Ask The Moldflow Experts

Immune to Molding Problems? - Live Demo of Moldflow Software

Ask The Moldflow Experts Webinar Topic:

Immune to Molding Problems? - Live Demo of Moldflow Software

January 25th, 2022 | 12:30 PM CST

- How Moldflow solves molding problems to save time & money in your product development cycle

- Justifying purchasing software

- When and why you’ll need to outsource Moldflow analysis

ATME - Take Away

Don't Bring Me Problems...

...bring me Solutions!

-

Filling

-

Packing

-

Cooling

-

Warpage

-

Specialty Processes

Predict

Identify

Solve

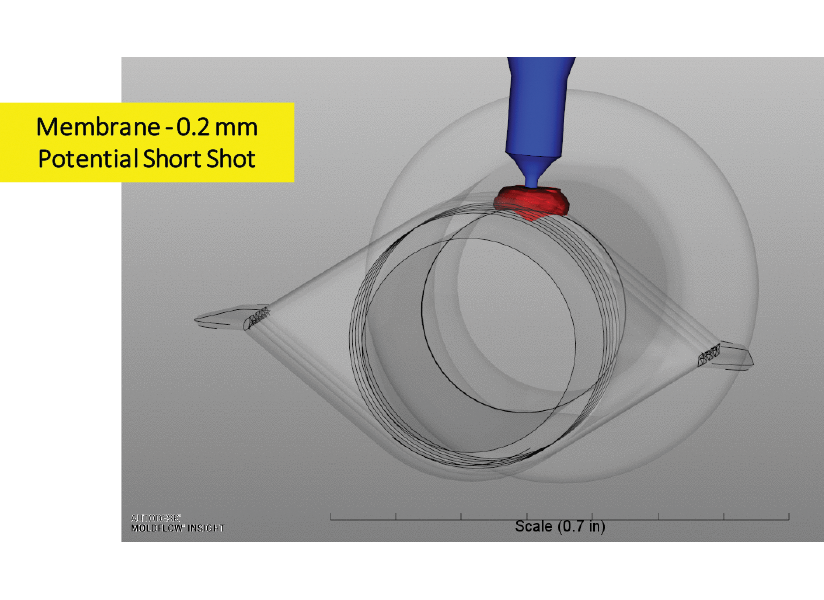

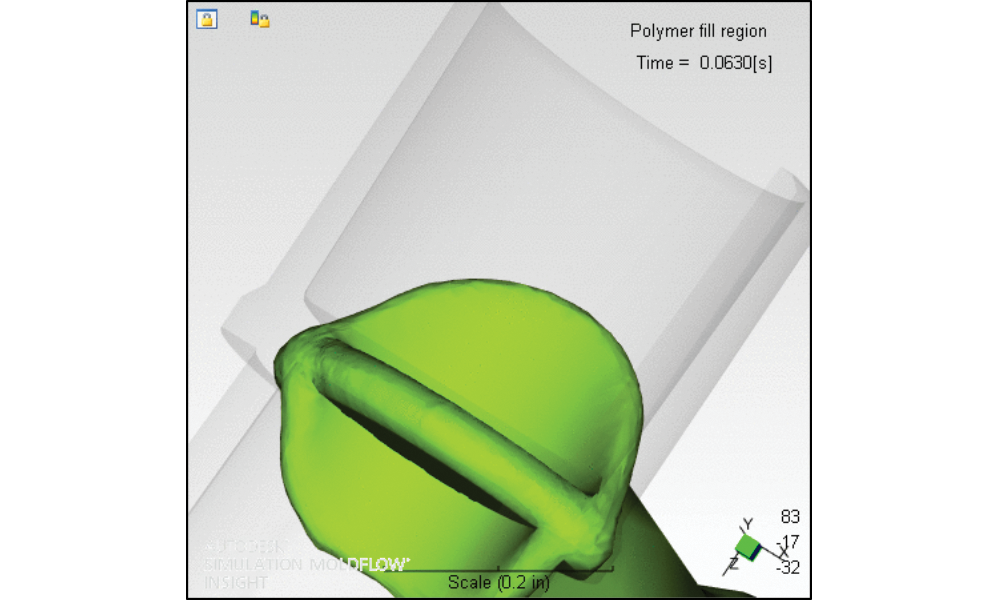

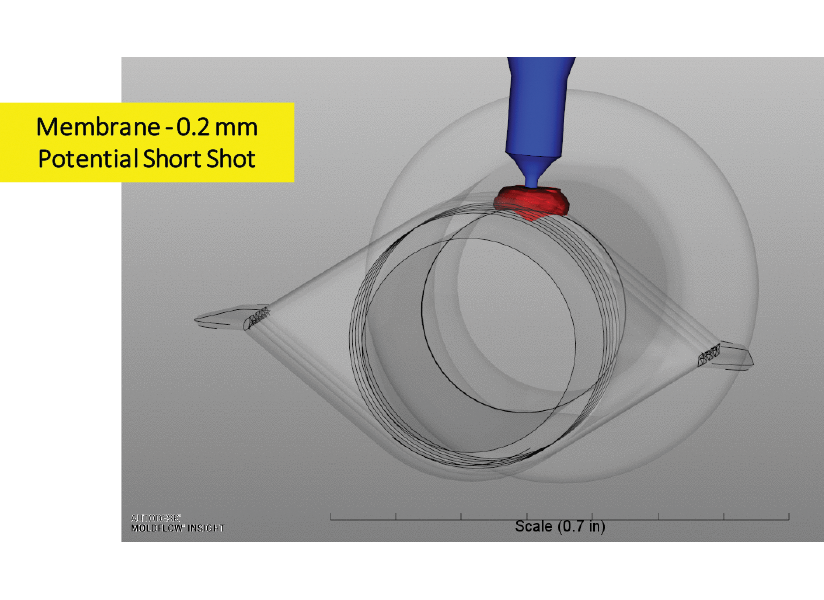

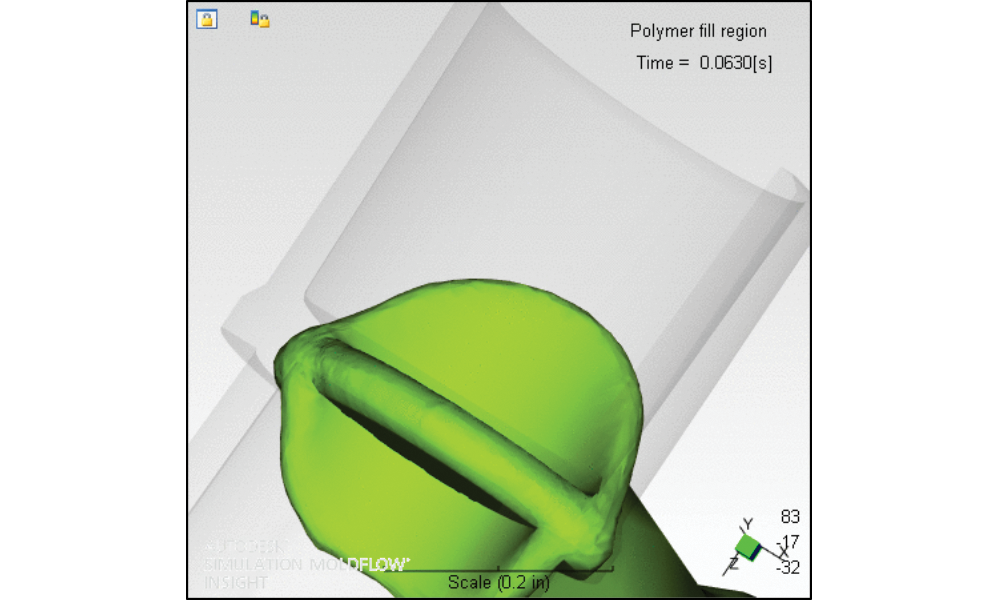

Problem #1 – Filling Thin Walls/Air Traps

Types of Problems:

- Air Traps

- Moldability

- Flow Balance

- Knit Lines

- SVG

Compression Solution

Start position thicker (1.2 mm) to fill without backfilling

Movable core compresses material to 0.2-mm membrane

Total time = 0.6 sec.

