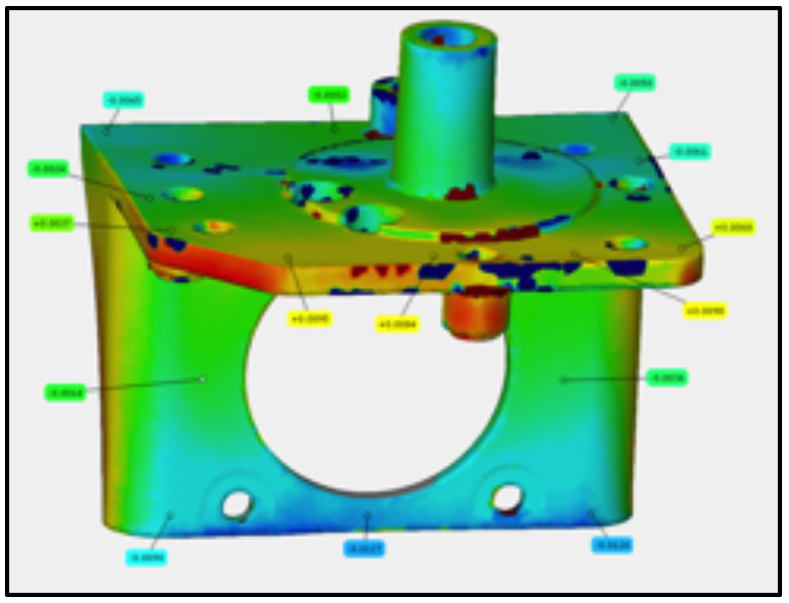

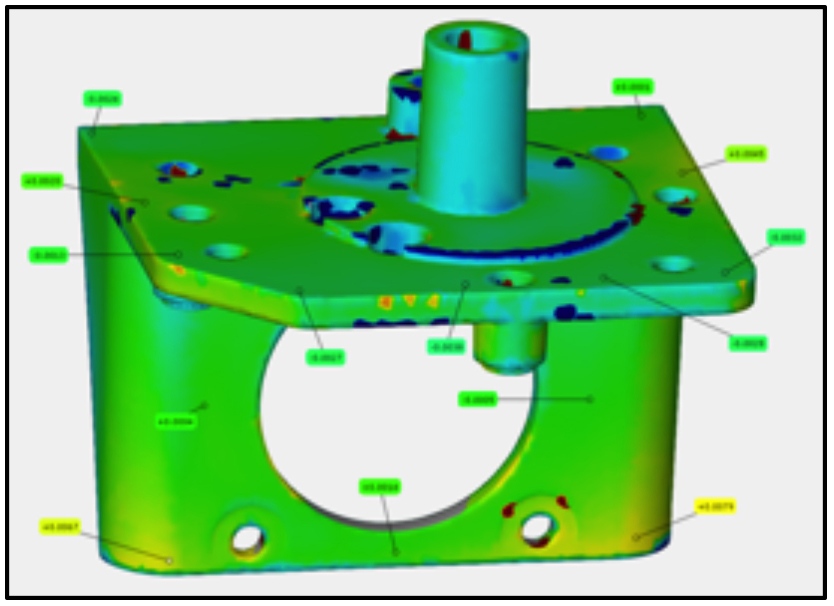

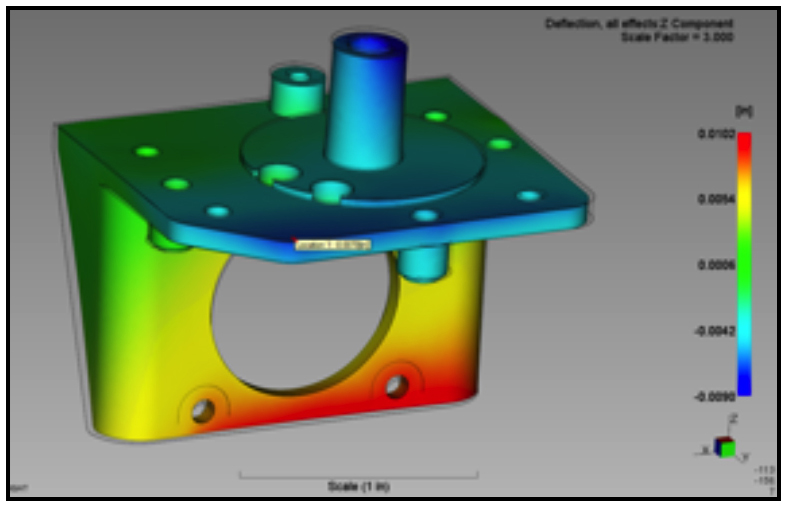

Step 1 - Correlation Existing Warpage

- Old material deck predicted right trend, wrong magnitude

- New material deck predicted trend and magnitude correctly

- Determined cause of warpage to be fiber orientation

Old Material Deck

Max deviation = 0.014”

