Ask The Moldflow Experts

How To Identify & Solve Warpage Problems

Ask The Moldflow Experts Webinar Topic:

How To Identify & Solve Warpage Problems

October 19th, 2021 | 12:30 PM CDT

Anyone that is involved in the design or manufacturing of injections molded plastic parts has faced warpage problems at one time or another. Join this webinar to see how CAE Services’ Experts solve warpage problems and plan to avoid them in the first place.

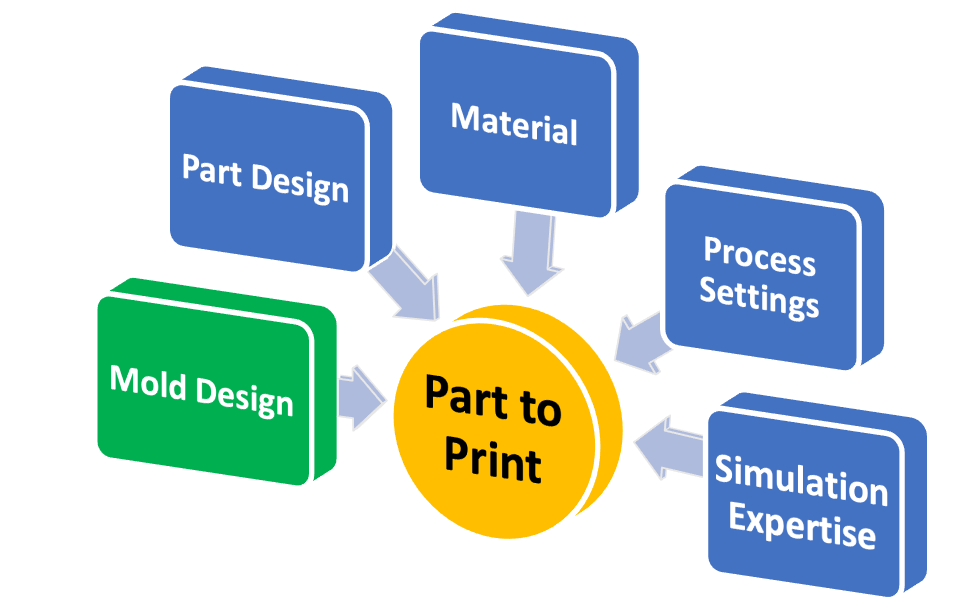

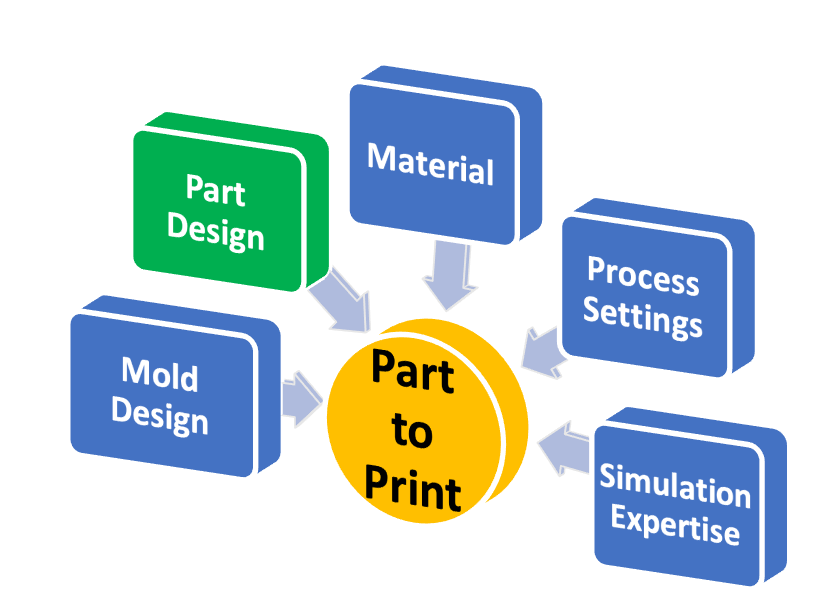

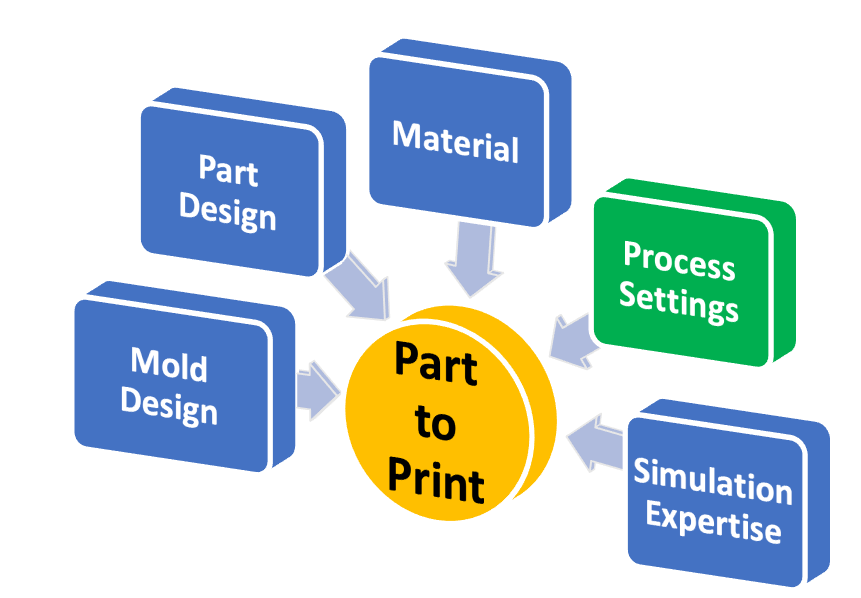

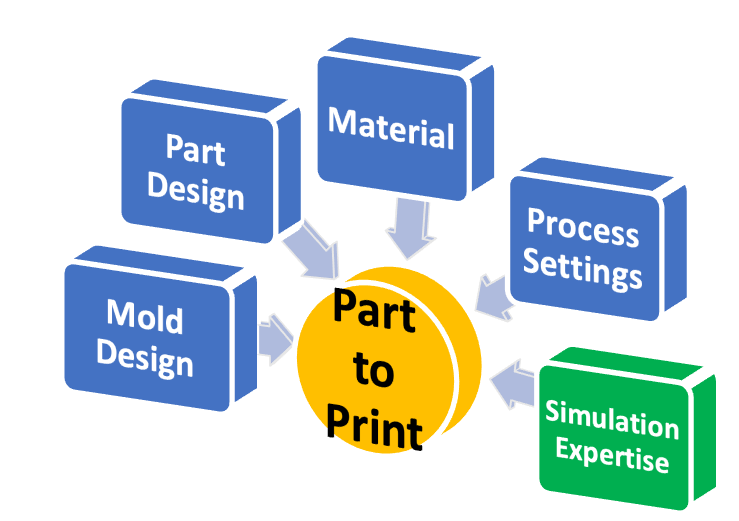

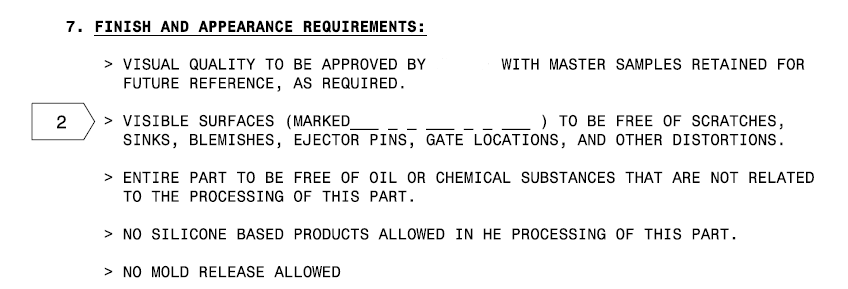

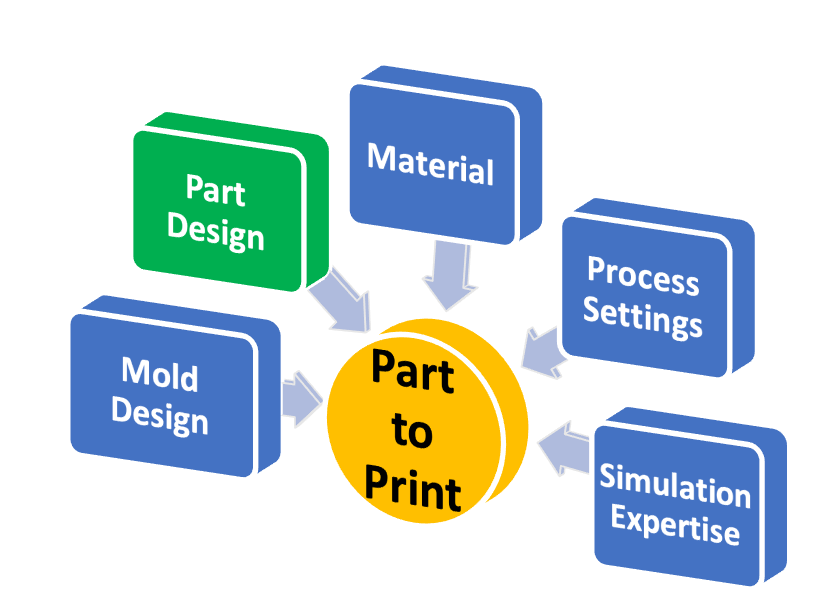

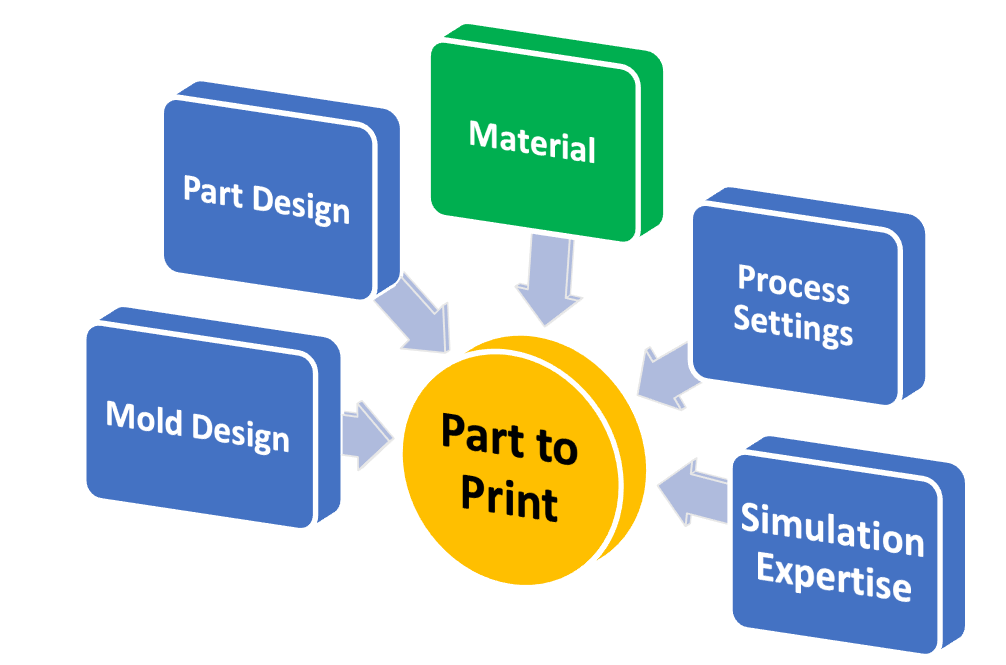

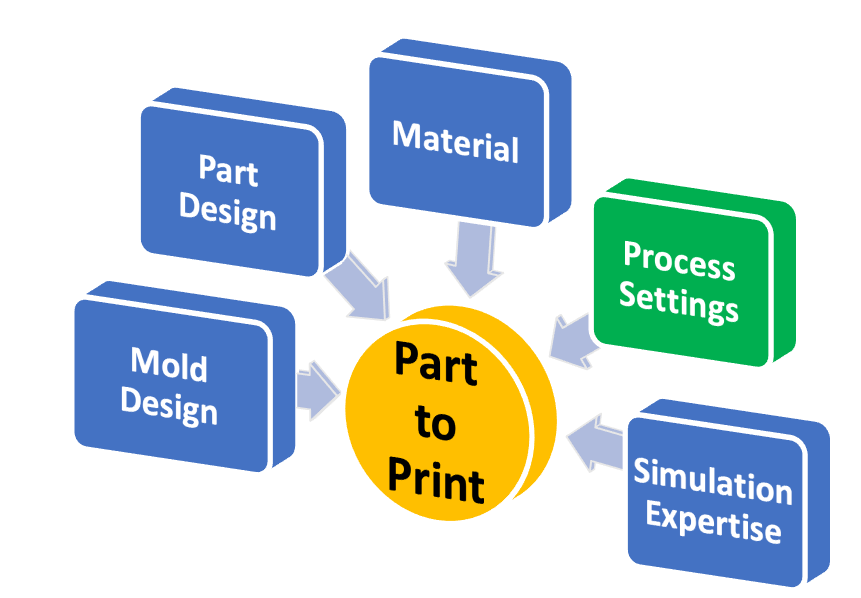

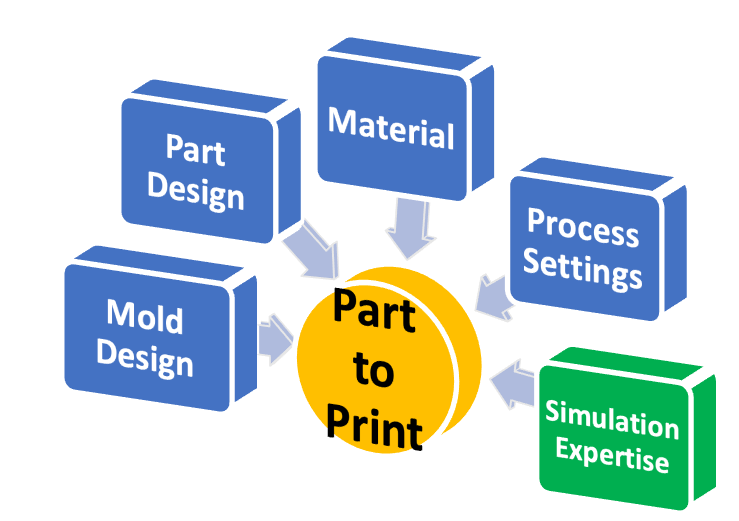

- Learn how decisions about mold design, part design, materials, and process settings affect the final dimensions of your part

- Learn strategies for using Moldflow simulation to get your plastic part dimensions to print even before production startup.

- Discover how Part-to-Print improves costs and timelines for plastic part production

- In-depth topic discussion with questions fielded during the presentation + Q&A at the end of the webinar

