Thank you for stopping by

from Plastics News Daily

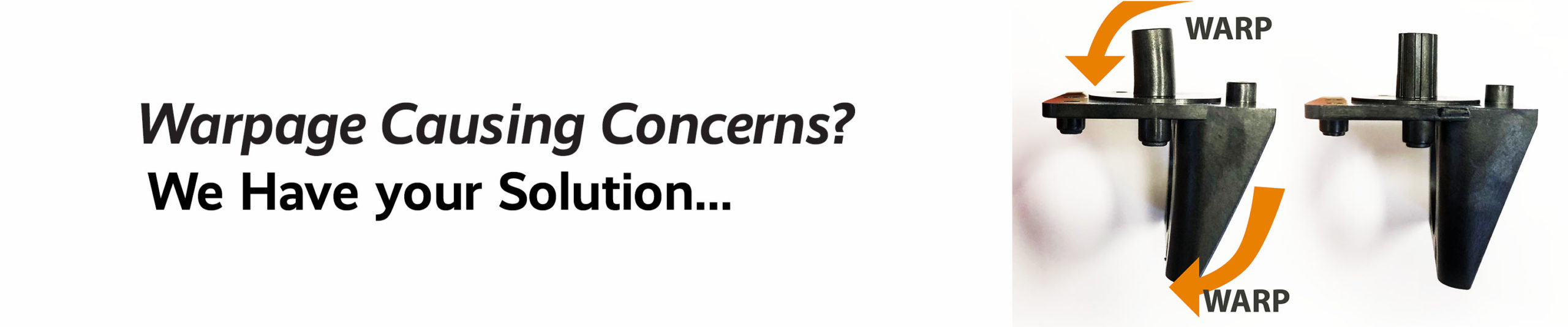

Tight Tolerances Concerns?

Call or Contact us Today!

AND scroll down to see how we solved a

tight tolerance warpage problem with windage.