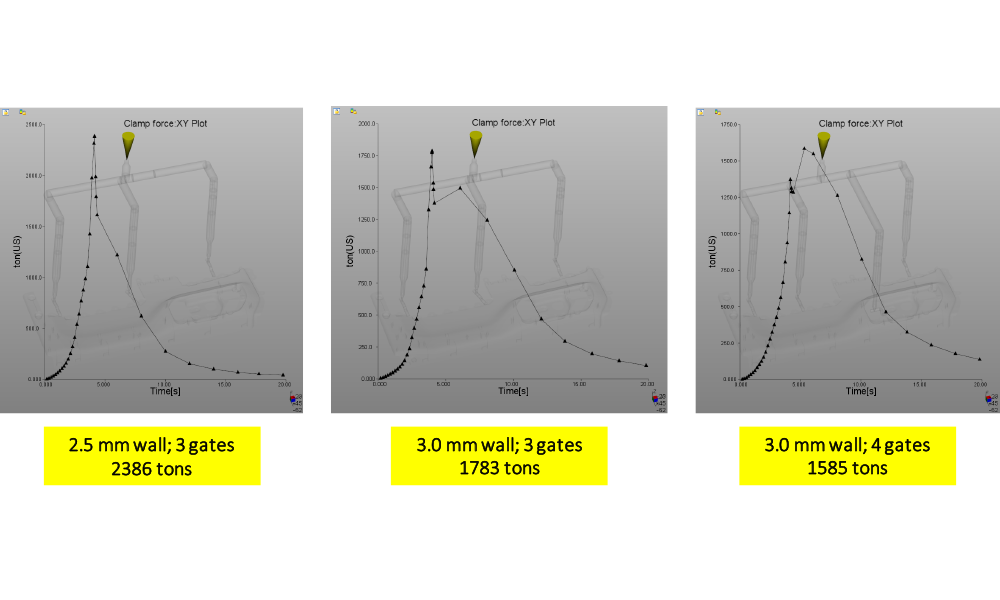

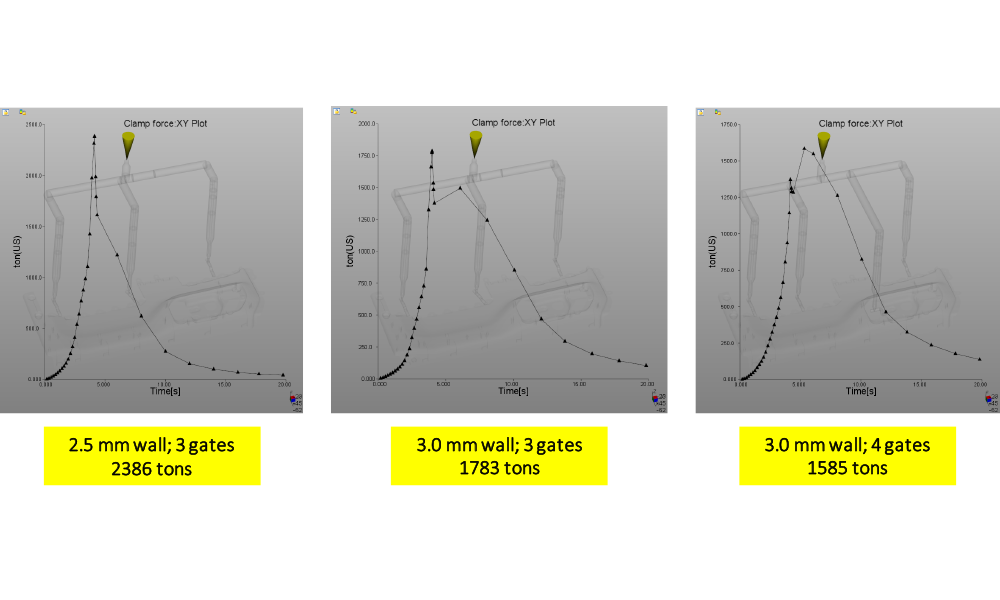

Problem #5 - Clamp Force

Types of Problems:

- Clamp Force

- Shrinkage Variation

- Sink Marks

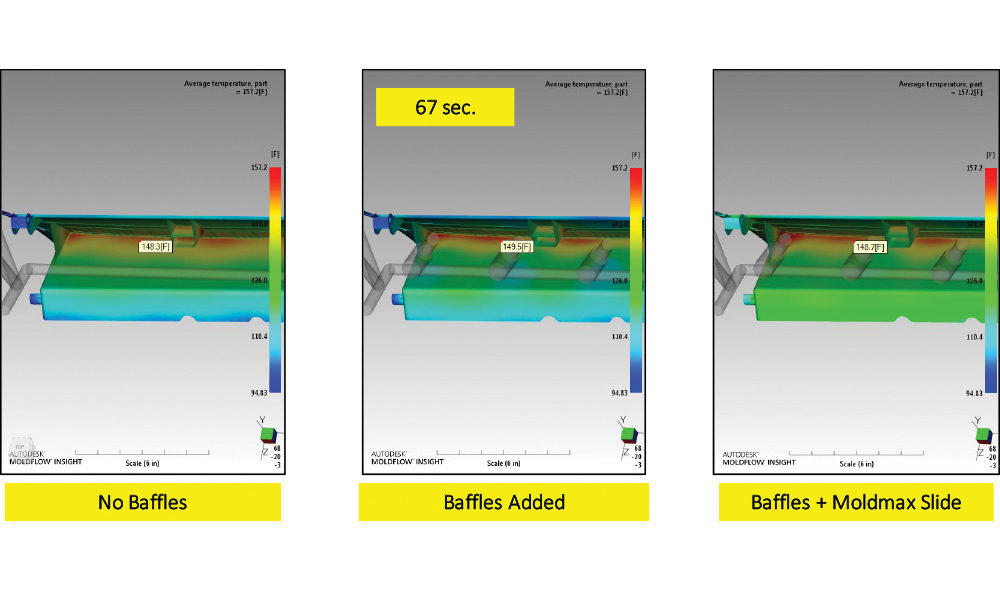

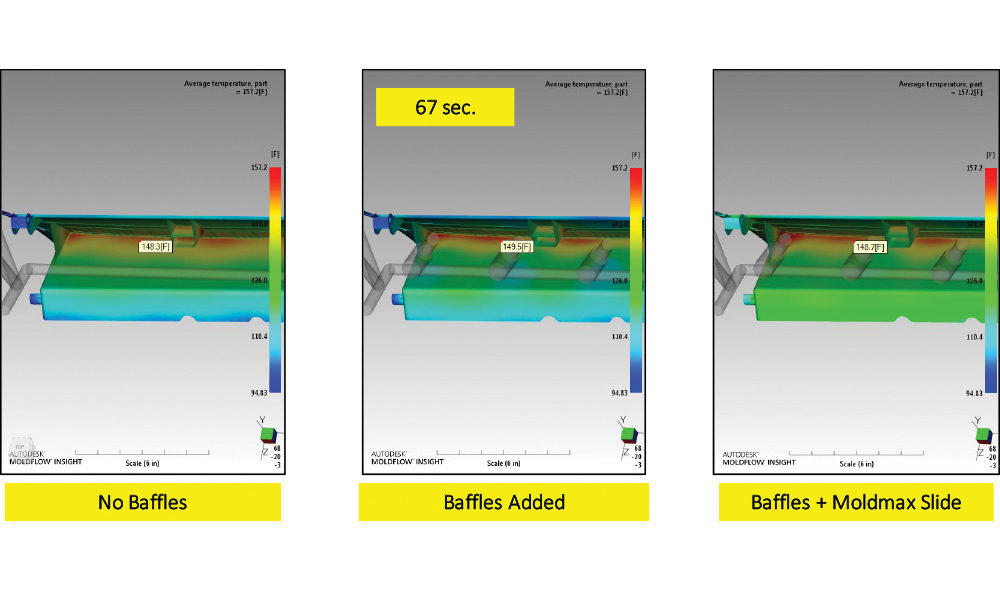

Problem #9 - Cycle Time Improvement

Types of Problems:

- Cooling Uniformity

- Cooling Inserts

- Conformal Cooling

- Circuiting

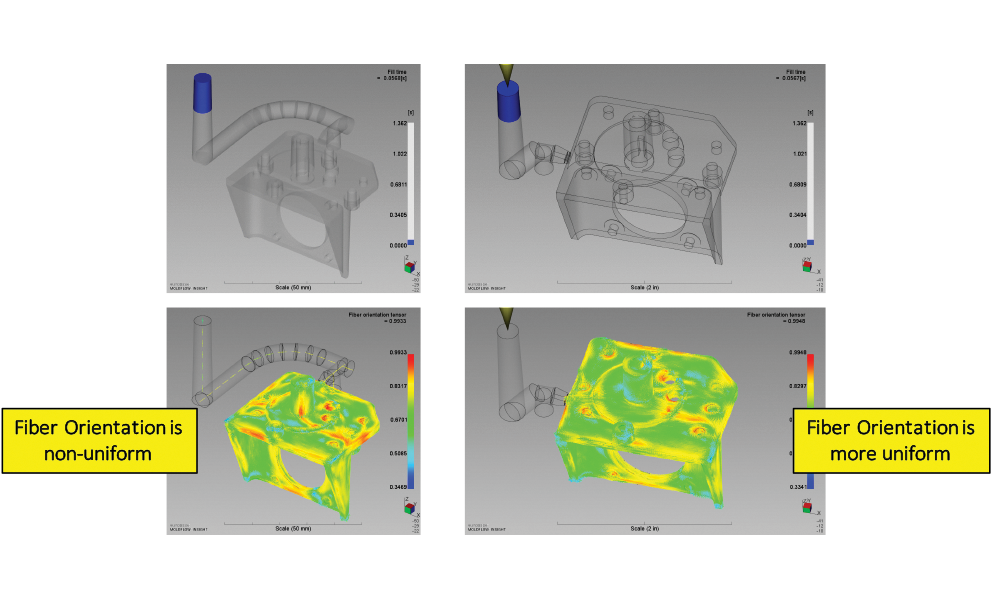

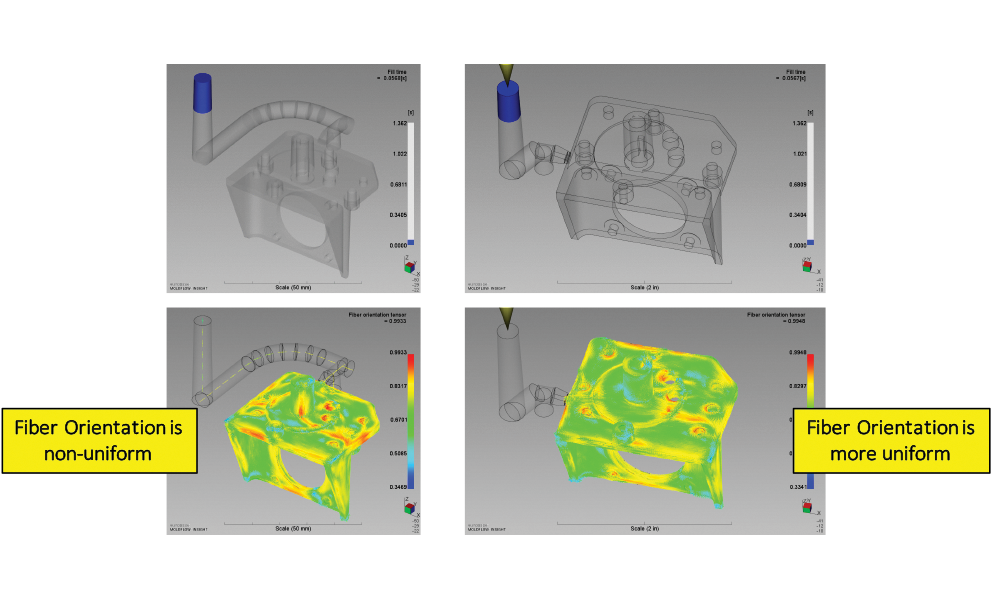

Problem #14 - Multiple Fix (Fiber Orientation)

- Perpendicularity of L-shape

- Actual = (0.005, 0.004, 0.005)

- Well within 0.010” tolerance

- Perpendicularity of boss (0.0025”)

- Actual = (0.0011, 0.0013, 0.0012)

- Well within 0.0025” tolerance

Buy Software, Outsource, or Both?

Buying Software

- Institutionalizes Moldflow

- Everyone should have some level

- Control the results

- Control the timeline

- Control simulation costs

- Want a long-term investment

- Can play more what-if

- What about ease of use and ROI

- Getting up to speed is easy

- CAE Services trains and mentors

- ROI for software purchase is relatively fast

Outsourcing

- Insight product only

- In-depth results required

- Immediate access while considering software

- Want to know if the software is accurate/useful

- Don’t have the personnel/expertise

- Even if you have software

- On-the-job training

- Learn complex techniques from experts

- Overflow capacity

Immune to Molding Problems? – Live Demo of Moldflow Software

Ask The Moldflow Experts Webinar Topic:

Immune to Molding Problems? – Live Demo of Moldflow Software

May 25th, 2021 | 12:30 PM CDT

From a financial perspective it’s easy to justify the purchase of Moldflow software as Moldflow simply offers a greater return on investment than trial & error. That’s a fact! How is this accomplished? By solving molding problems in simulation. This month we will show how easy Moldflow is to use in solving common molding problems, and why you should bring Moldflow software in-house as part of your design process.