ATME - Take Away

Predict - Identify Solve

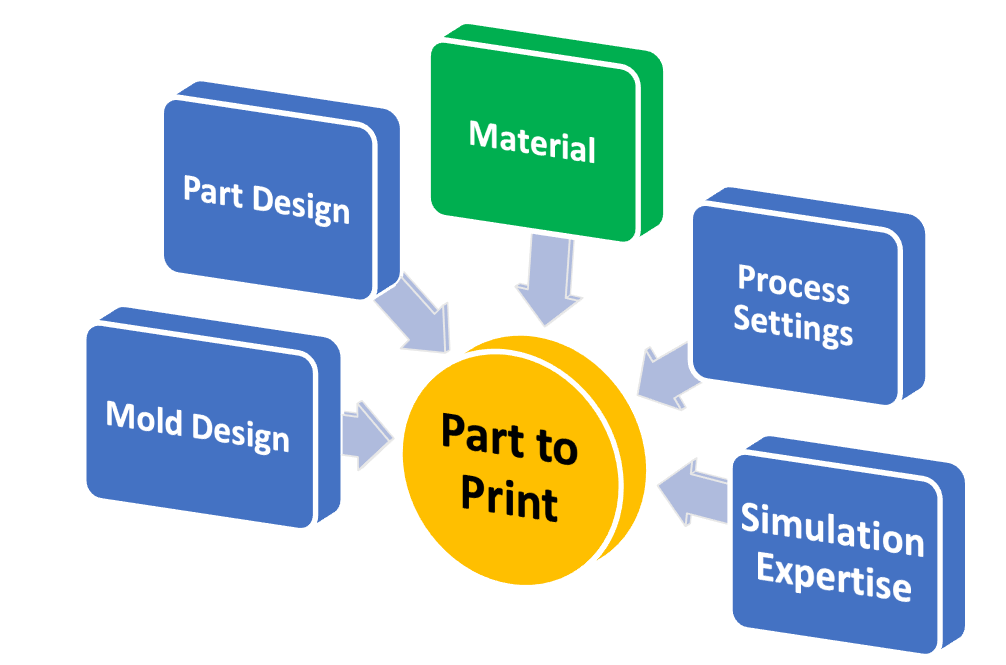

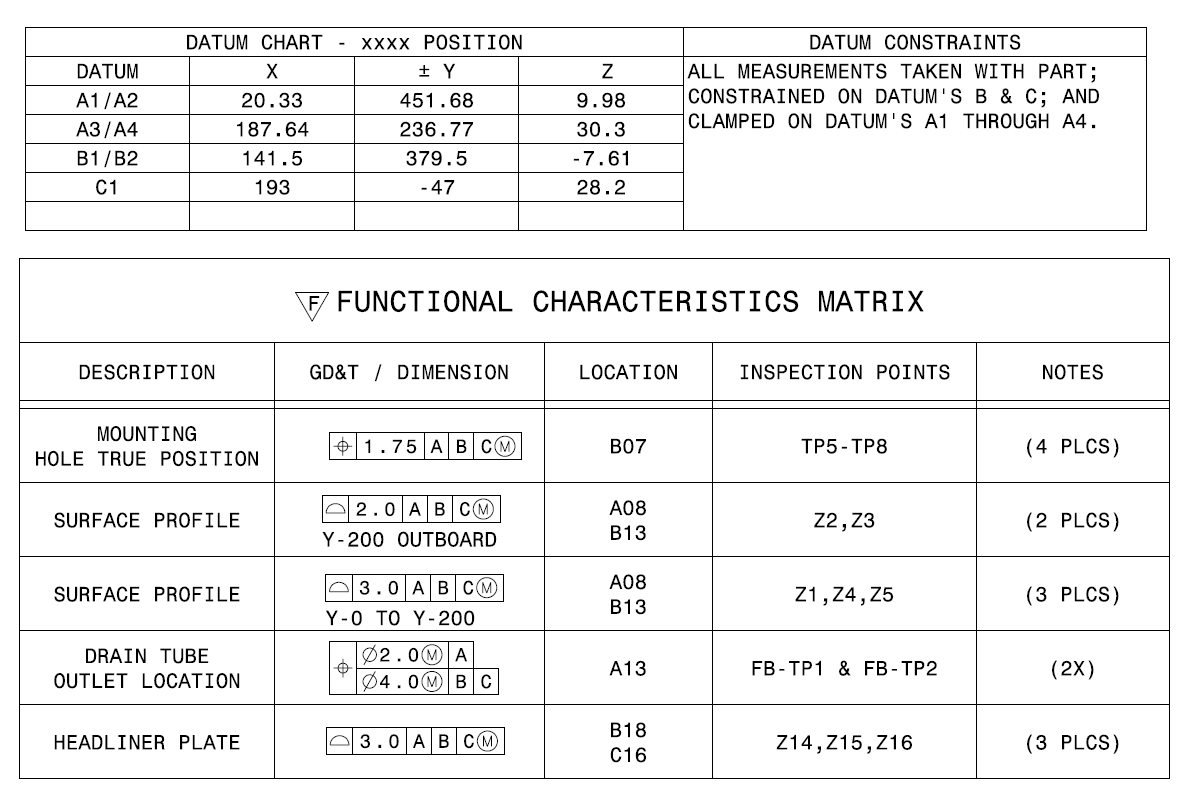

What is Part to Print?