ATME - Take Away

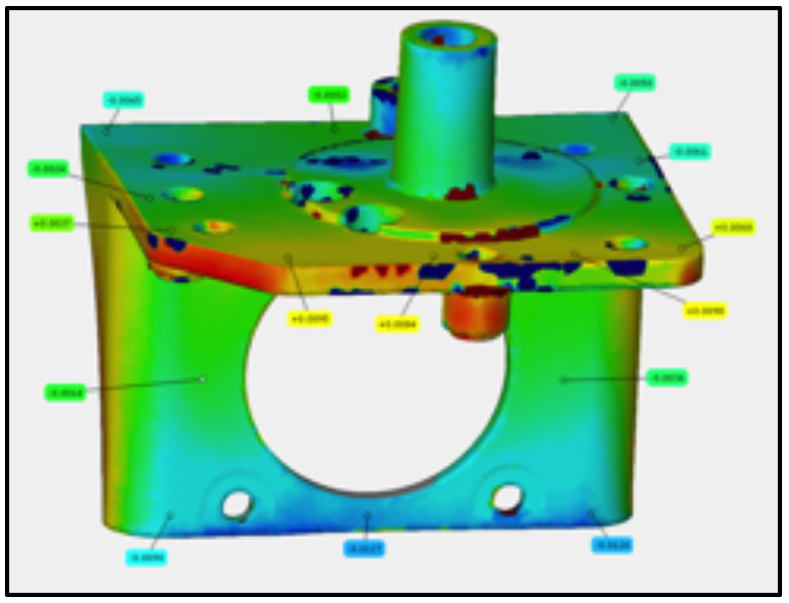

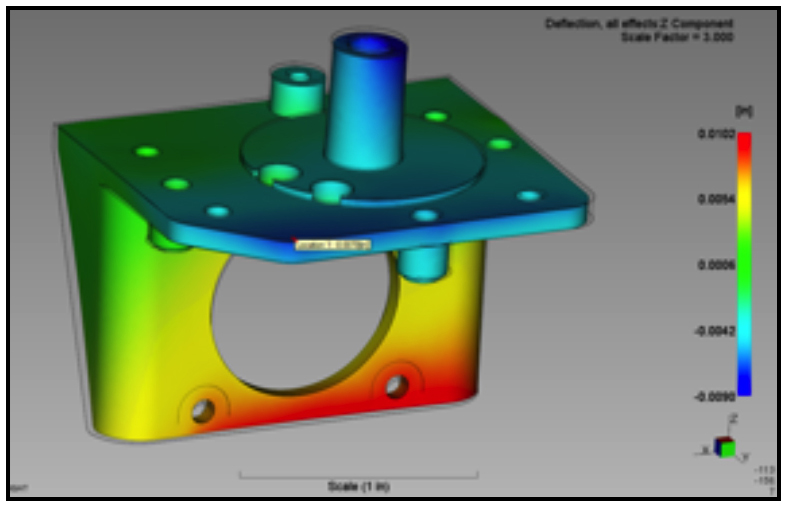

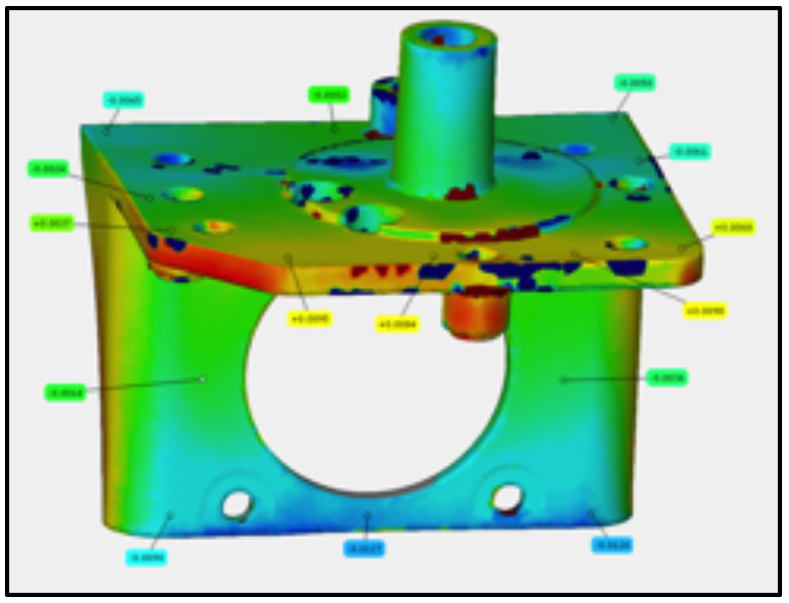

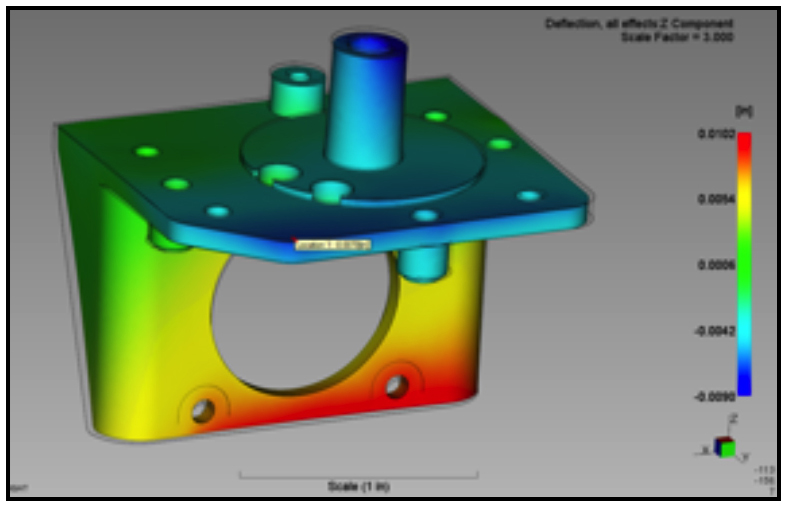

Step 1 - Correlation Existing Warpage

- Old material deck predicted right trend, wrong magnitude

- New material deck predicted trend and magnitude correctly

- Determined cause of warpage to be fiber orientation

Old Material Deck

Max deviation = 0.014”