This webinar discussed

How Moldflow solves molding problems to save time & money in your product development cycle

Justifying purchasing software

When and why you’ll need to outsource Moldflow analysis

ATME – Take Away

Call Us Today!

If you are not immune to molding problems, call or contact us today!

#id-4011 .carousel-slider-nav-icon {

fill: #f1f1f1

}

#id-4011 .carousel-slider-nav-icon:hover {

fill: #00d1b2

}

#id-4011 .owl-prev,

#id-4011 .owl-next,

#id-4011 .carousel-slider-nav-icon {

height: 48px;

width: 48px

}

#id-4011.arrows-outside .owl-prev {

left: -48px

}

#id-4011.arrows-outside .owl-next {

right: -48px

}

#id-4011 .owl-dots .owl-dot span {

background-color: #f1f1f1;

width: 10px;

height: 10px;

}

#id-4011 .owl-dots .owl-dot.active span,

#id-4011 .owl-dots .owl-dot:hover span {

background-color: #00d1b2

}

Don’t Bring Me Problems…

…bring me Solutions!

Filling

Packing

Cooling

Warpage

Specialty Processes

Predict

Identify

Solve

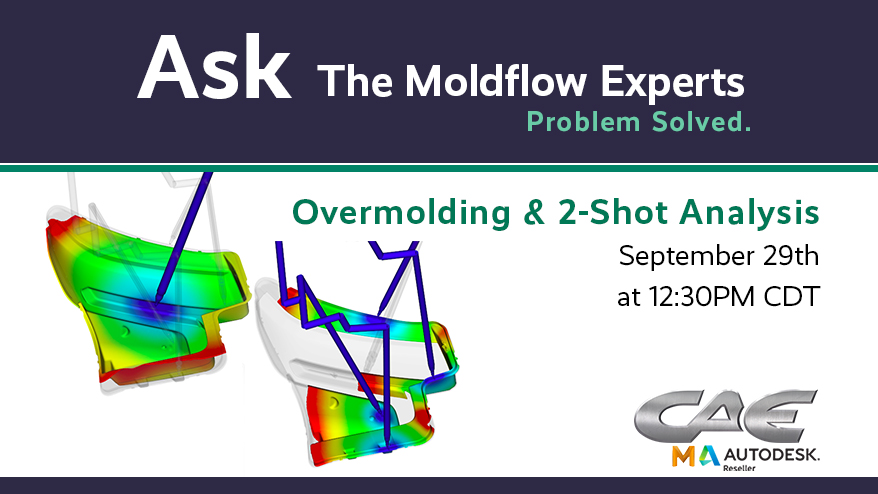

Problem #1 – Filling Thin Walls/Air Traps

Types of Problems:

Air Traps

Moldability

Flow Balance

Knit Lines

SVG

Compression Solution

Start position thicker (1.2 mm) to fill without backfilling

Movable core compresses material to 0.2-mm membrane

Total time = 0.6 sec.

Problem #5 – Clamp Force

Types of Problems:

Clamp Force

Shrinkage Variation

Sink Marks

Problem #9 – Cycle Time Improvement

Types of Problems:

Cooling Uniformity

Cooling Inserts

Conformal Cooling

Circuiting

Problem #14 – Multiple Fix (Fiber Orientation)

Perpendicularity of L-shape

Actual = (0.005, 0.004, 0.005)

Well within 0.010” tolerance

Perpendicularity of boss (0.0025”)

Actual = (0.0011, 0.0013, 0.0012)

Well within 0.0025” tolerance

Buy Software, Outsource, or Both?

Buying Software

Institutionalizes Moldflow

Everyone should have some level

Control the results

Control the timeline

Control simulation costs

Want a long-term investment

Can play more what-if

What about ease of use and ROI

Getting up to speed is easy

CAE Services trains and mentors

ROI for software purchase is relatively fast

Outsourcing

Insight product only

In-depth results required

Immediate access while considering software

Want to know if the software is accurate/useful

Don’t have the personnel/expertise

Even if you have software

On-the-job training

Learn complex techniques from experts

Overflow capacity