-

Designer creates part design

-

Defines tolerances

-

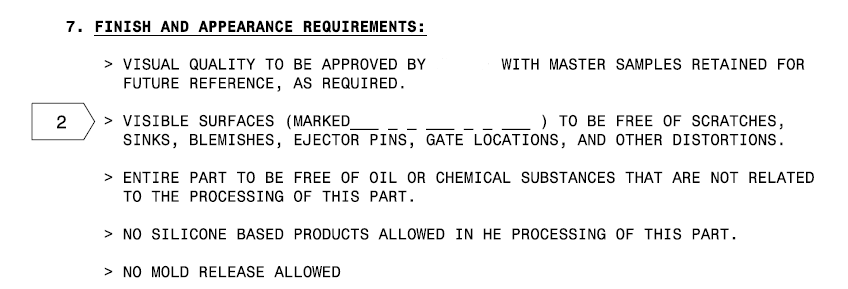

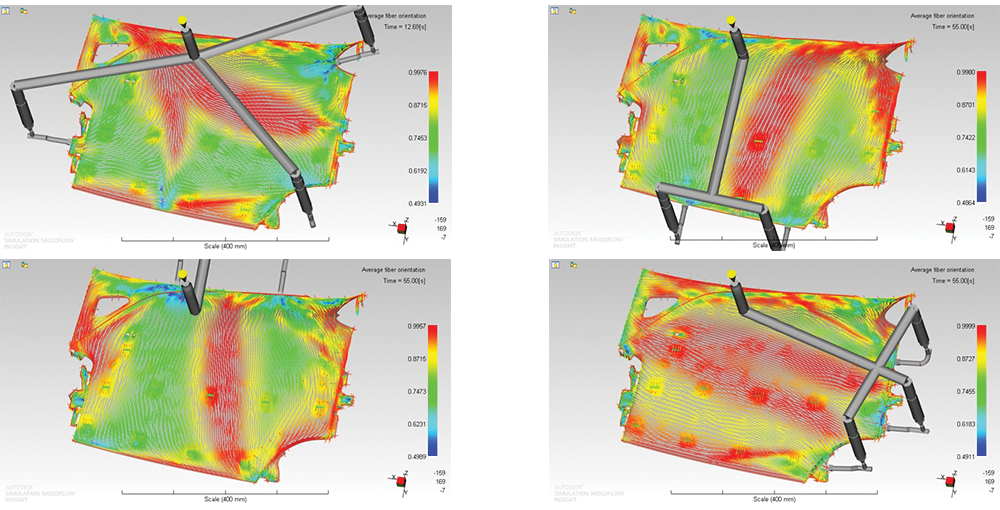

Defines aesthetics

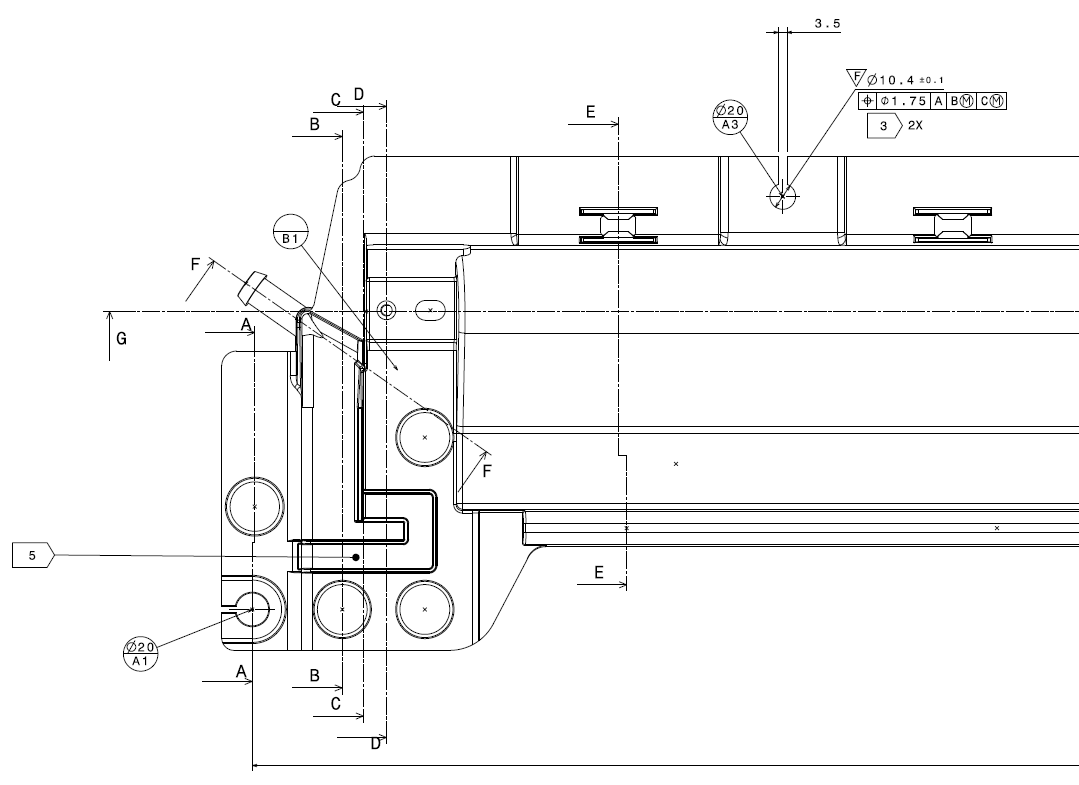

Focus on Mold Design

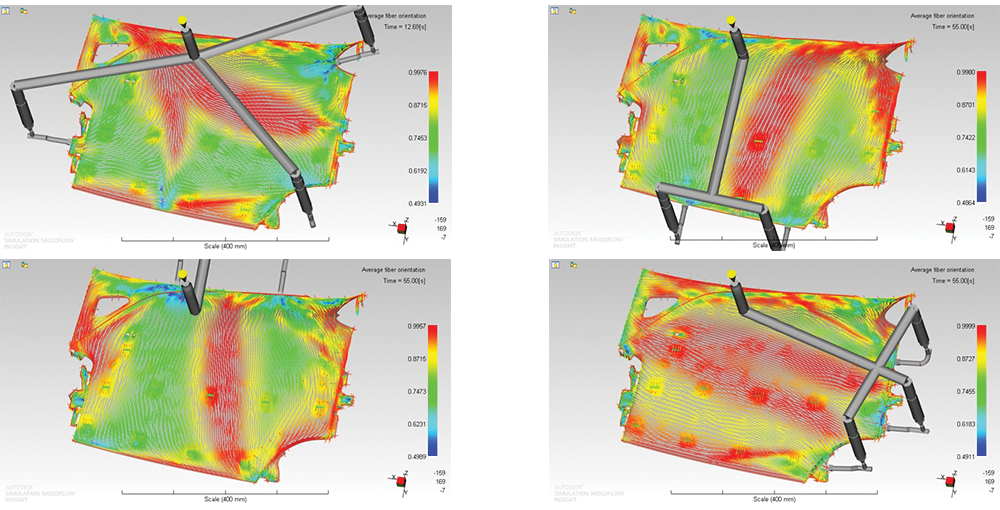

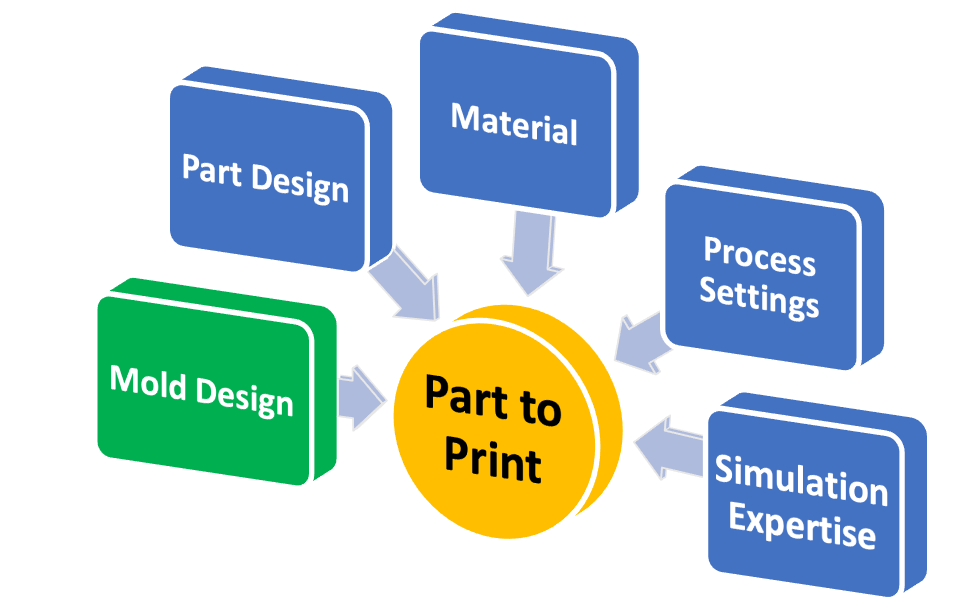

Gate Locations Affect Fiber Orientation

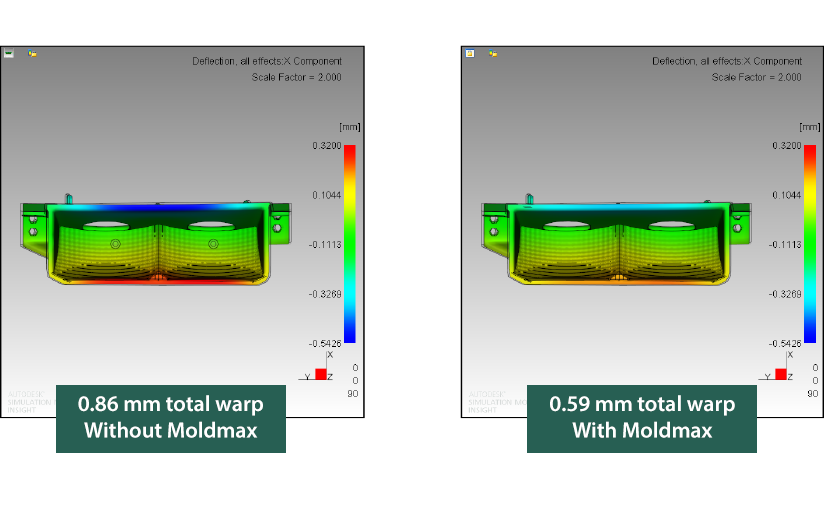

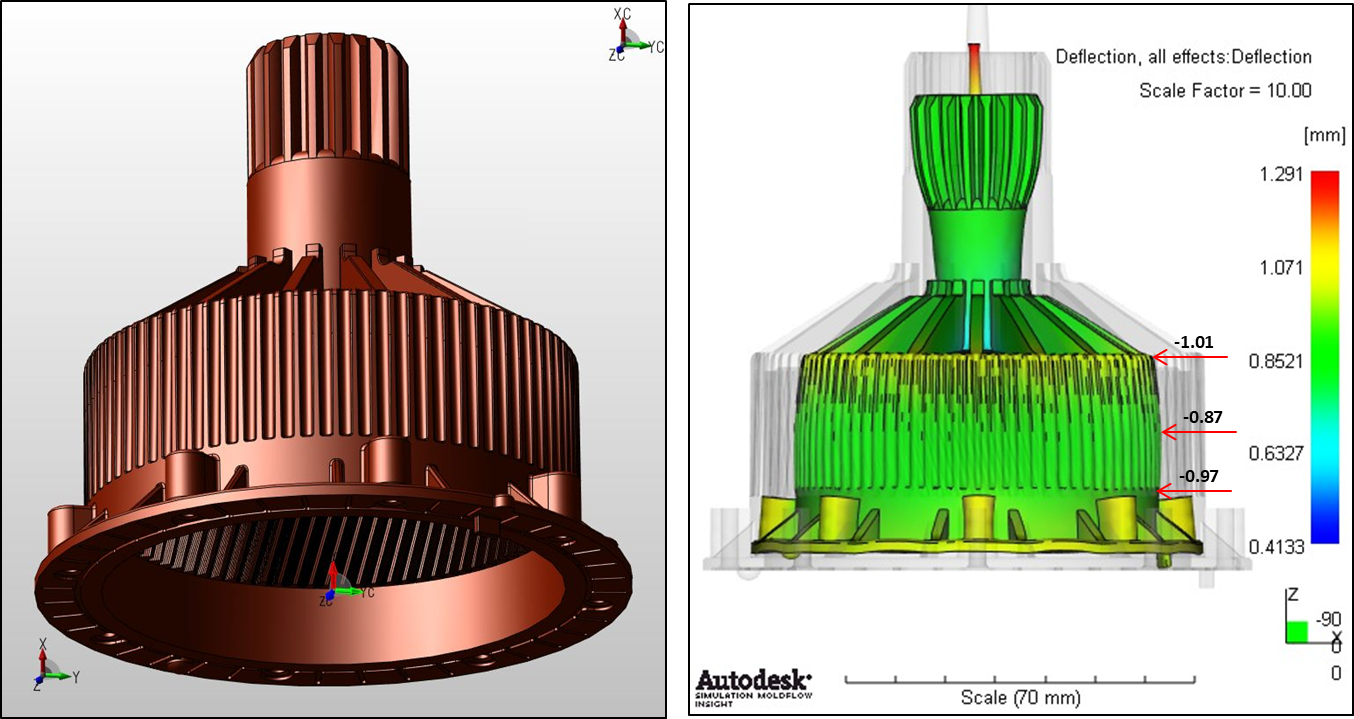

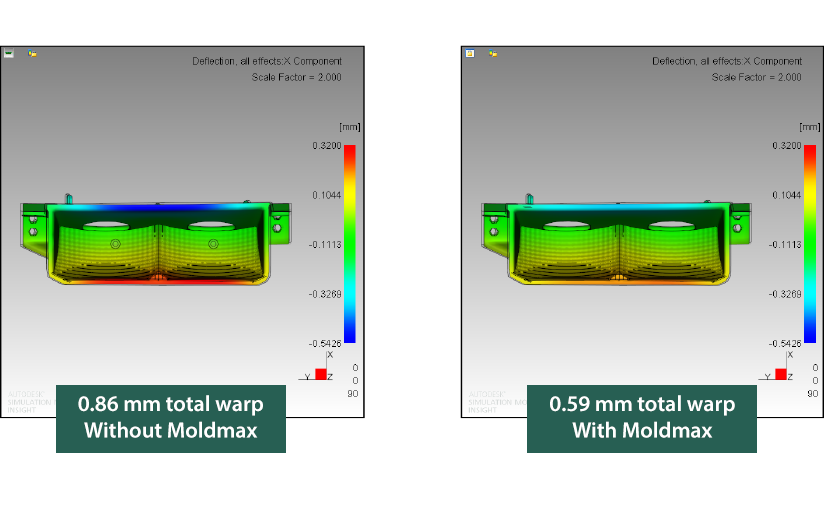

Moldmax Improved Part-to-Print