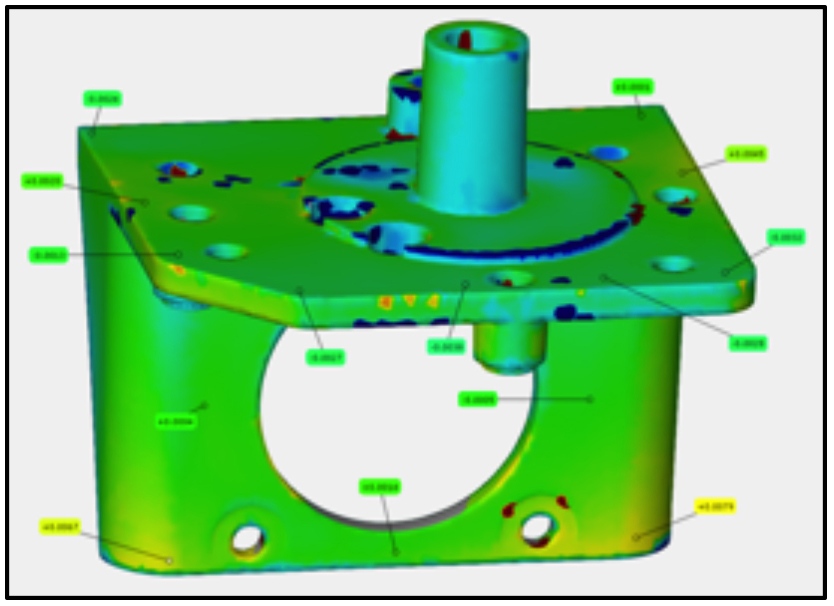

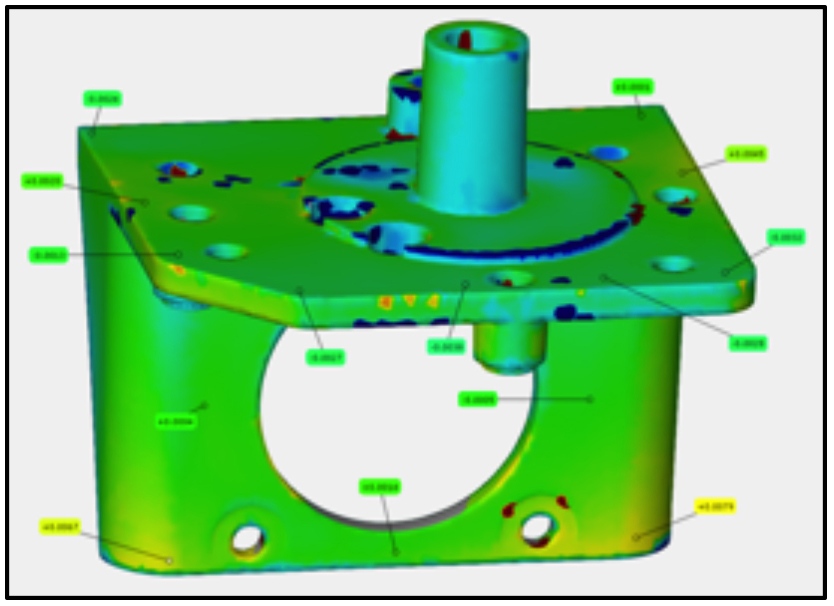

New Material Deck

Max deviation = 0.008”