New Material Deck

Max deviation = 0.008”

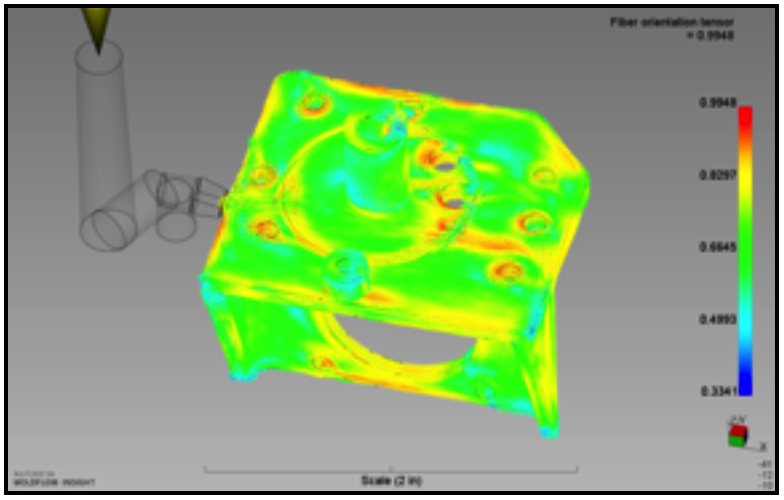

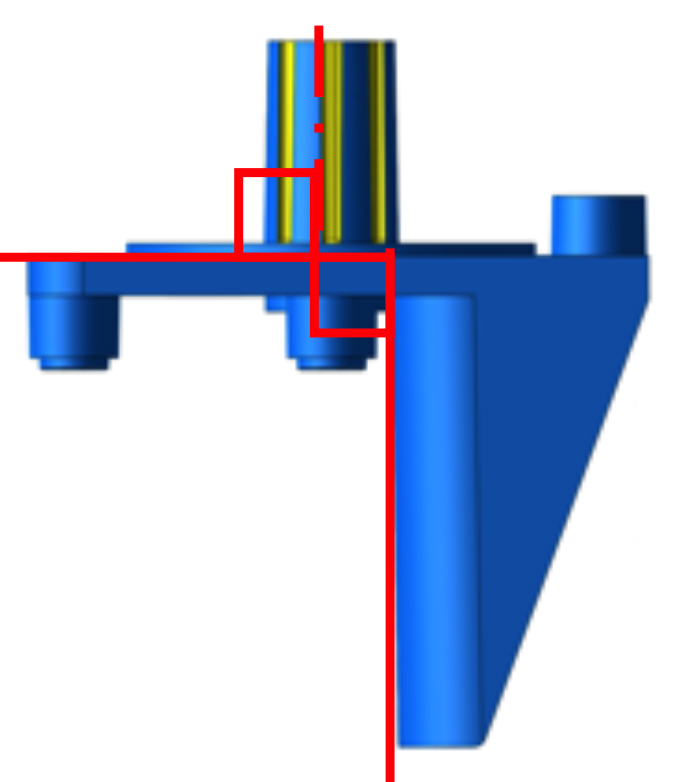

Step 2 – Minimize Warpage

- Change Gate Location for more favorable fiber alignment

- Warpage reduced slightly, but not within tolerance

- Sink marks eliminated

Max. Deflections

Downward - 0.0070”

Inward – 0.0099”