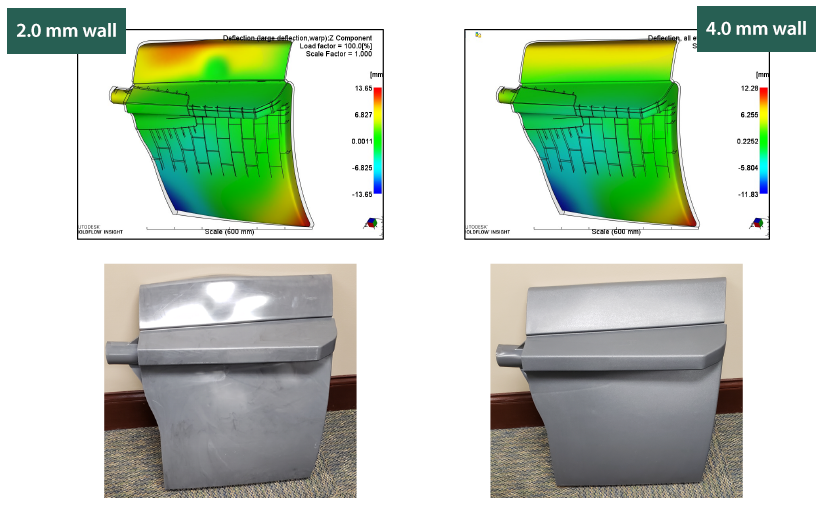

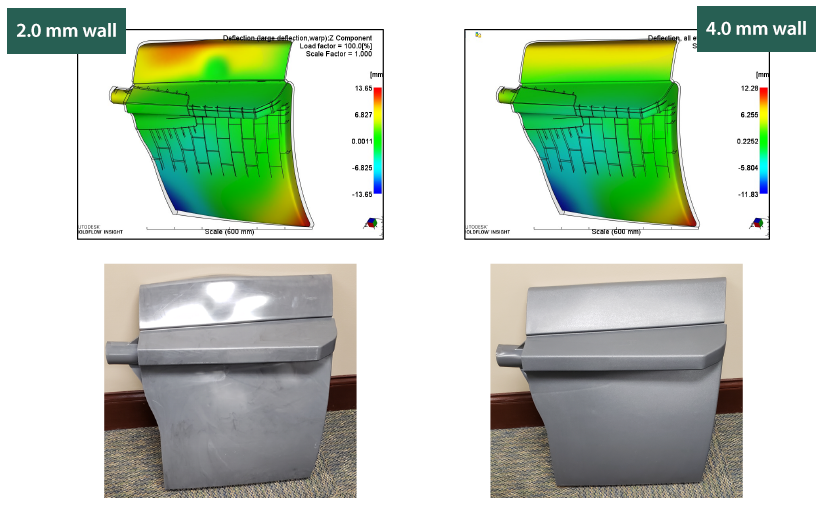

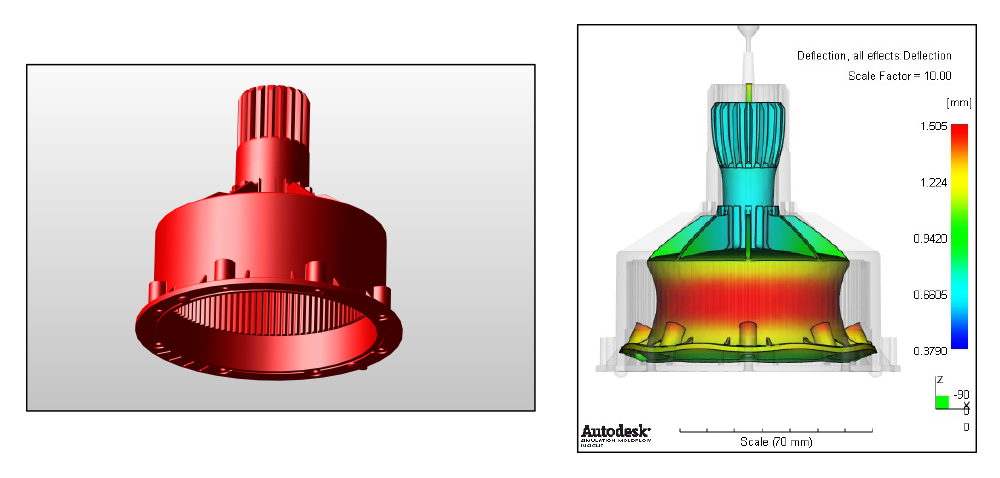

Focus on Part Design

Original Part Design

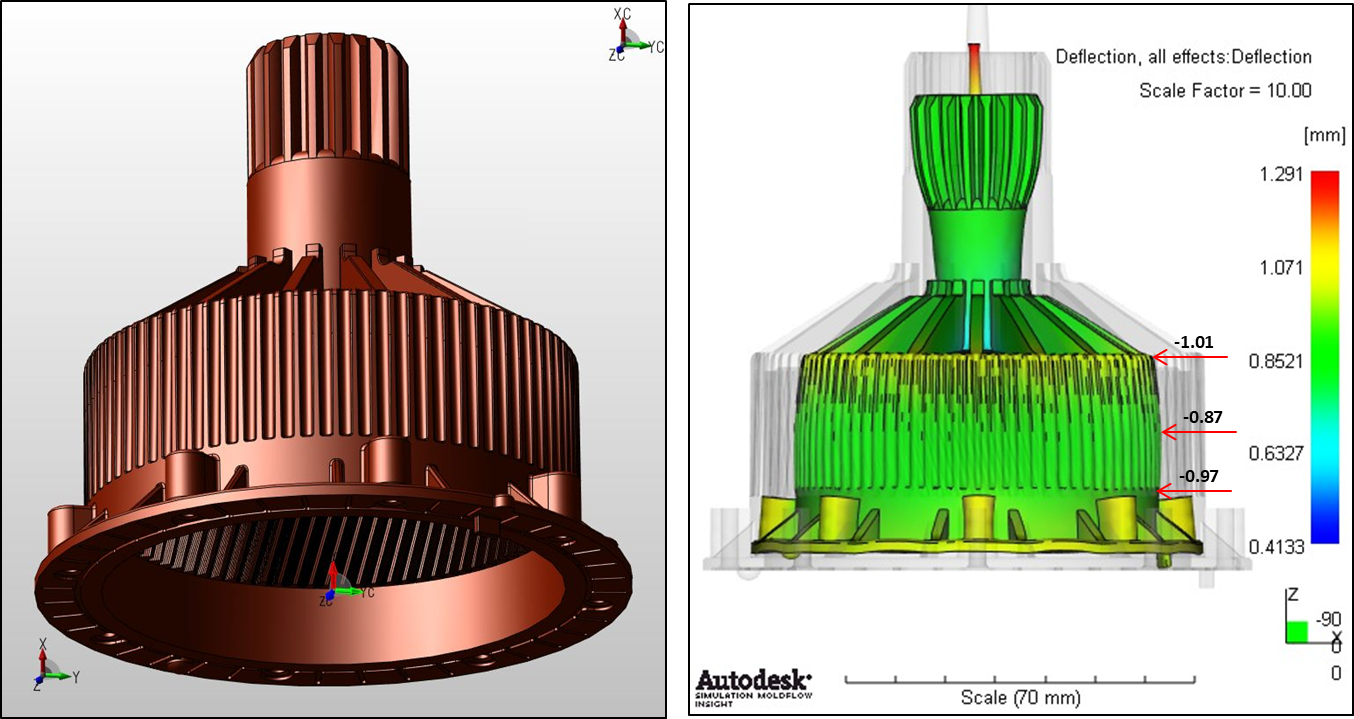

Revised Part Design #4

Focus on Material Properties

Substitute Materials Can Give Horrible Results

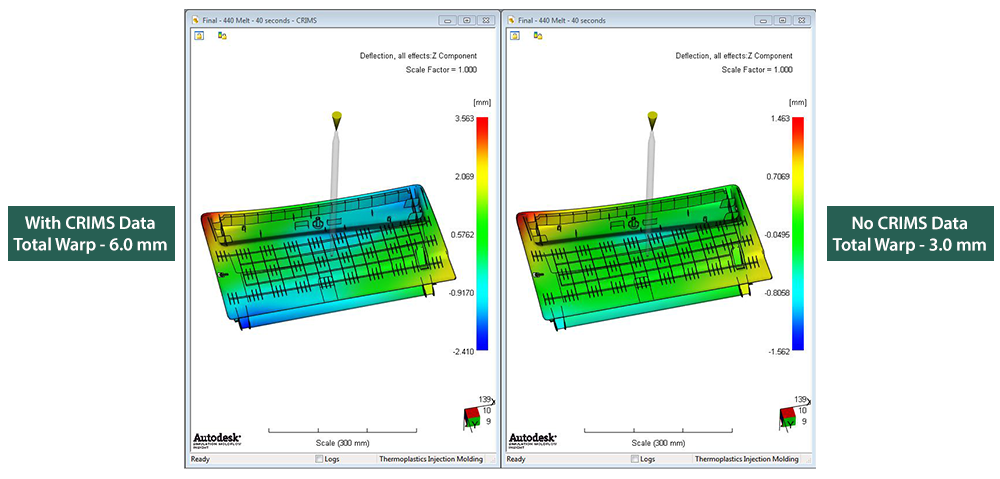

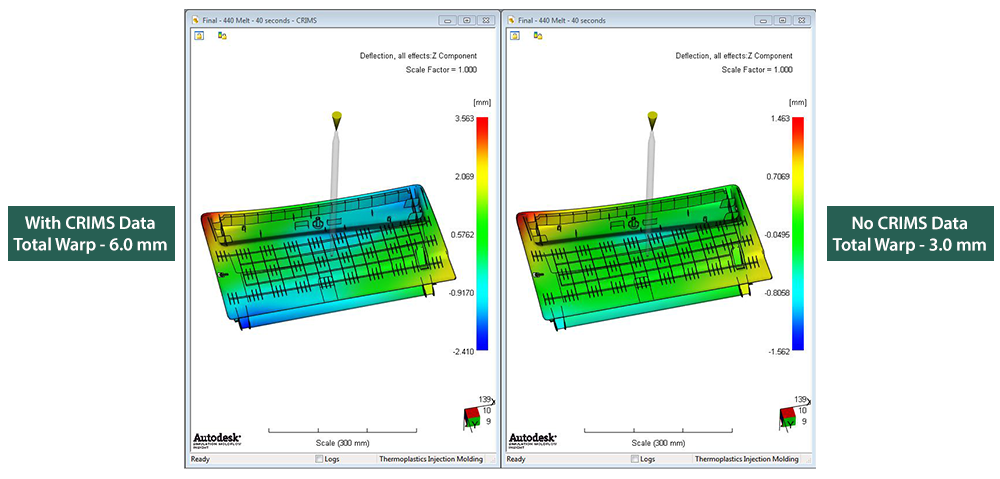

CRIMS Data Affects Warpage Predictions

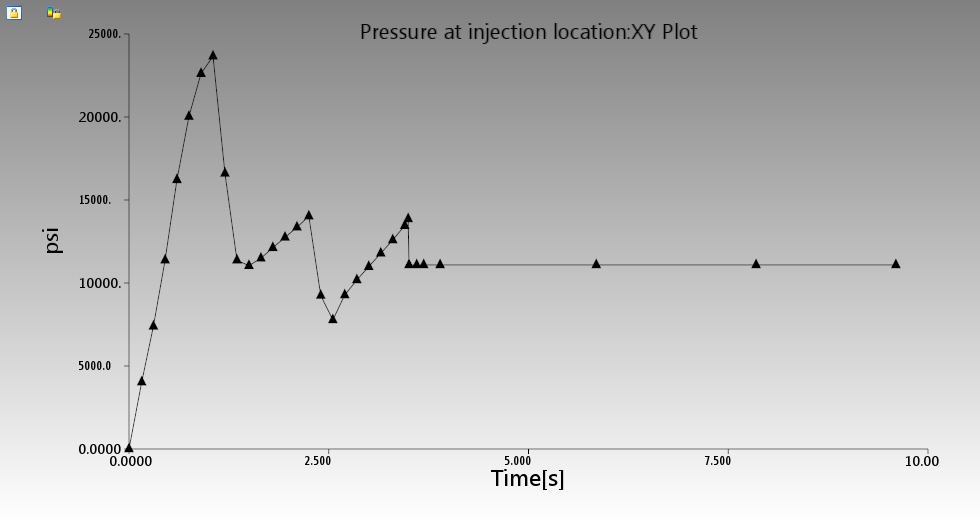

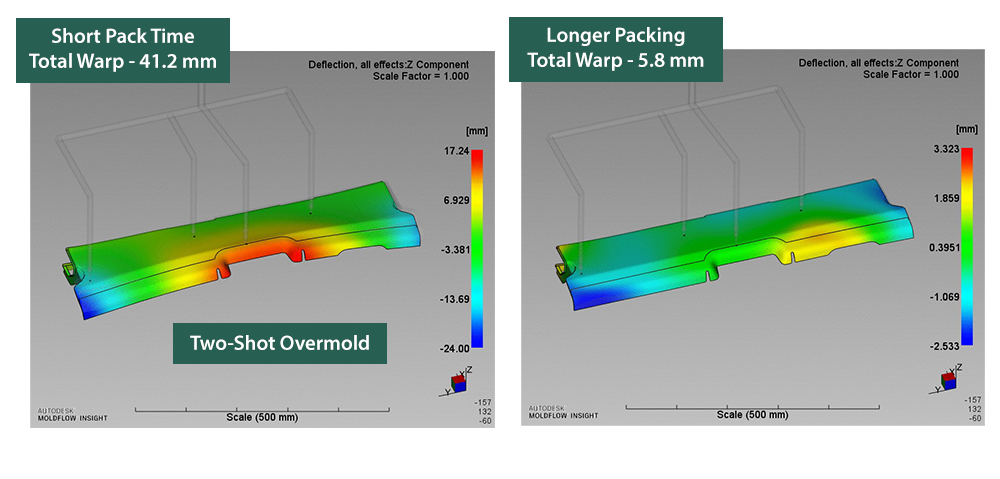

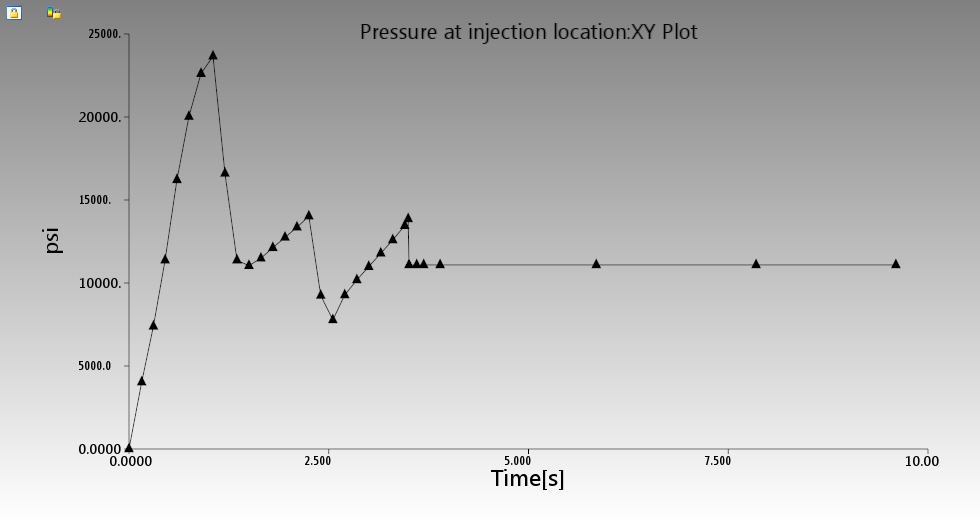