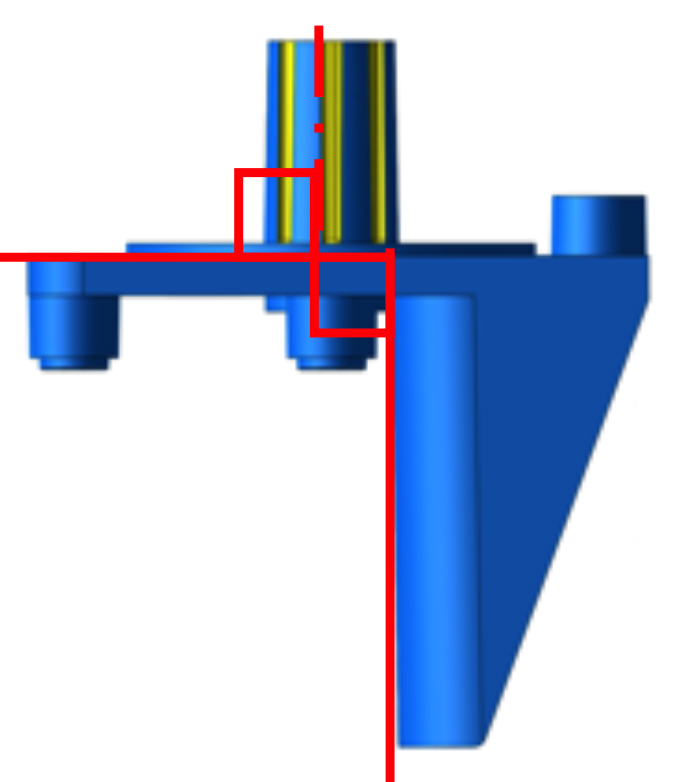

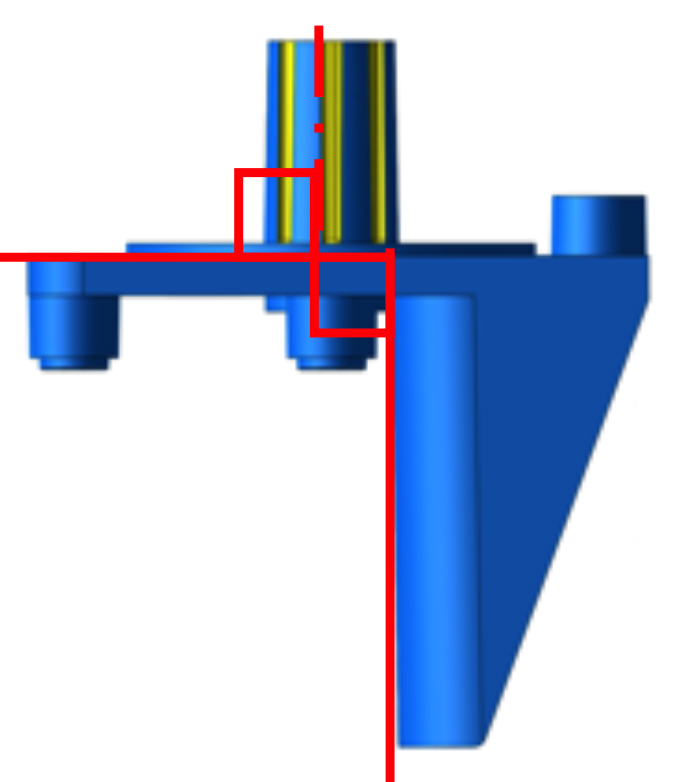

Step 2 – Minimize Warpage

- Change Gate Location for more favorable fiber alignment

- Warpage reduced slightly, but not within tolerance

- Sink marks eliminated

Max. Deflections

Downward - 0.0070”

Inward – 0.0099”