Fiber Orientation More Uniform Across Part

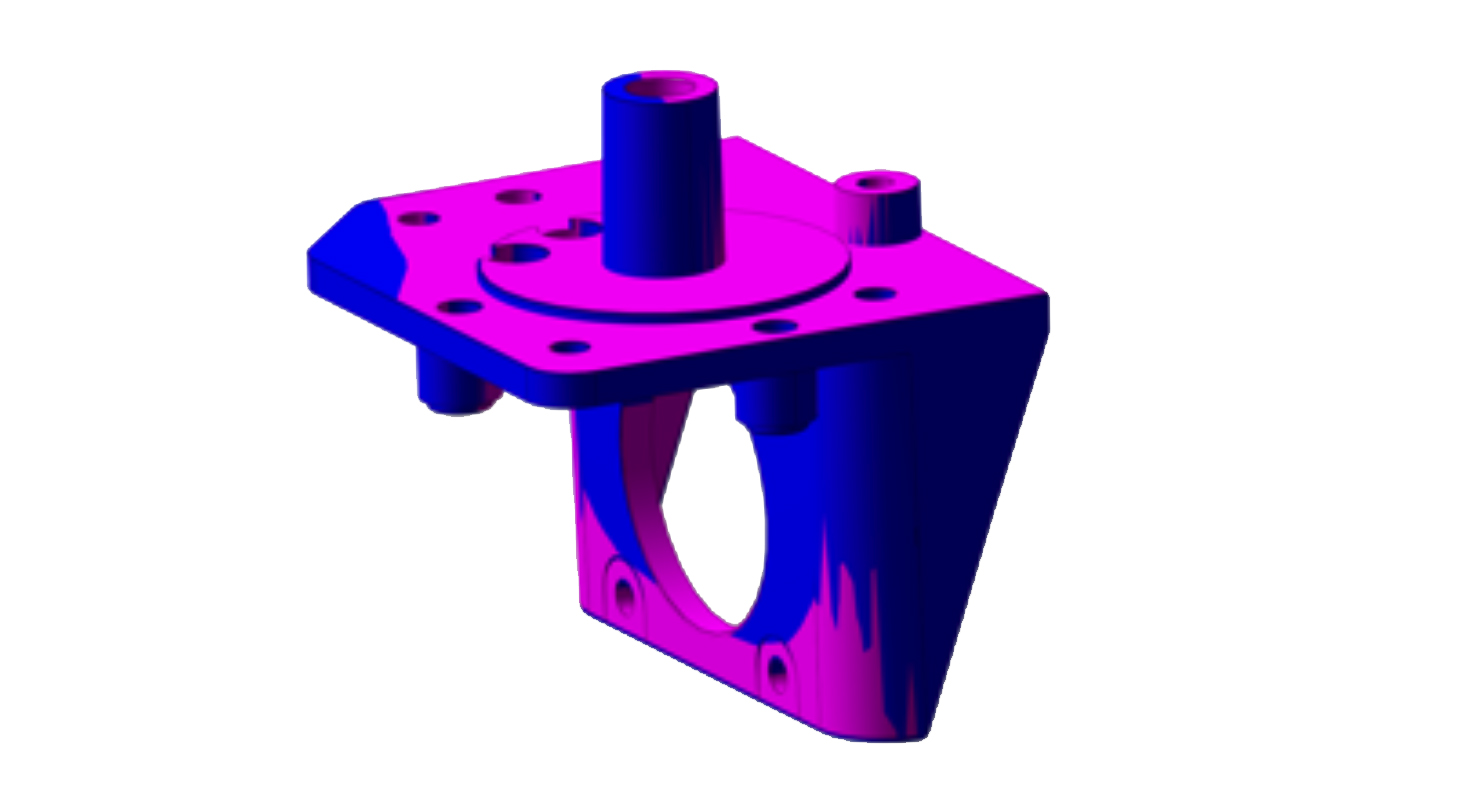

Step 3 – Use Windage to Fix Warpage

- Determine Windage Factor

- Decide on Shrinkage Number

- Morph the Part (avoid die lock)

- Confirm in Moldflow

- One week to complete analysis, material testing, and delivery of morphed windage file.

Purple = Nominal

Blue = Windage

Step 4 - Final Molded Samples - Dimensions

- Perpendicularity of L-shape

- Actual = (0.005, 0.004, 0.005)

- Well within 0.010” tolerance

- Perpendicularity of boss (0.0025”)

- Actual = (0.0011, 0.0013, 0.0012)

- Well within 0.0025” tolerance

Windage Analysis for Tight Tolerances… Less Time Than You Think

Windage Analysis for Tight Tolerances… Less Time Than You Think

March 23rd, 2021 | 12:30 PM CDT

ATME – Take Away

Step 1 – Correlation Existing Warpage