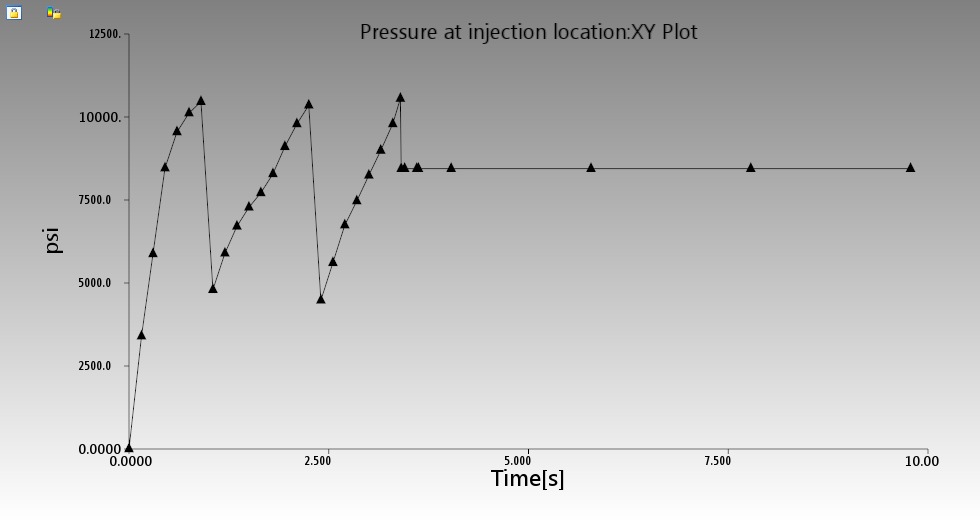

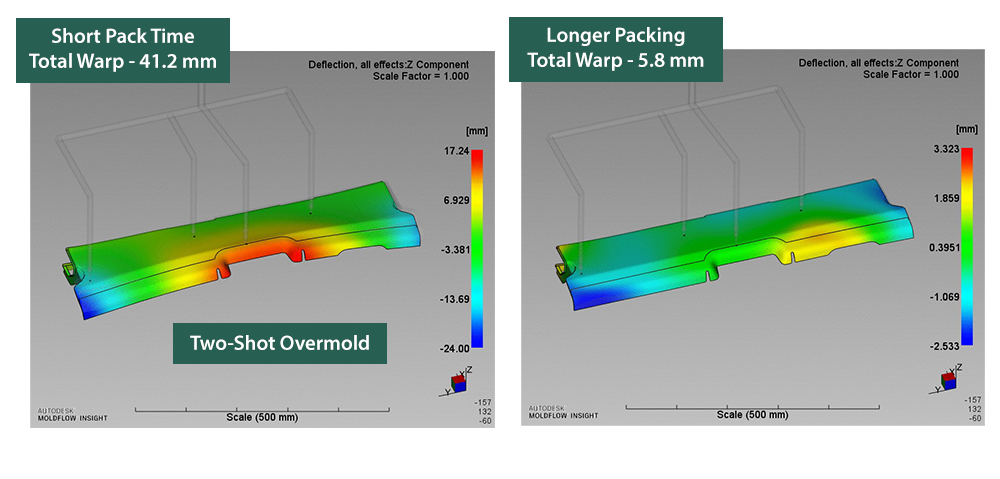

Focus on Process Settings

Medical Part - Fill Speed Impacts Aesthetics

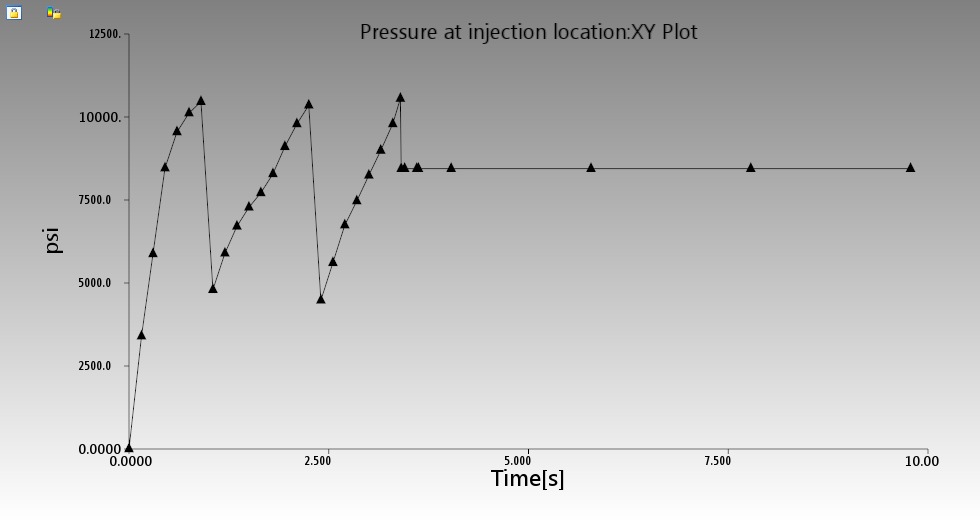

Pack Pressure/Time Impacts Part-to-Print

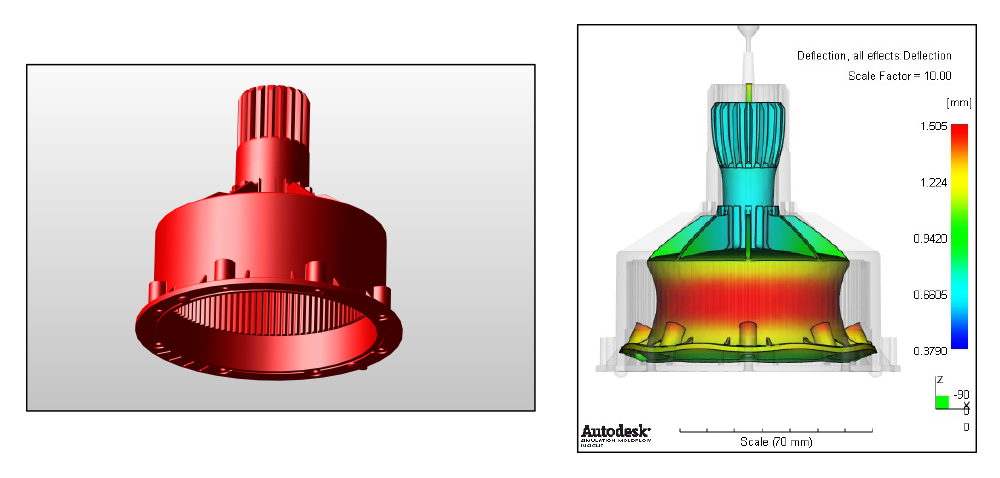

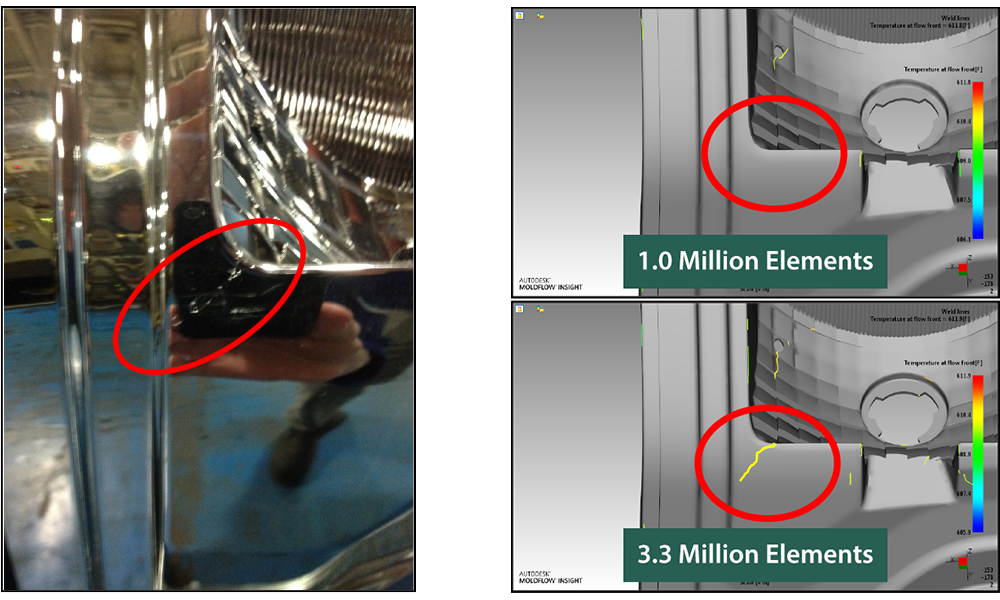

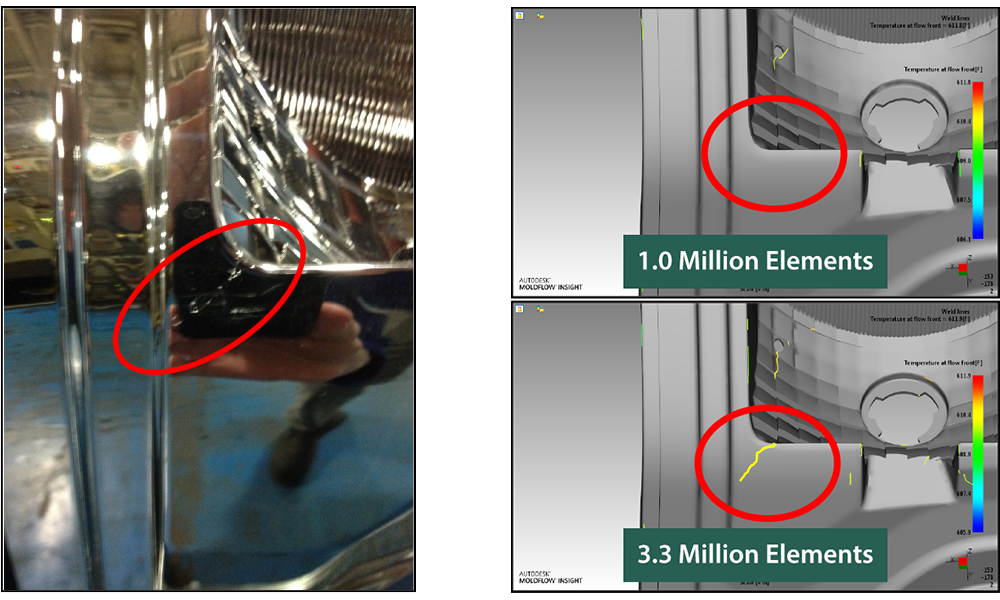

Focus on Simulation Expertise

Example - Fixing Mesh

Summary

Leveraging Moldflow helps:

-

Achieve Part-to-Print

-

Use data to inform decisions

-

Identify the best way to achieve goals

-

Manage the timeline

- Manage the budget

How To Identify & Solve Warpage Problems

Ask The Moldflow Experts Webinar Topic:

How To Identify & Solve Warpage Problems

October 19th, 2021 | 12:30 PM CDT

Anyone that is involved in the design or manufacturing of injections molded plastic parts has faced warpage problems at one time or another. Join this webinar to see how CAE Services’ Experts solve warpage problems and plan to avoid them in the first place.

Learn how decisions about mold design, part design, materials, and process settings affect the final dimensions of your part

Learn strategies for using Moldflow simulation to get your plastic part dimensions to print even before production startup.

Discover how Part-to-Print improves costs and timelines for plastic part production

In-depth topic discussion with questions fielded during the presentation + Q&A at the end of the webinar

ATME – Take Away

If you are experiencing cycle time or warpage related problems:

Email Us Today!