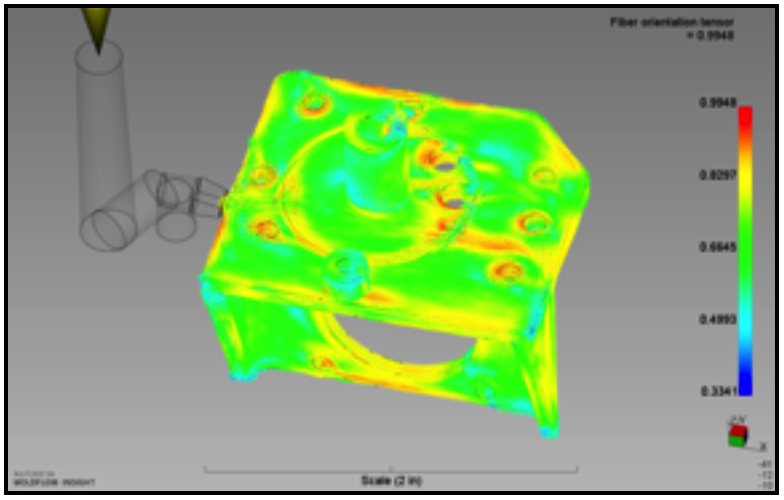

Fiber Orientation More Uniform Across Part

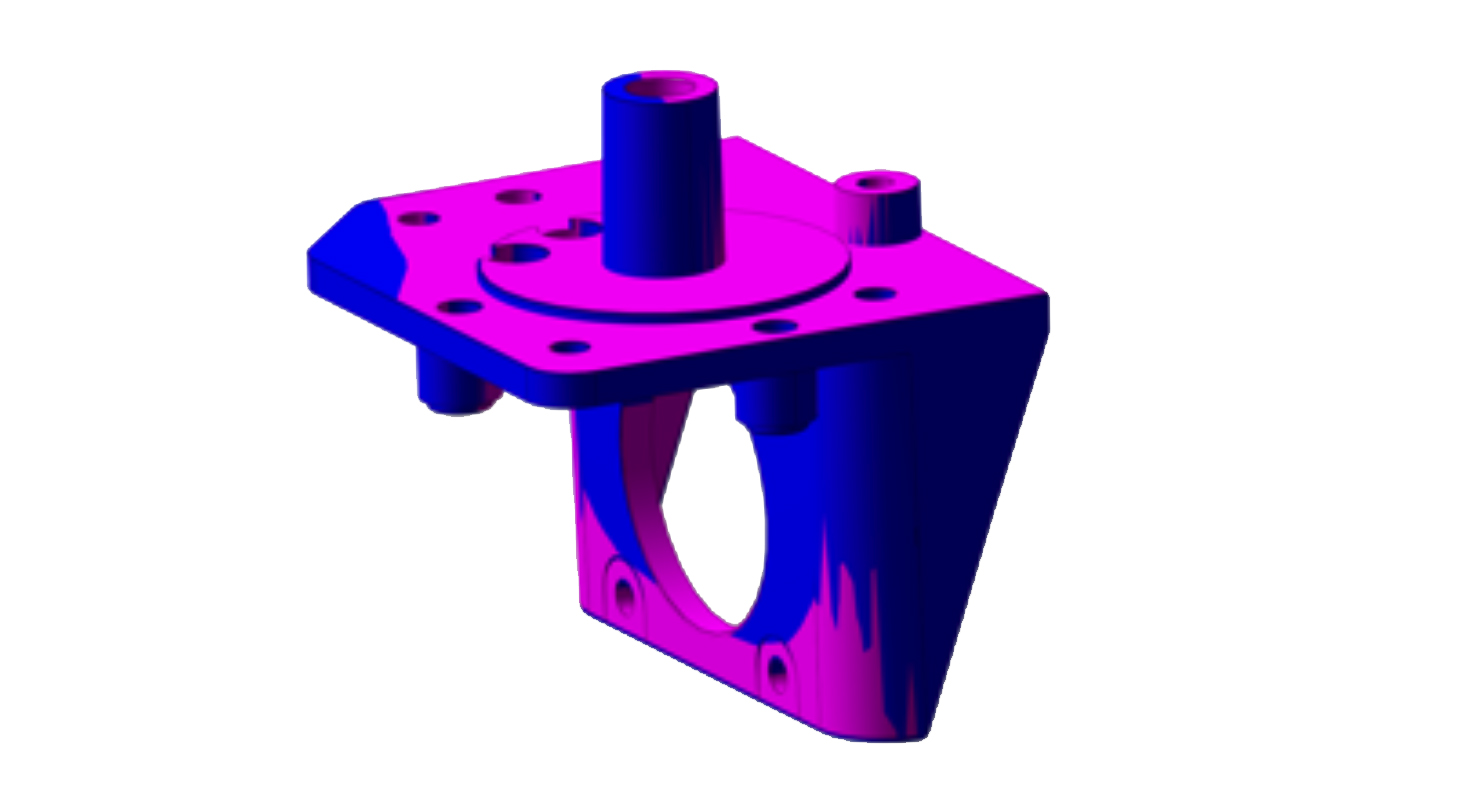

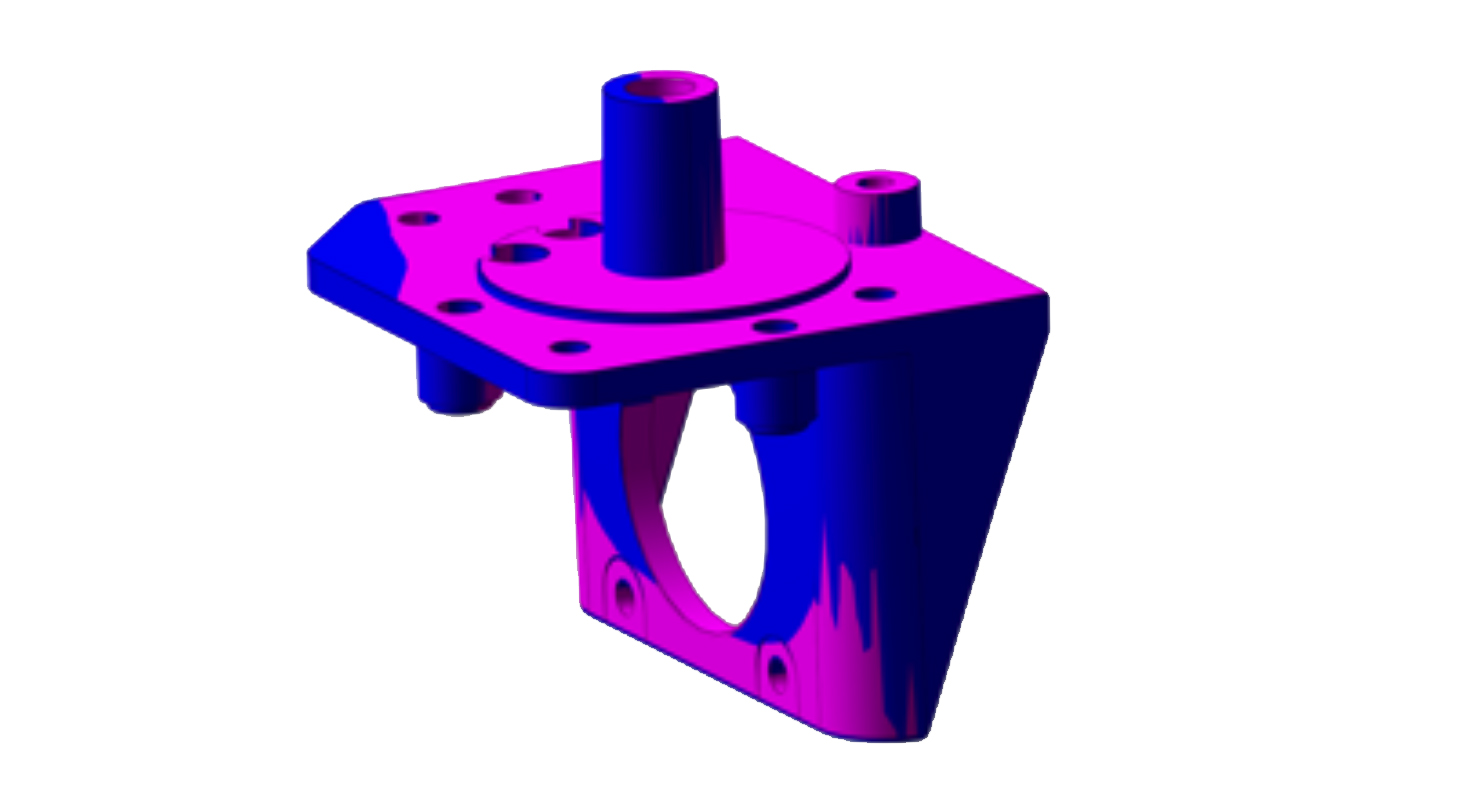

Step 3 – Use Windage to Fix Warpage

- Determine Windage Factor

- Decide on Shrinkage Number

- Morph the Part (avoid die lock)

- Confirm in Moldflow

- One week to complete analysis, material testing, and delivery of morphed windage file.

Purple = Nominal

Blue = Windage

Step 4 - Final Molded Samples - Dimensions

- Perpendicularity of L-shape

- Actual = (0.005, 0.004, 0.005)

- Well within 0.010” tolerance

- Perpendicularity of boss (0.0025”)

- Actual = (0.0011, 0.0013, 0.0012)

- Well within 0.0025” tolerance

First

Last

Email*

Phone*Comments*CAPTCHA

jQuery(document).ready(function($){gformInitSpinner( 2, ‘https://caeservices.com/wp-content/plugins/gravityforms/images/spinner.gif’ );jQuery(‘#gform_ajax_frame_2’).on(‘load’,function(){var contents = jQuery(this).contents().find(‘*’).html();var is_postback = contents.indexOf(‘GF_AJAX_POSTBACK’) >= 0;if(!is_postback){return;}var form_content = jQuery(this).contents().find(‘#gform_wrapper_2’);var is_confirmation = jQuery(this).contents().find(‘#gform_confirmation_wrapper_2’).length > 0;var is_redirect = contents.indexOf(‘gformRedirect(){‘) >= 0;var is_form = form_content.length > 0 && ! is_redirect && ! is_confirmation;var mt = parseInt(jQuery(‘html’).css(‘margin-top’), 10) + parseInt(jQuery(‘body’).css(‘margin-top’), 10) + 100;if(is_form){jQuery(‘#gform_wrapper_2’).html(form_content.html());if(form_content.hasClass(‘gform_validation_error’)){jQuery(‘#gform_wrapper_2’).addClass(‘gform_validation_error’);} else {jQuery(‘#gform_wrapper_2’).removeClass(‘gform_validation_error’);}setTimeout( function() { /* delay the scroll by 50 milliseconds to fix a bug in chrome */ jQuery(document).scrollTop(jQuery(‘#gform_wrapper_2’).offset().top – mt); }, 50 );if(window[‘gformInitDatepicker’]) {gformInitDatepicker();}if(window[‘gformInitPriceFields’]) {gformInitPriceFields();}var current_page = jQuery(‘#gform_source_page_number_2’).val();gformInitSpinner( 2, ‘https://caeservices.com/wp-content/plugins/gravityforms/images/spinner.gif’ );jQuery(document).trigger(‘gform_page_loaded’, [2, current_page]);window[‘gf_submitting_2’] = false;}else if(!is_redirect){var confirmation_content = jQuery(this).contents().find(‘.GF_AJAX_POSTBACK’).html();if(!confirmation_content){confirmation_content = contents;}setTimeout(function(){jQuery(‘#gform_wrapper_2’).replaceWith(confirmation_content);jQuery(document).scrollTop(jQuery(‘#gf_2’).offset().top – mt);jQuery(document).trigger(‘gform_confirmation_loaded’, [2]);window[‘gf_submitting_2’] = false;}, 50);}else{jQuery(‘#gform_2’).append(contents);if(window[‘gformRedirect’]) {gformRedirect();}}jQuery(document).trigger(‘gform_post_render’, [2, current_page]);} );} ); jQuery(document).bind(‘gform_post_render’, function(event, formId, currentPage){if(formId == 2) {if(typeof Placeholders != ‘undefined’){

Placeholders.enable();

}jQuery(‘#input_2_4’).mask(‘(999) 999-9999’).bind(‘keypress’, function(e){if(e.which == 13){jQuery(this).blur();} } );} } );jQuery(document).bind(‘gform_post_conditional_logic’, function(event, formId, fields, isInit){} ); jQuery(document).ready(function(){jQuery(document).trigger(‘gform_post_render’, [2, 1]) } );

Thank you for stopping by from Plastics News Daily

Tight Tolerances Concerns?Call or Contact us Today!

AND scroll down to see how we solved a tight tolerance warpage problem with windage.

ATME – Take Away

#id-4011 .carousel-slider-nav-icon {

fill: #f1f1f1

}

#id-4011 .carousel-slider-nav-icon:hover {

fill: #00d1b2

}

#id-4011 .owl-prev,

#id-4011 .owl-next,

#id-4011 .carousel-slider-nav-icon {

height: 48px;

width: 48px

}

#id-4011.arrows-outside .owl-prev {

left: -48px

}

#id-4011.arrows-outside .owl-next {

right: -48px

}

#id-4011 .owl-dots .owl-dot span {

background-color: #f1f1f1;

width: 10px;

height: 10px;

}

#id-4011 .owl-dots .owl-dot.active span,

#id-4011 .owl-dots .owl-dot:hover span {

background-color: #00d1b2

}

Step 1 – Correlation Existing Warpage

Old material deck predicted right trend, wrong magnitude

New material deck predicted trend and magnitude correctly

Determined cause of warpage to be fiber orientation

Old Material Deck

Max deviation = 0.014”

New Material Deck

Max deviation = 0.008”

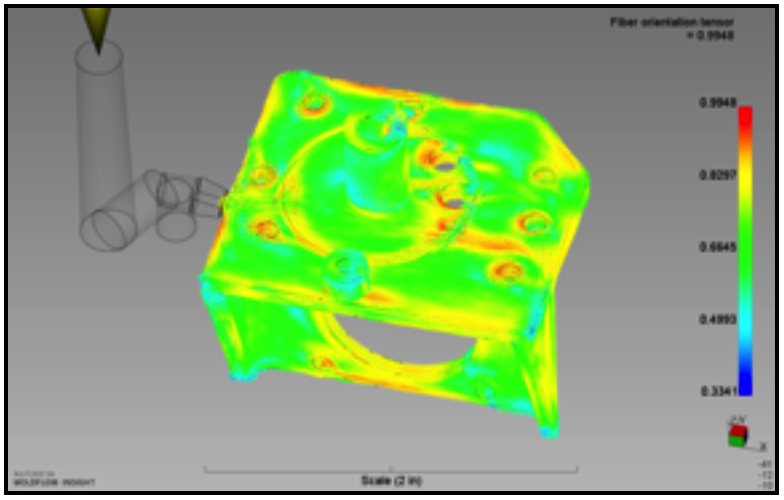

Step 2 – Minimize Warpage

Change Gate Location for more favorable fiber alignment

Warpage reduced slightly, but not within tolerance

Sink marks eliminated

Max. Deflections

Downward – 0.0070”

Inward – 0.0099”

Fiber Orientation More Uniform Across Part

Step 3 – Use Windage to Fix Warpage

Determine Windage Factor

Decide on Shrinkage Number

Morph the Part (avoid die lock)

Confirm in Moldflow

One week to complete analysis, material testing, and delivery of morphed windage file.

Purple = NominalBlue = Windage

Step 4 – Final Molded Samples – Dimensions

Perpendicularity of L-shape

Actual = (0.005, 0.004, 0.005)

Well within 0.010” tolerance

Perpendicularity of boss (0.0025”)

Actual = (0.0011, 0.0013, 0.0012)

Well within 0.0025” tolerance