#id-4011 .carousel-slider-nav-icon {

fill: #f1f1f1

}

#id-4011 .carousel-slider-nav-icon:hover {

fill: #00d1b2

}

#id-4011 .owl-prev,

#id-4011 .owl-next,

#id-4011 .carousel-slider-nav-icon {

height: 48px;

width: 48px

}

#id-4011.arrows-outside .owl-prev {

left: -48px

}

#id-4011.arrows-outside .owl-next {

right: -48px

}

#id-4011 .owl-dots .owl-dot span {

background-color: #f1f1f1;

width: 10px;

height: 10px;

}

#id-4011 .owl-dots .owl-dot.active span,

#id-4011 .owl-dots .owl-dot:hover span {

background-color: #00d1b2

}

Predict – Identify Solve

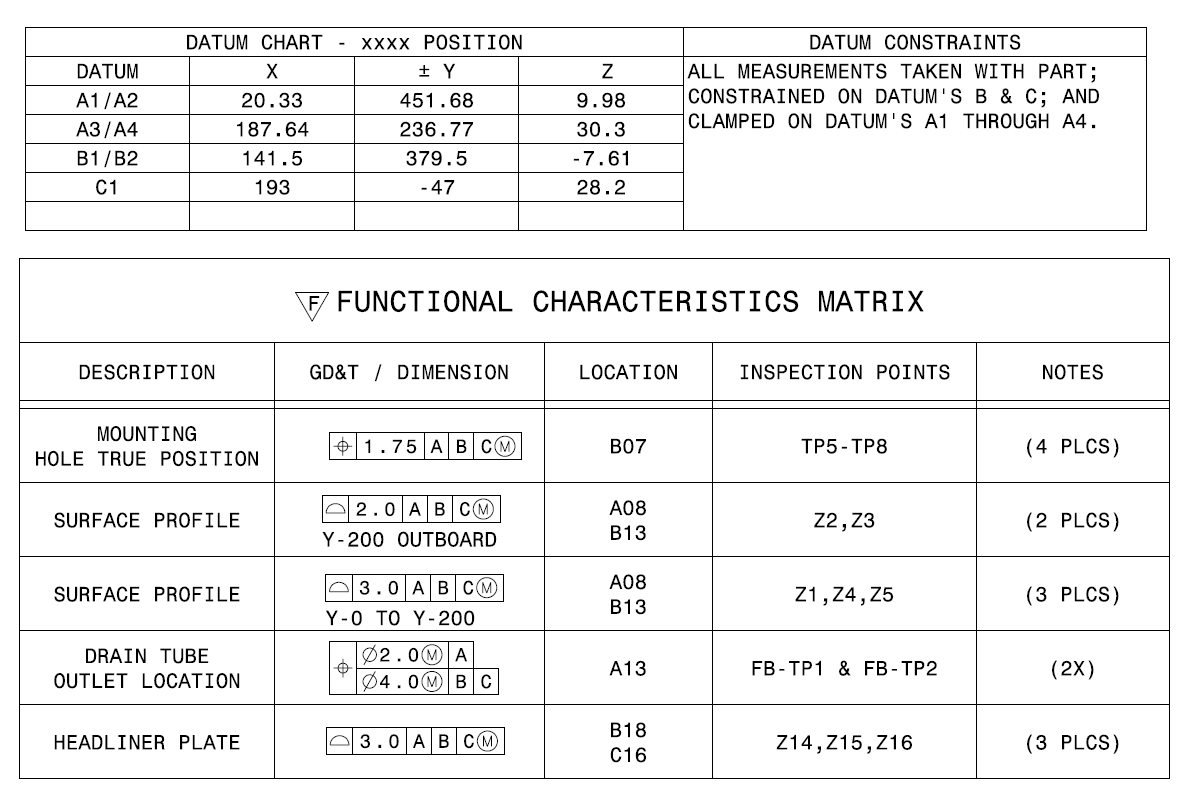

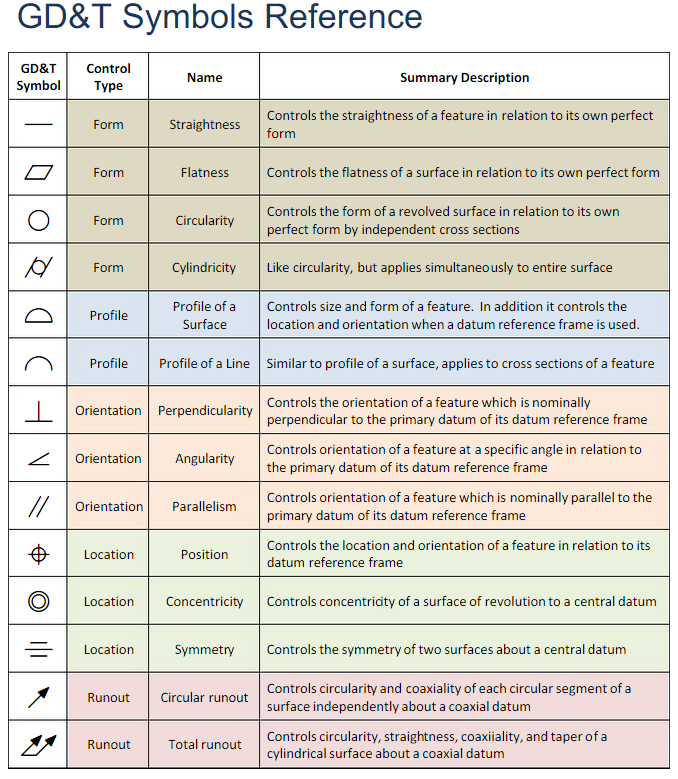

What is Part to Print?

Designer creates part design

Defines tolerances

Defines aesthetics

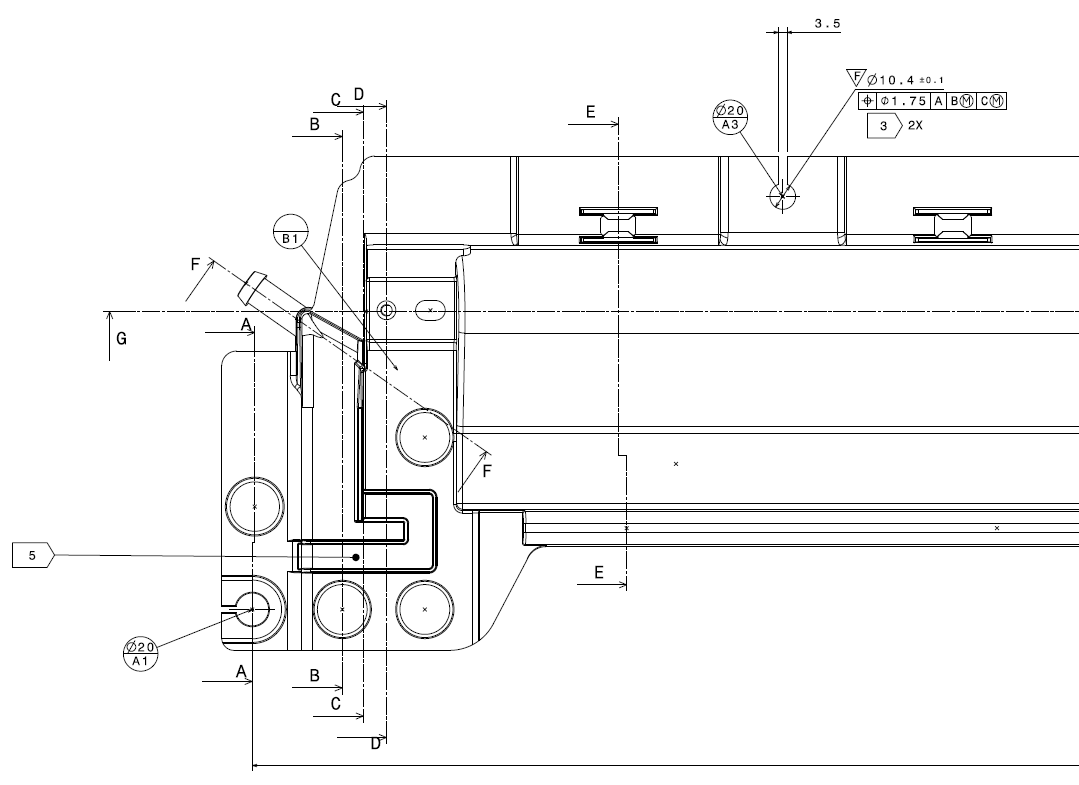

Focus on Mold Design

Gate Locations Affect Fiber Orientation

Moldmax Improved Part-to-Print

Focus on Part Design

Original Part Design

Revised Part Design #4

Focus on Material Properties

Substitute Materials Can Give Horrible Results

CRIMS Data Affects Warpage Predictions

Focus on Process Settings

CRIMS Data Affects Warpage Predictions

CRIMS Data Affects Warpage Predictions

Focus on Simulation Expertise

Example – Fixing Mesh

Summary

Leveraging Moldflow helps:

Achieve Part-to-Print

Use data to inform decisions

Identify the best way to achieve goals

Manage the timeline

Manage the budget